Preparation method of nano barium carbonate slurry

A nano-barium carbonate, barium carbonate technology, applied in directions such as barium carbonate, calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of low use efficiency, low reaction rate, inability to effectively remove sodium chloride sulfate, etc., To achieve the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

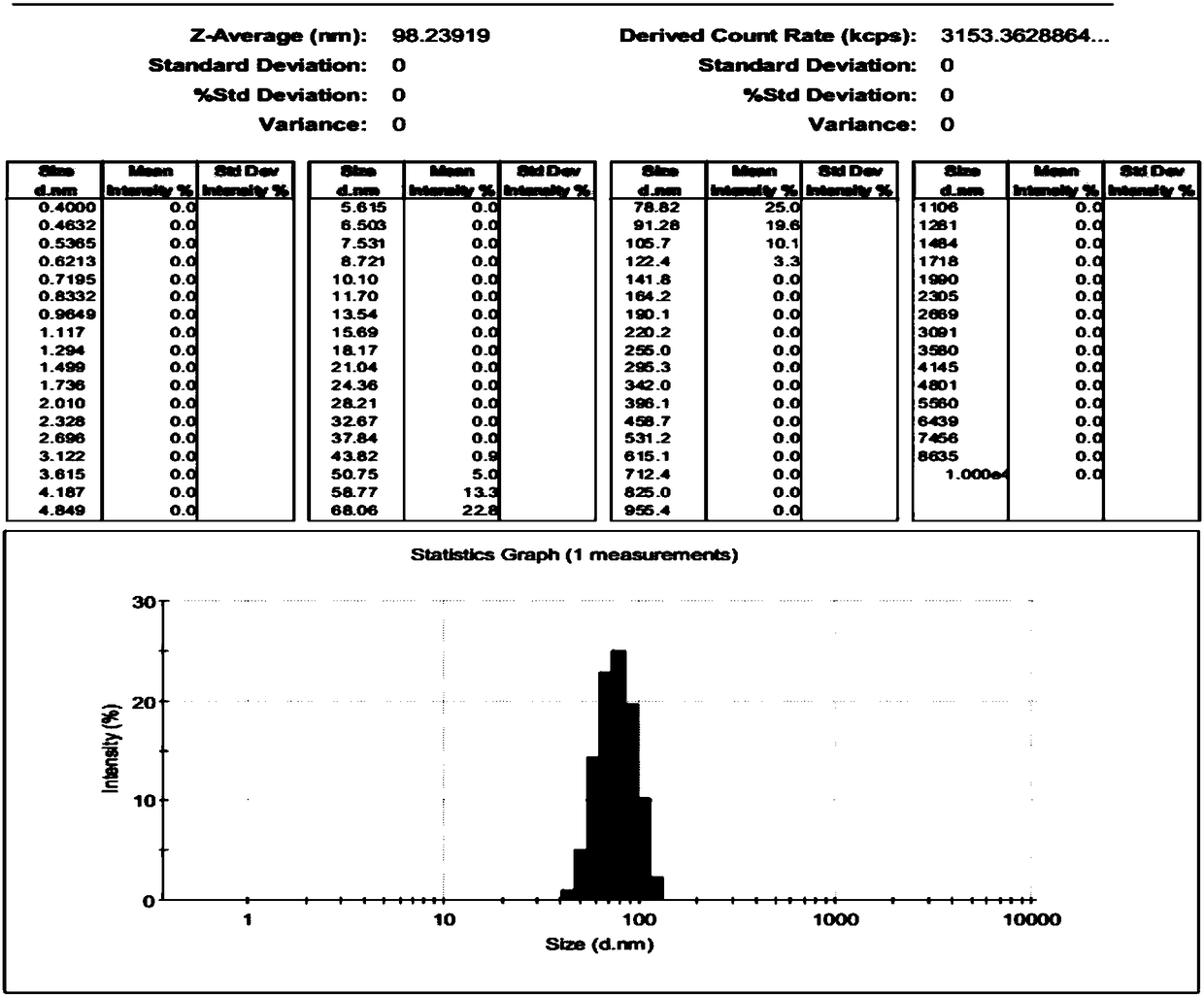

[0020] Use the stainless steel mixing tank of 200L, add barium carbonate 100Kg (the average particle diameter that Guizhou Hongxing produces is the light barium carbonate of 2.67 μm), add 100 kilograms of deionized waters, add 2 kilograms of pentaerythritol again, stir evenly in the stainless steel mixing bucket, Then in the 1-4# ceramic horizontal sand mill (Peller nano sand mill PHN-10) that is pumped into 10L serial mode setting successively with metering pump, in the ceramic horizontal sand mill, be added with zirconia beads ( Zirmil Y produced by Saint-Gobain Sip), wherein 1-2# sand mills add zirconia balls with a particle size of 800-1200 μm, 3-4# sand mills add zirconia balls with a particle size of 100-300 μm, and carbonic acid The barium slurry is firstly ground with the 1# sand mill, then the second level of grinding through the 2# sand mill, then the third level of grinding through the 3# sand mill, and finally the fourth level of grinding through the 4# sand mill. ...

Embodiment 2

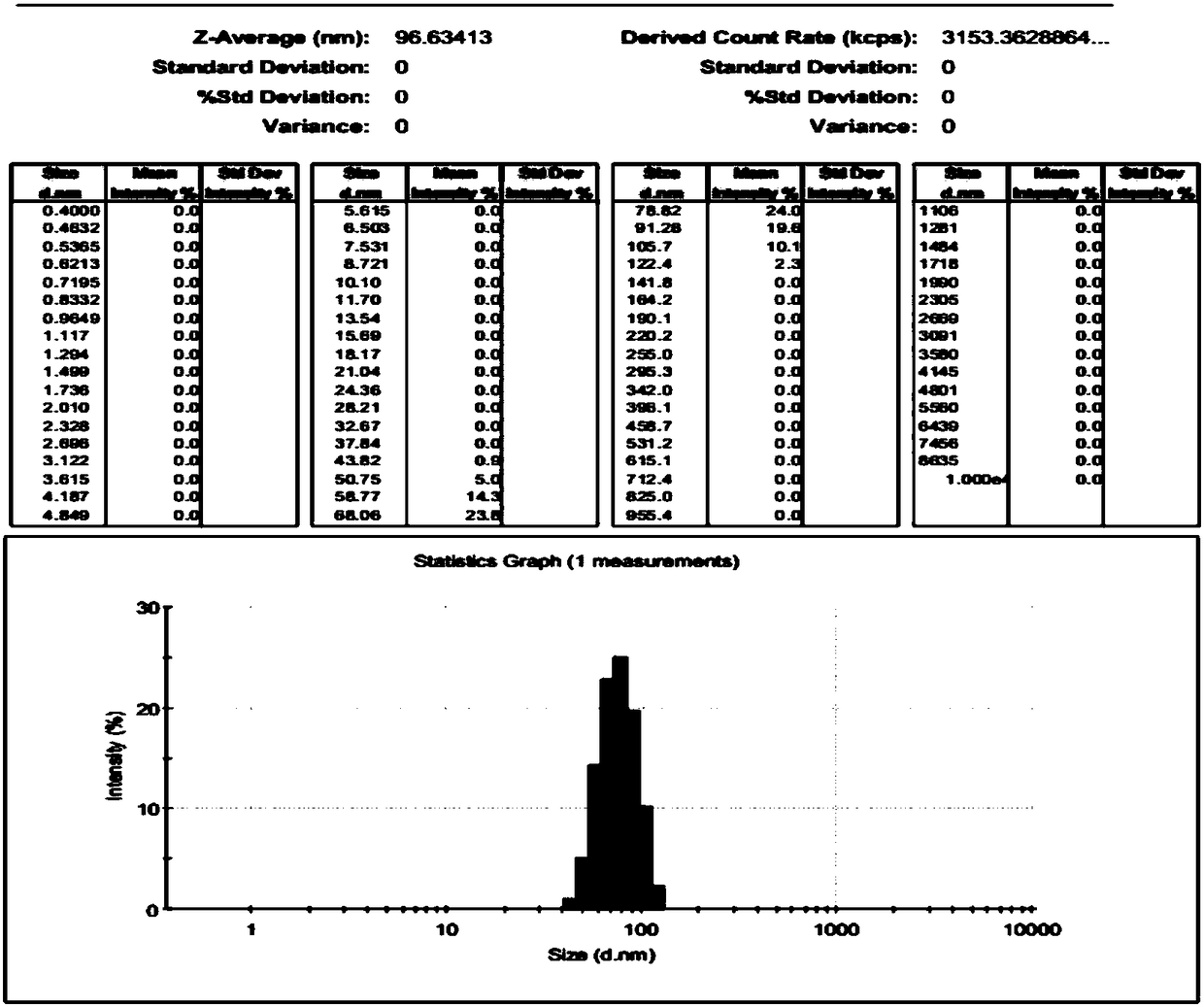

[0022] With reference to Example 1, the difference is that pentaerythritol is replaced by sodium polyacrylate to obtain nanoscale barium carbonate slurry, and the particle size measurement results are shown in image 3 Among them, the average particle size is 96.6nm.

Embodiment 3

[0029] Referring to Example 1, the difference is that the pentaerythritol is 1 kg, and the flow rate of the metering pump is controlled at 2 L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com