Deep disposal process for biochemical tail water of chemical industry

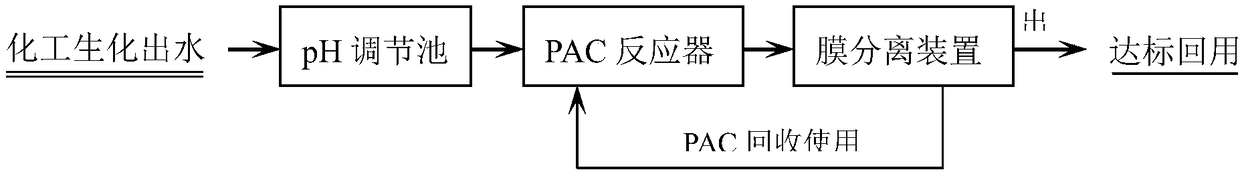

An advanced treatment and biochemical technology, applied in biological water/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of large amount of adsorbent, high operating cost, secondary pollution, etc. The effect of adsorption removal rate, fast settling performance and not easy to run off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The treated biochemical tail water quality of a coking plant is COD Cr =140~200mg / L, SS≤150mg / L, TN=18~45mg / L, NH 3 -N=10-25mg / L, TP=2.5~4.5mg / L, chromaticity 80-100 times, pH=7.0~8.5.

[0033] The specific steps for treating the above-mentioned water quality wastewater by using the wastewater treatment process provided by the embodiment of the present invention are as follows: first add activated sludge from a sewage plant to the pH adjustment tank according to 8% of the amount of wastewater, and the air-to-water ratio is 2:1. Aeration intensity: Aerate for 60 hours, add a small amount of sodium bicarbonate and sodium hydroxide to adjust the pH to about 7.0. Wastewater containing activated sludge is pumped from the pH adjustment tank into the water inlet tank of the PAC reactor, and then PAC powder is added to the reaction zone of the PAC reactor, with a dosage of 22-25kg / m 3 For waste water, aerate for 6 hours according to the aeration intensity of the air-water rat...

Embodiment 2

[0035] The quality of the biochemical tail water treated by a fine chemical enterprise is COD Cr =170~200mg / L, SS≤120mg / L, TN=20~38mg / L, NH 3 -N=10~20mg / L, TP=2.0~4.5mg / L, chromaticity 60~80 times, pH=6.0~8.0.

[0036] The specific steps for treating the above-mentioned water quality wastewater by using the wastewater treatment process provided by the embodiment of the present invention are as follows: first add activated sludge from a sewage plant to the pH adjustment tank according to 6% of the wastewater amount, and the air-water ratio is 2:1. Aeration intensity: Aerate for 48 hours, add a small amount of sodium bicarbonate and sodium hydroxide to adjust the pH value to about 7.0. Wastewater containing activated sludge is pumped from the pH adjustment tank into the water inlet tank of the PAC reactor, and then PAC powder is added to the reaction zone of the PAC reactor, with a dosage of 20-23kg / m 3For wastewater, aerate for 5 hours at an aeration intensity of 2.5:1. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com