Water-dispersed diatomite composite flocculating dehydrating agent and application thereof

A diatomite, dispersing technology, applied in the direction of dehydration/drying/concentrating sludge treatment, etc., can solve the problem of product flocculation performance decline and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

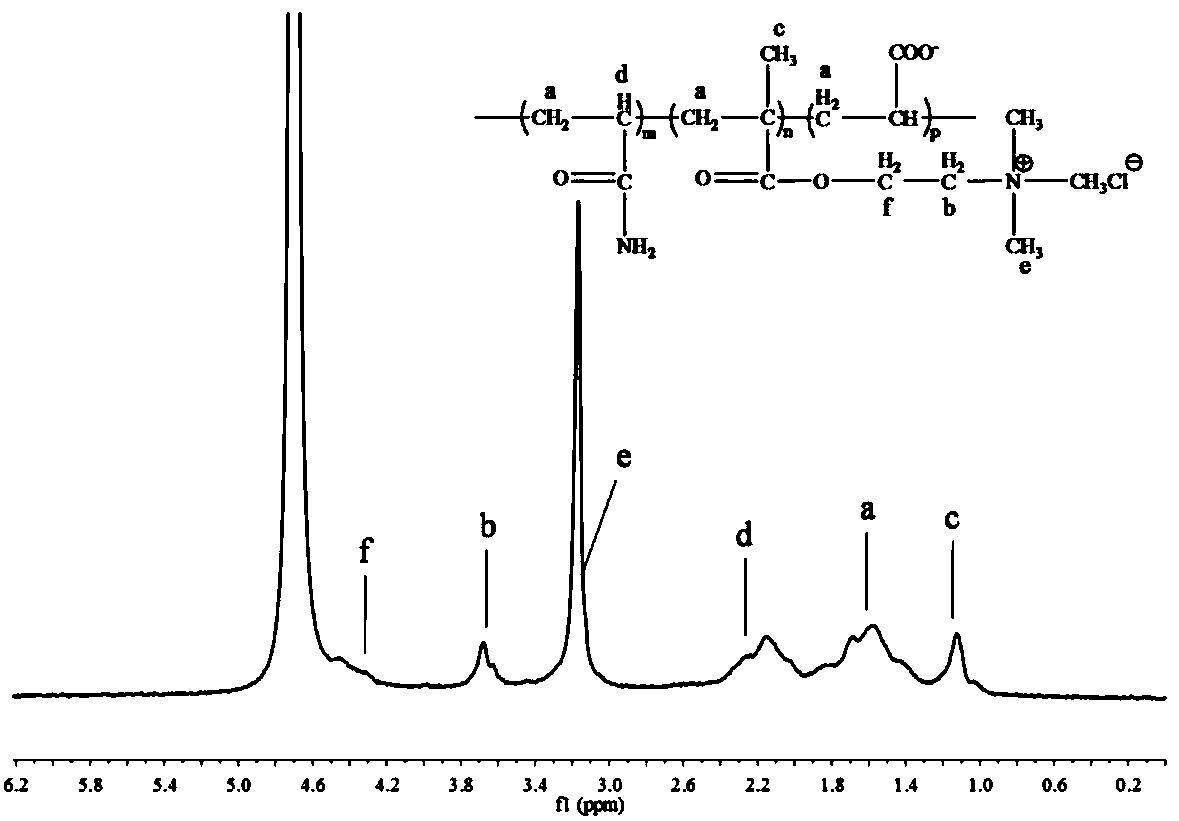

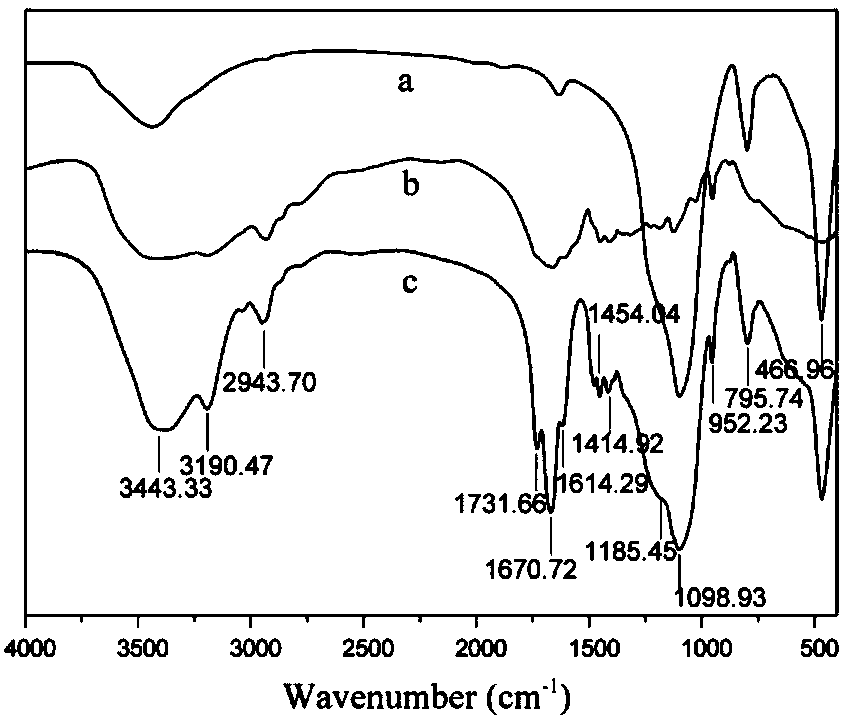

Method used

Image

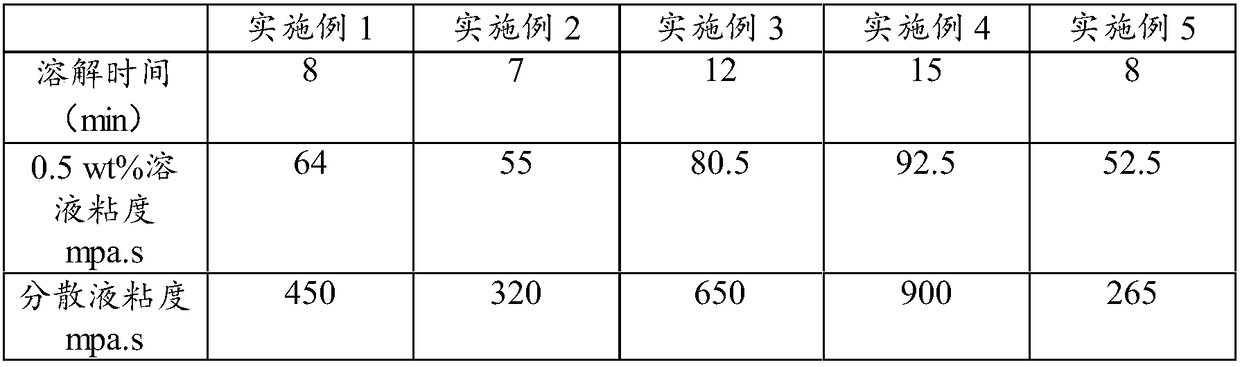

Examples

Embodiment 1

[0051] In a sodium chloride aqueous solution with a mass concentration of 25%, poly(dimethyldiallylammonium chloride) with a molecular weight of 250,000 is used as a dispersion stabilizer, and zwitterionic monomers (acrylic acid and acryloxyethyl Trimethylammonium chloride) and acrylamide are put into the reaction flask at a ratio of 1:2 (molar ratio), in which the ratio of acrylic acid and acryloxyethyltrimethylammonium chloride is 1:1 (molar ratio), Add water, add diatomaceous earth (the amount of diatomaceous earth added is 25% of the total mass of the monomer), adjust its mass concentration to 22.6%; then add the initiator ammonium persulfate with 0.1% of the monomer mass and proceed at 50°C Free radical copolymerization, the polymerization time is 12 hours, to obtain a white milky dispersion, that is, a water-dispersed diatomite composite flocculating dehydrating agent.

[0052] The product prepared in this example is used to treat papermaking sludge with a solid content of ...

Embodiment 2

[0060] In an aqueous potassium chloride solution with a mass concentration of 40%, poly(vinylpyrrolidone) with a molecular weight of 450,000 is used as a dispersion stabilizer, and zwitterionic monomers (methacrylic acid and methacryloxyethyl trimethyl Ammonium chloride) and acrylamide are put into the reaction flask at a ratio of 1:5 (molar ratio), wherein the ratio of methacrylic acid and methacryloxyethyl trimethylammonium chloride is 1:2.2 (molar ratio) , Add water, add diatomaceous earth (the amount of diatomaceous earth added is 40% of the total mass of the monomer), adjust its mass concentration to 30.5%; then add 0.5% of the monomer mass of initiator ammonium persulfate at 50°C Carry out free radical copolymerization, and the polymerization time is 8 hours, to obtain a white milky dispersion, that is, a water-dispersed diatomite composite flocculating dehydrating agent.

[0061] The product prepared in this example is used to treat leather sludge with a solid content of 3...

Embodiment 3

[0063] In an aqueous solution of ammonium sulfate with a mass concentration of 30%, poly(methacryloxyethyltrimethylammonium chloride) with a molecular weight of 800,000 is used as a dispersion stabilizer, and zwitterionic monomers (acrylic acid and acryloxy Ethyl benzyl ammonium chloride) and acrylamide were put into the reaction flask at a ratio of 1:8 (molar ratio), in which the ratio of methacrylic acid and methacryloxyethyl benzyl ammonium chloride was 1:3.5 ( Molar ratio), add water, add diatomaceous earth (the amount of diatomaceous earth added is 15% of the total mass of the monomer), adjust its mass concentration to 18%; then add 2% of the monomer mass of the initiator ammonium persulfate to Free radical copolymerization is carried out at 60°C, and the polymerization time is 10 hours, to obtain a white milky dispersion, that is, a water-dispersed diatomite composite flocculating dehydrating agent.

[0064] The product prepared in this example is used to treat leather slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com