Formula and preparation method of ferrite permanent magnetic material

A ferrite permanent magnet and formula technology, which is applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of inconvenient use of ferrite permanent magnet materials, low brittle magnetism, and inability to perform self-cleaning and anti-rust problems, to achieve good promotion and use value, improve the coercive force, and increase the effect of product compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

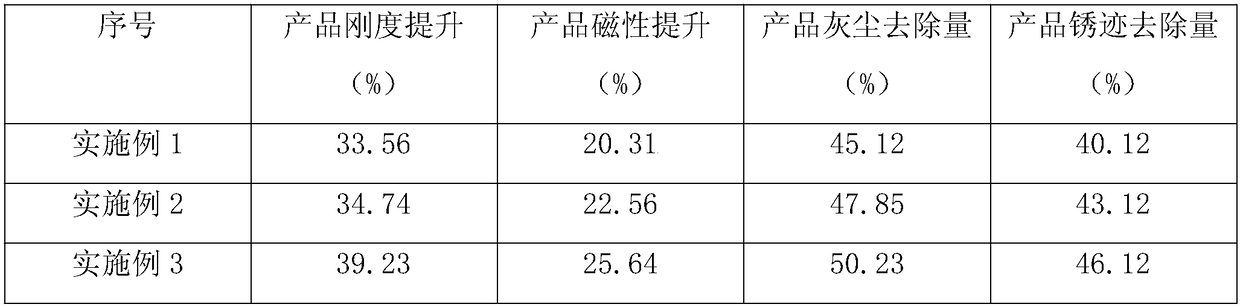

Examples

Embodiment 1

[0025] The invention provides a formula of ferrite permanent magnet material, which comprises the following components by weight percentage: iron red 60%, barium carbonate 10%, silicon dioxide 5%, calcium carbonate 3%, strontium sulfate 5%, titanium dioxide 1 %, rust remover 5%.

[0026] The configuration method is as follows:

[0027] Step 1: Mix the barium carbonate and iron red at a ratio of 1:5, stir for 10 minutes to make the barium carbonate and iron red evenly distributed, and pour it into a container bottle;

[0028] Step 2: Add silicon dioxide into the container bottle described in step 1, and stir for 5 minutes to make the silicon dioxide evenly distributed;

[0029] Step 3: heating the calcium carbonate at 1000° for 30 minutes, so that the calcium carbonate forms a solution;

[0030] Step 4: Cool the solution described in Step 3 to 26° to form a solid and stir it into particles;

[0031] Step 5: Add the particles described in step 4 into the container bottle desc...

Embodiment 2

[0038] The invention provides a formula of ferrite permanent magnet material, which comprises the following components in weight percent: iron red 70%, barium carbonate 12%, silicon dioxide 8%, calcium carbonate 5%, strontium sulfate 7%, titanium dioxide 17% %, rust remover 8%.

[0039] The configuration method is as follows:

[0040] Step 1: Mix the barium carbonate and iron red at a ratio of 1:5, stir for 10 minutes to make the barium carbonate and iron red evenly distributed, and pour it into a container bottle;

[0041] Step 2: Add silicon dioxide into the container bottle described in step 1, and stir for 5 minutes to make the silicon dioxide evenly distributed;

[0042] Step 3: heating the calcium carbonate at 1000° for 30 minutes, so that the calcium carbonate forms a solution;

[0043] Step 4: Cool the solution described in Step 3 to 26° to form a solid and stir it into particles;

[0044] Step 5: Add the particles described in step 4 into the container bottle descr...

Embodiment 3

[0051]The invention provides a formula of ferrite permanent magnet material, which comprises the following components in weight percent: iron red 70%, barium carbonate 16%, silicon dioxide 10%, calcium carbonate 8%, strontium sulfate 8%, titanium dioxide 15% %, rust remover 8%.

[0052] The configuration method is as follows:

[0053] Step 1: Mix the barium carbonate and iron red at a ratio of 1:5, stir for 10 minutes to make the barium carbonate and iron red evenly distributed, and pour it into a container bottle;

[0054] Step 2: Add silicon dioxide into the container bottle described in step 1, and stir for 5 minutes to make the silicon dioxide evenly distributed;

[0055] Step 3: heating the calcium carbonate at 1000° for 30 minutes, so that the calcium carbonate forms a solution;

[0056] Step 4: Cool the solution described in Step 3 to 26° to form a solid and stir it into particles;

[0057] Step 5: Add the particles described in step 4 into the container bottle descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com