Molting hormone extracting method

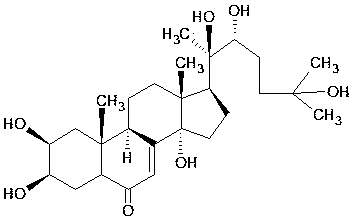

A technology of ecdysone and extract, which is applied in the direction of steroids and organic chemistry, can solve the problems of affecting the biological activity of ecdysone, increasing the processing cost of enterprises, and the long production period of column chromatography, so as to achieve short cycle and short extraction route , the effect of fast time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: this extracts the method for ecdysone from dew grass, concrete operations are as follows:

[0029] (1) Add 100kg of dew grass powder with ecdysterone content of 3.1% (water content 8%), add 300L methanol to the crushed product and soak for 4 hours, filter, filter residue soaked in 300L methanol for 4 hours, filter, and combine the two filtrates , concentrated under reduced pressure at 65°C to 1 / 5 of the original volume to obtain a yellow-green ecdysone extract;

[0030] (2) Put the ecdysone extract in a 100L container, add activated carbon and diatomaceous earth at a ratio of 100 g of decolorizing flocculant per L of ecdysone extract, the mass ratio of activated carbon to diatomite is 2:1, Stir and decolorize at 40°C for 4 hours, filter under reduced pressure, remove activated carbon and diatomaceous earth, and obtain a light yellow transparent methanol liquid; evaporate the methanol liquid on a rotary evaporator at 65°C under reduced pressure to obtain ye...

Embodiment 2

[0033] Embodiment 2: this extracts the method for ecdysone from dew grass, concrete operation is as follows:

[0034](1) Take 100kg of dew grass powder with ecdysterone content of 3.1% (water content 5%), add 400L methanol to the crushed product and soak for 3 hours, filter, soak the filter residue in 300L methanol for 3 hours, filter, and filter the filter residue with methanol again Soak, combine the filtrates for 3 times, and concentrate under reduced pressure at 60°C to 1 / 5 of the original volume to obtain a yellow-green ecdysone extract;

[0035] (2) Put the ecdysone extract in a container, add activated carbon and diatomite at a ratio of 80 g of decolorizing flocculant per L of ecdysone extract, the mass ratio of activated carbon to diatomite is 3:1, at 45 Stir and decolorize at ℃ for 3 hours, filter under reduced pressure, filter out activated carbon and diatomaceous earth, and obtain a light yellow transparent methanol liquid; evaporate the methanol liquid on a rotary ...

Embodiment 3

[0038] Embodiment 3: this extracts the method for ecdysone from dew grass, concrete operations are as follows:

[0039] (1) Put 100kg of dew grass powder with 3.1% ecdysterone content (water content 7%), add 350L methanol-acetone mixture (methanol and acetone by volume ratio 1:0.5) to the crushed product, soak for 3 hours, filter, The filter residue was once again soaked in 300L methanol-acetone mixture for 4 hours, filtered, and the two filtrates were combined, concentrated under reduced pressure at 65°C to 1 / 5 of the original volume to obtain a yellow-green ecdysone extract;

[0040] (2) Put the ecdysone extract in a 100L container, add activated carbon and diatomite at the ratio of 120 g of decolorizing flocculant per L of ecdysone extract, the mass ratio of activated carbon to diatomite is 5:1, Stir and decolorize at 50°C for 4 hours, filter under reduced pressure, remove activated carbon and diatomaceous earth, and obtain a light yellow transparent methanol liquid; evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com