Environment-friendly thermal insulation paint and preparation method thereof

A heat-insulating coating, an environmentally friendly technology, applied in the field of coatings, can solve the problems of poor environmental protection, poor heat insulation effect, etc., and achieve the effect of improving reflective heat insulation performance, film-forming performance, and promoting uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

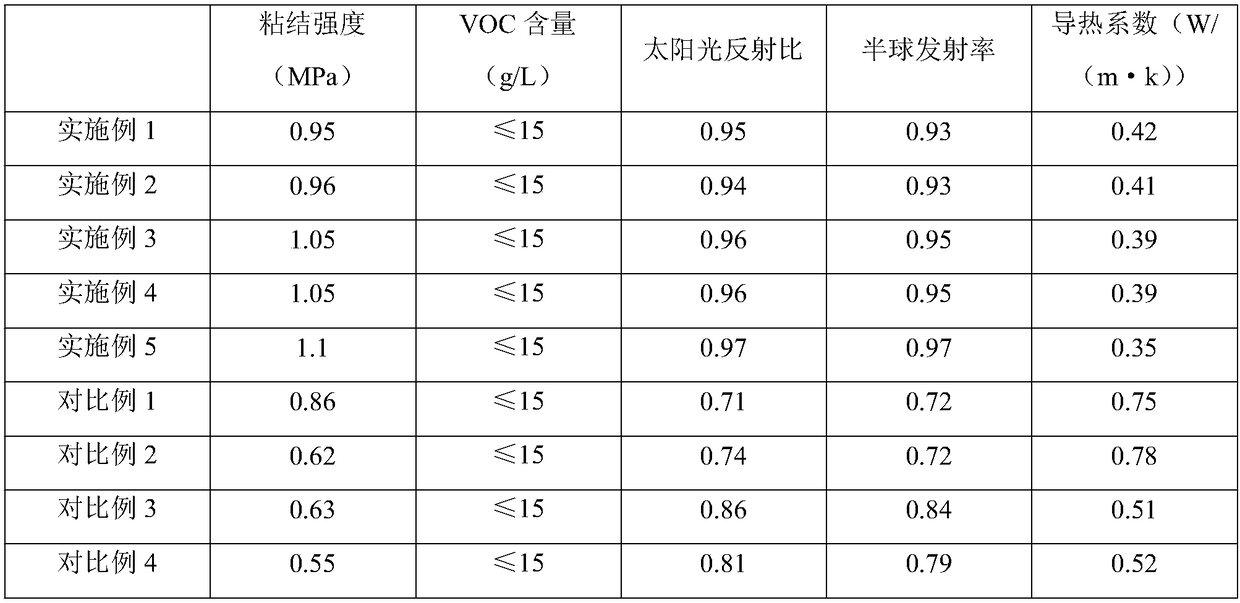

Examples

Embodiment 1

[0032] A preparation method of an environmentally friendly heat-insulating coating, comprising the following steps:

[0033] (1) Add dispersant, leveling agent, film-forming aid and silane coupling agent into deionized water, stir evenly to obtain the first mixture, and set aside;

[0034] (2) Add nano-lanthanum hexaboride, nano-chromium oxide, and nano-titanium dioxide into polyethylene glycol 200, then add cyclohexyl methacrylate-modified hydroxyacrylic resin, and ultrasonically disperse for 20 minutes to obtain the second mixture for later use ;

[0035] (3) Mix water-based polyurethane emulsion, water-based fluorocarbon emulsion resin, styrene-acrylate copolymer emulsion and bisphenol A polycarbonate evenly, stir at low speed to disperse, slowly add the second mixture obtained in step (2) while stirring, medium speed stirring and dispersing to obtain the third mixture;

[0036] (4) Pour the third mixture obtained in step (4) into the first mixture obtained in step (1), s...

Embodiment 2

[0047] A preparation method of an environmentally friendly heat-insulating coating, comprising the following steps:

[0048] (1) Add dispersant, leveling agent, film-forming aid and silane coupling agent into deionized water, stir evenly to obtain the first mixture, and set aside;

[0049] (2) Add nano-lanthanum hexaboride, nano-chromium oxide, and nano-titanium dioxide into polyethylene glycol 200, then add cyclohexyl methacrylate modified hydroxyacrylic resin, and ultrasonically disperse for 30 minutes to obtain the second mixture for later use ;

[0050] (3) Mix water-based polyurethane emulsion, water-based fluorocarbon emulsion resin, styrene-acrylate copolymer emulsion and bisphenol A polycarbonate evenly, stir at low speed to disperse, slowly add the second mixture obtained in step (2) while stirring, medium speed stirring and dispersing to obtain the third mixture;

[0051](4) Pour the third mixture obtained in step (4) into the first mixture obtained in step (1), st...

Embodiment 3

[0062] A preparation method of an environmentally friendly heat-insulating coating, comprising the following steps:

[0063] (1) Add dispersant, leveling agent, film-forming aid and silane coupling agent into deionized water, stir evenly to obtain the first mixture, and set aside;

[0064] (2) Add nano-lanthanum hexaboride, nano-chromium oxide, and nano-titanium dioxide into polyethylene glycol 200, then add cyclohexyl methacrylate-modified hydroxyacrylic resin, and ultrasonically disperse for 20 minutes to obtain the second mixture for later use ;

[0065] (3) Mix water-based polyurethane emulsion, water-based fluorocarbon emulsion resin, styrene-acrylate copolymer emulsion and bisphenol A polycarbonate evenly, stir at low speed to disperse, slowly add the second mixture obtained in step (2) while stirring, medium speed stirring and dispersing to obtain the third mixture;

[0066] (4) Pour the third mixture obtained in step (4) into the first mixture obtained in step (1), s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com