Biomass oil composition and preparation method and application

A technology of biomass oil and composition, which is applied in the preparation of liquid hydrocarbon mixtures, biofuels, biological raw materials, etc., can solve the problems of complex and cumbersome biomass pretreatment process, high coke content, etc., to optimize hydrolysis effect, increase production, The effect of simplifying the pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a composition for biomass oil, the method comprising mixing biomass with liquid oil to obtain a mixed liquid; wherein, based on the weight of biomass, the biomass has a water content of 3-18wt% , preferably, the biomass has a moisture content of 5-10 wt%. Preferably, based on 100 parts by weight of the total weight of the composition for biomass oil, the biomass accounts for 10-40 parts by weight, preferably 30-40 parts by weight, and the biomass is mixed with the liquid oil.

[0036] Before the biomass is mixed with liquid oil, the biomass is subjected to a pretreatment process, which is to dry the biomass so that the water content in the biomass meets the above requirements, and then crush the dried biomass to obtain the volume particle size Distribute the solid biomass particles within the range of 1 μm-5000 μm, preferably 20 μm-200 μm, and finally carry out ash removal treatment on the solid biomass particle...

Embodiment 1

[0042] Drying the wheat straw so that the water content in the wheat straw is 18wt%, and then pulverizing the dried wheat straw to obtain wheat straw particles with a volume particle size distribution range of 20 μm-200 μm, and finally deashing the wheat straw particles deal with.

[0043] According to 100 parts by weight of the total weight of the composition for biomass oil, 5 parts by weight of a hydrocracking catalyst (commercially available amorphous iron oxyhydroxide) is mixed with the wheat straw particles after deashing, and at the same time, 0.4 parts by weight of sulfur is added as a vulcanizing agent. Then, the obtained mixture is mixed with commercially available peanut oil based on 100 parts by weight of the total weight of the composition for biomass oil, and wheat straw particles account for 35 parts by weight, and the mixture is mixed with peanut oil to obtain a mixed slurry.

Embodiment 2-5

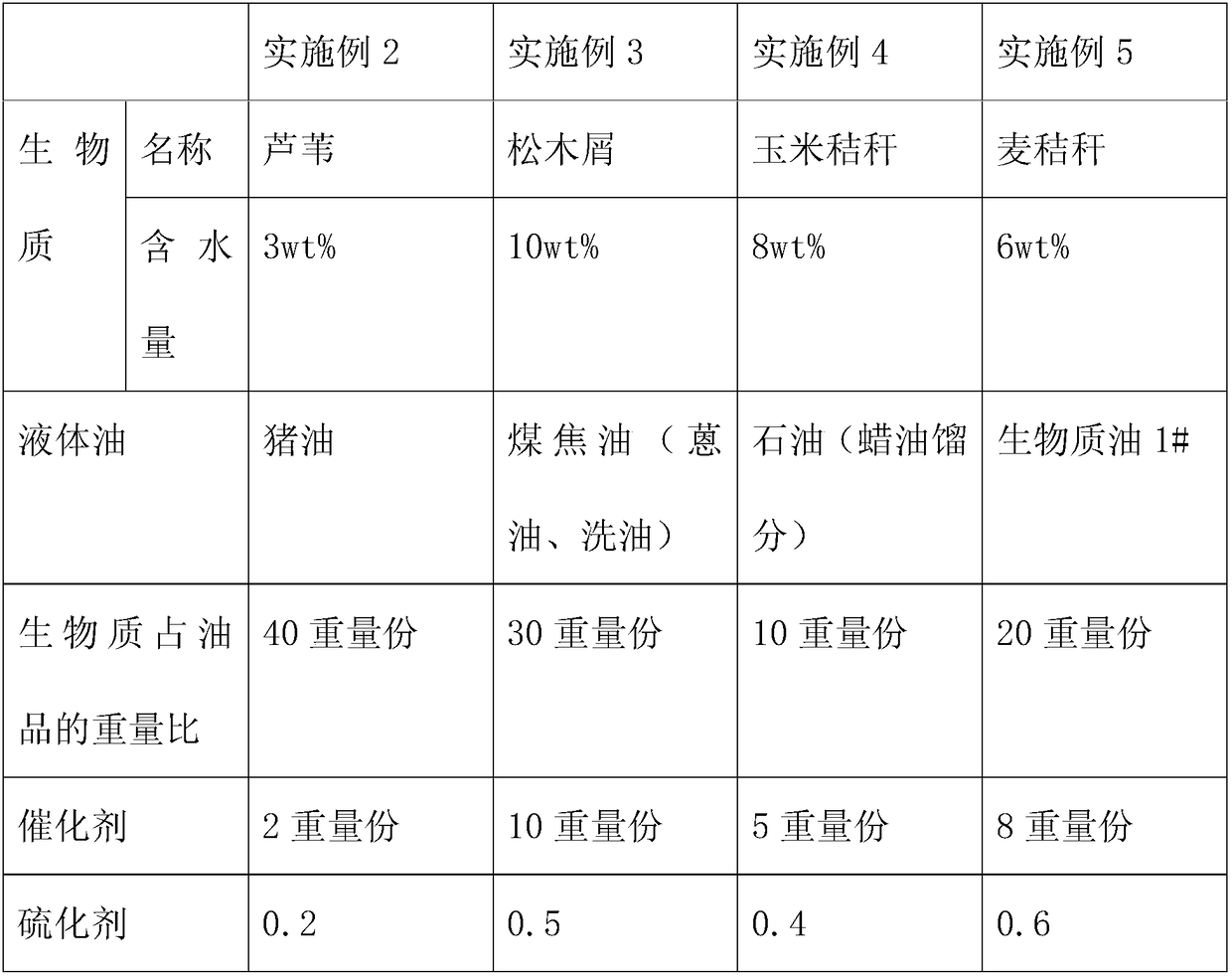

[0045] Embodiment 2-5 has adopted the processing step identical with embodiment 1, and difference is as shown in table 1:

[0046] Table 1

[0047]

[0048] It should be noted that the biomass oil used in Example 5 is the biomass oil 4# obtained in the subsequent hydrohydrolysis of Example 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com