Cleaning agent for printed circuit board and preparation method

A printed circuit board and cleaning agent technology, which is applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., can solve the problem of corrosion on the surface of copper plates, high defective rate, and the quality of circuit boards produced. impact and other issues, to achieve the effect of increasing the yield rate, improving the cleanliness of washing, and ensuring normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method for a printed circuit board cleaning agent, comprising the following steps:

[0042] 1) Add the emulsifier into deionized water and stir until completely dissolved;

[0043] 2) Add a solubilizer to the solution obtained in step 1), and stir until completely dissolved;

[0044] 3) Add defoamer and stir until completely dissolved;

[0045] 4) Add the pH regulator and stir until completely dissolved;

[0046] 5) Add surfactant and mix to obtain finished product.

[0047] In step 1), the temperature of the solution is controlled at 10-30° C. during the stirring process.

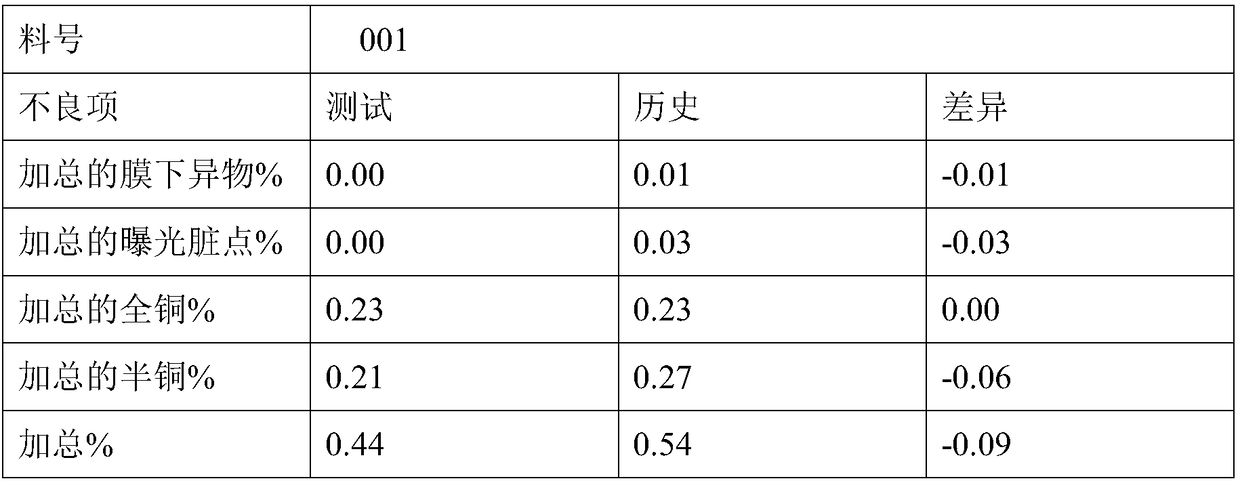

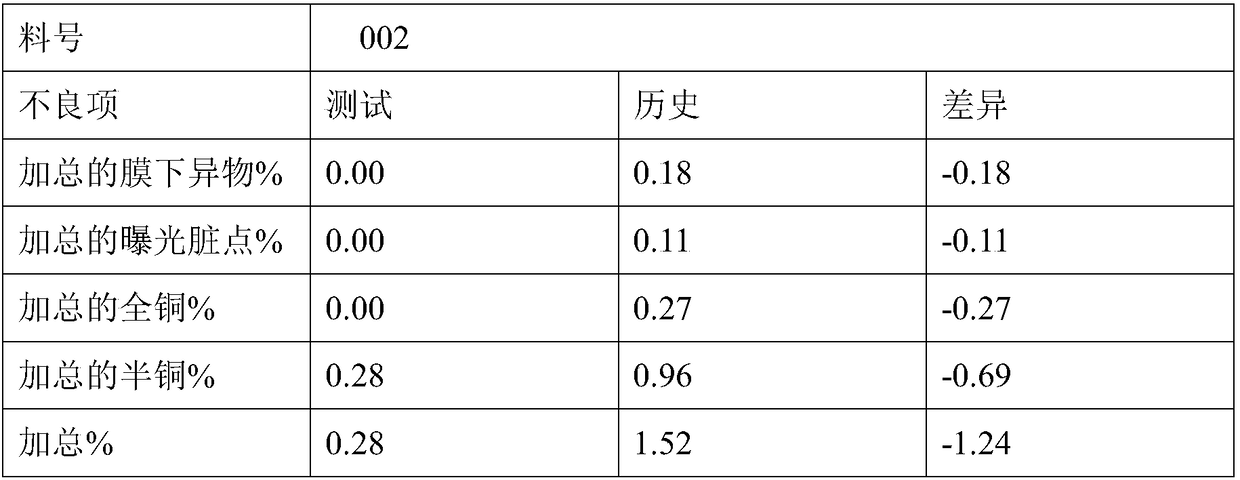

[0048] Using the cleaning agent of the present invention, the dosage and cleaning effect of the cleaning agent are significantly higher than those of conventional cleaning agents, and the residual substances after dry film development can be removed efficiently, the normal production of the printed circuit board process can be ensured, and the yield rate of printed circuit boards ca...

Embodiment 1

[0057] Emulsifier: 5kg;

[0058] Solubilizer: 1kg;

[0059] Defoamer: 0.1kg;

[0060] pH regulator: 1kg;

[0061] Surfactant: 3kg;

[0062] The balance is deionized water: 89.9kg;

[0063] Configure a cleaning agent with a total mass of 100kg, choose TX-10 as emulsifier; fatty alcohol polyoxyethylene-polyoxypropylene ether as solubilizer; choose polyether type GP defoamer as defoamer; choose sodium carbonate as pH regulator; surfactant Choose Sodium Lauryl Sulfate.

[0064] Preparation method: first mix emulsifier TX-10 with deionized water and stir to dissolve, then add fatty alcohol polyoxyethylene-polyoxypropylene ether, polyether type GP defoamer, sodium carbonate, sodium dodecylsulfonate in sequence , Stir under normal temperature and pressure to make it all dissolve. Obtain a colorless and transparent liquid cleaning agent, ready to use.

[0065] When in use, add 3% cleaning agent to the water, the cleaning temperature is 30±2°C, and the cleaning time is 20 minute...

Embodiment 2

[0069] Emulsifier: 5kg;

[0070] Solubilizer: 1kg;

[0071] Defoamer: 0.1kg;

[0072] pH regulator: 1kg;

[0073] Surfactant: 3kg;

[0074] The balance is deionized water: 89.9kg;

[0075] Configure a cleaning agent with a total mass of 100kg, choose NP-10 as emulsifier; fatty alcohol polyoxyethylene-polyoxypropylene ether as solubilizer; choose polyether GP defoamer as defoamer; choose sodium carbonate as pH regulator; surfactant Choose Sodium Lauryl Sulfate.

[0076] Preparation method: firstly mix emulsifier NP-10 with deionized water and stir to dissolve, then add solubilizer fatty alcohol polyoxyethylene-polyoxypropylene ether in sequence, defoamer choose polyether type, pH adjuster choose sodium carbonate, surface The active agent is sodium dodecylsulfonate, which is stirred under normal temperature and pressure to dissolve it completely. Obtain a colorless and transparent liquid cleaning agent, ready to use.

[0077] When in use, add 3% cleaning agent to the water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com