Bamboo fiber plate for internal wall thermal insulation and preparation method thereof

A bamboo fiber and interior wall technology, which is applied in the field of boards, can solve the problems of heat storage, heat preservation, sound insulation, antibacterial, deodorant, and mite removal effects, reduced bamboo fiber consumption, and insufficient performance such as compression resistance and bending fracture resistance. Good effect, enhanced bonding performance, enhanced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

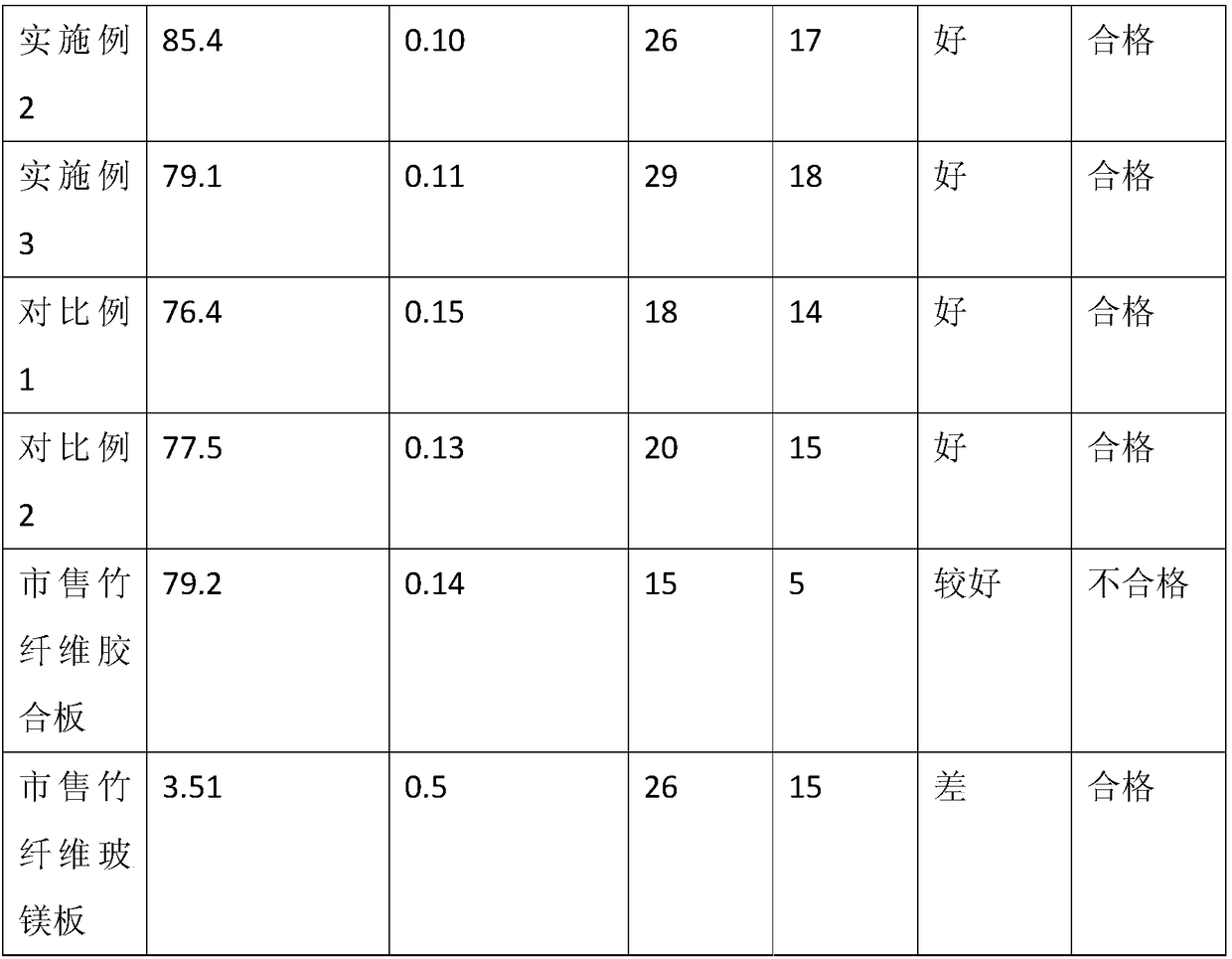

Examples

Embodiment 1

[0024] The production process of bamboo fiber is as follows: firstly cut the bamboo into long strips along the growth direction of bamboo, and then carbonize with steam at 200°C for 4.5 hours under the pressure of 3.2MPa to reduce the sugar content of the bamboo strips to 4%. , the bamboo fiber is reduced to 80%, and the water content reaches 30%, to obtain carbonized bamboo strips, and then the carbonized bamboo strips are mechanically defibrillated to obtain preliminary bamboo fibers, and the preliminary bamboo fibers are dried at 50°C to control their moisture content at 3%. , get bamboo fiber.

Embodiment 2

[0026] The preparation method of modified basalt fiber is: first prepare sizing agent (the mass concentration of each component in the sizing agent is epoxy resin 5%, polyvinyl alkyl ester 0.3%, polyoxyalkylene stearate 0.3%, Fatty amide acetate 0.5%, glycidoxy silane 0.4%) preparation method is: take described epoxy resin, polyvinyl alkyl ester, polyoxyalkylene stearate, fatty amide acetate, cyclic After the oxypropoxysilane, it is added into deionized water in turn, stirred and dispersed until uniform, and the sizing agent is obtained; then the basalt fiber is soaked in the sizing agent so that the sizing agent is coated on the surface of the basalt fiber, and then The basalt fiber coated with the sizing agent is baked and sintered at a high temperature of 200-250° C. to melt the epoxy resin and form a film on the surface of the fiber to obtain the modified basalt fiber.

Embodiment 3

[0028] A kind of bamboo fiberboard for interior wall thermal insulation, comprises the raw material of following weight part:: the bamboo fiber that embodiment 1 makes: 65 parts; The modified basalt fiber that embodiment 2 makes: 20 parts; 7 parts of epoxy resins; Polyurethane 4 parts of resin; diluent: 6 parts of polypropylene alcohol diglycidyl ether; curing agent: 6 parts of m-phenylenediamine; 0.05 part of paraben.

[0029] Its preparation process is as follows:

[0030] Step 1. Weigh each raw material according to the above weight, mix the bamboo fiber and the modified basalt fiber evenly, then add the epoxy resin and polyurethane resin to the diluent, fully stir and disperse evenly, and then add it to the evenly mixed bamboo fiber Fiber and modified basalt fiber are added to epoxy resin and fully stirred to make a premix;

[0031] Step 2. Add the premixed material that has been fully stirred evenly into the curing agent, and then fully stir it as a material preparation;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com