Cement-stabilized base material and design method thereof

A base material and cement stabilization technology, applied in the field of civil engineering, can solve the problems of insufficient utilization, large differences in physical and mechanical properties of coal gangue, and high working intensity, to meet the needs of sustainable development, superior physical and mechanical properties, The effect of reducing road construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

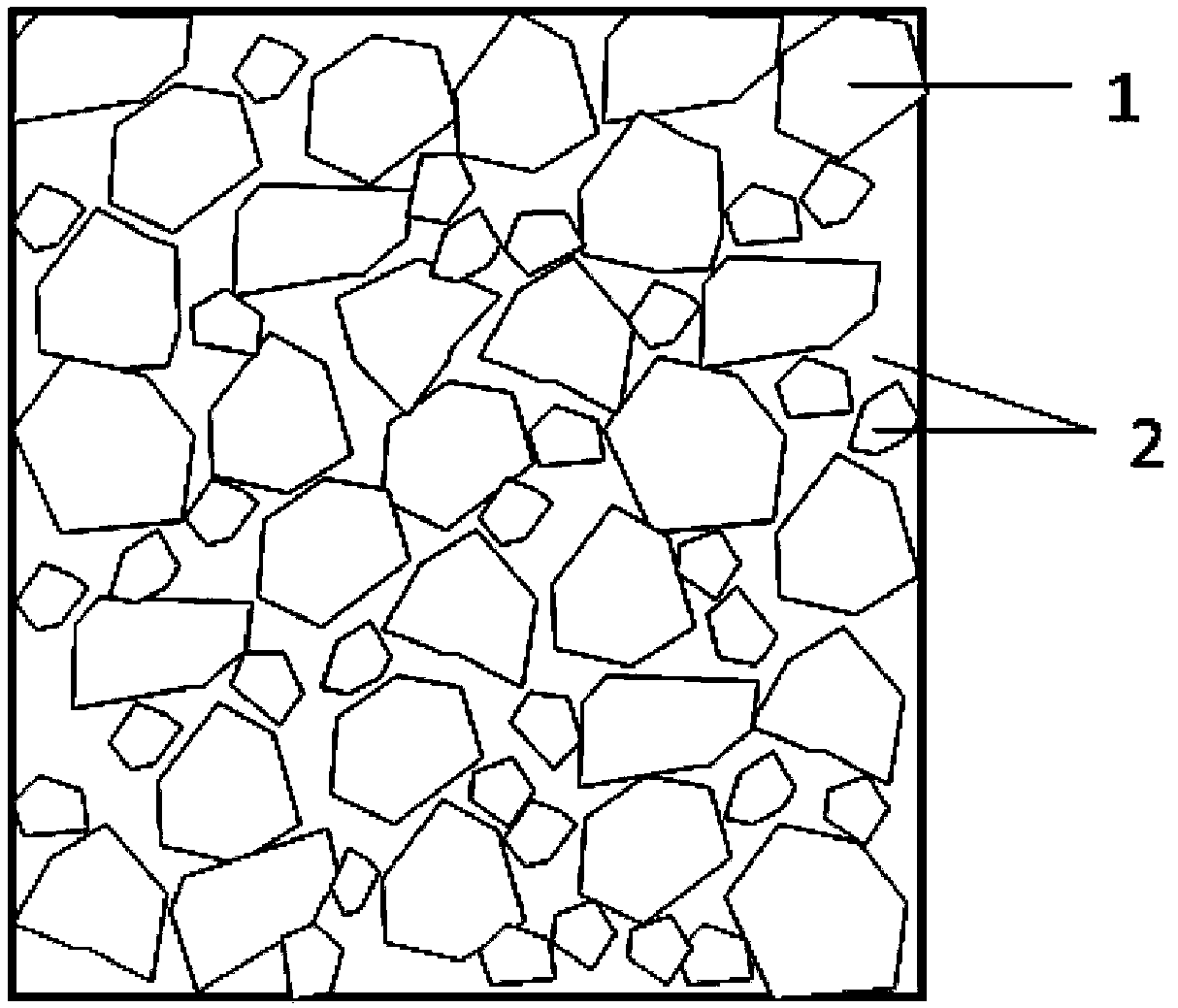

[0045] A cement-stabilized base material, which uses coal gangue fines to replace part of aggregates, and consists of the following components by weight:

[0046] Coal gangue fine material 40.8%;

[0047] Limestone aggregate 49.8%;

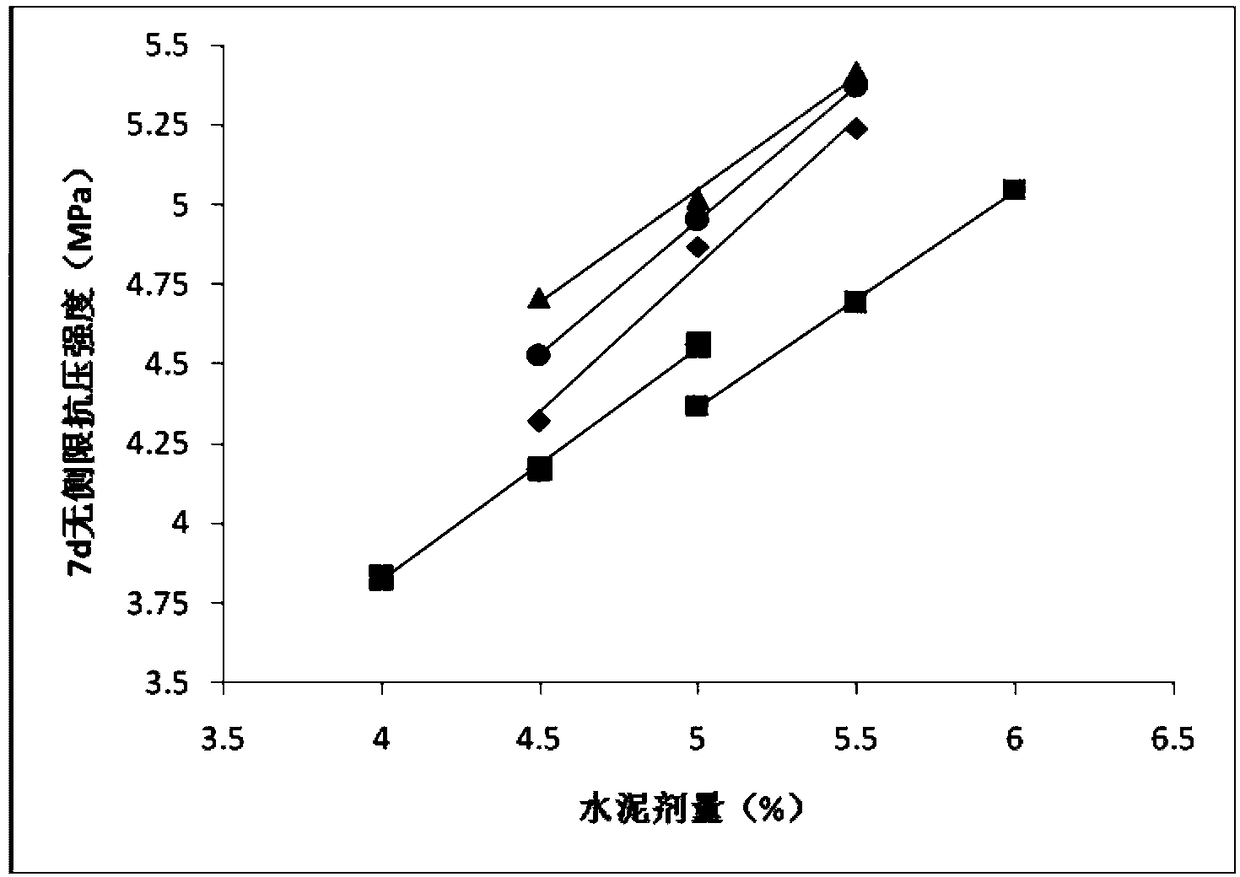

[0048] Cement 5.0%;

[0049] The balance is water.

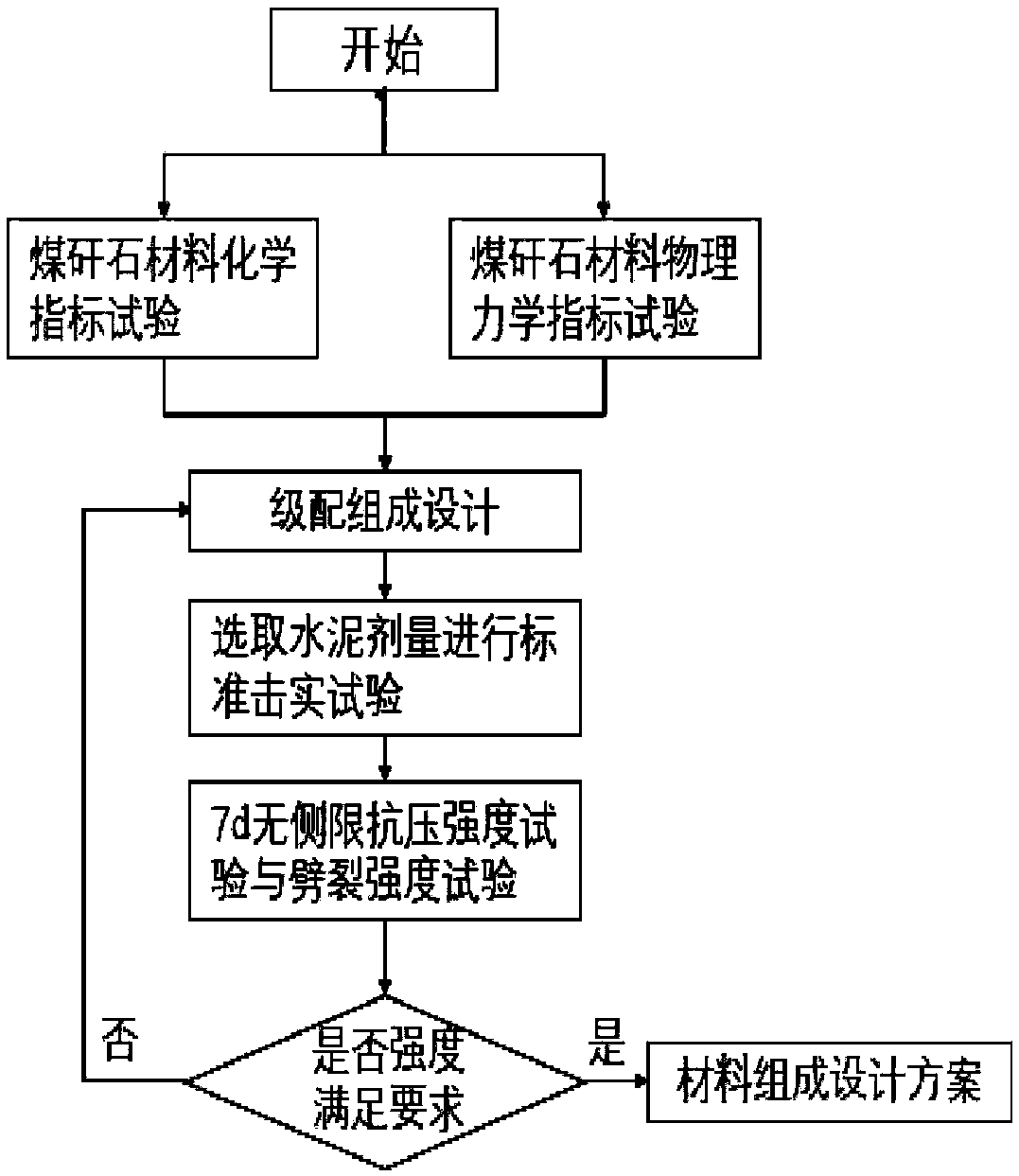

[0050] A novel cement-stabilized base material and a design method for substituting part of aggregates with coal gangue fine materials, comprising the following steps:

[0051]1) Carry out basic chemical and physical and mechanical index tests on coal gangue samples, and confirm that the coal gangue used this time belongs to carbonaceous shale coal gangue. The mineral composition is mainly quartz and feldspar, and the chemical composition is SiO 2 and Al 2 o 3 Mainly, the content of active chemical components in pozzolan ash reaches 83.7%, which has high potential activity, and the loss on ignition is 16.4%. Its apparent density is close to that of rock, its water absorption rate is small,...

example 2

[0065] A cement-stabilized base material, which uses coal gangue fines to replace part of aggregates, and consists of the following components by weight:

[0066] Coal gangue fine material 58.4%;

[0067] Limestone aggregate 31.5%;

[0068] Cement 5.4%;

[0069] The balance is water.

[0070] in

[0071] A novel cement-stabilized base material and a design method for substituting part of aggregates with coal gangue fine materials, comprising the following steps:

[0072] 1) The coal gangue used this time belongs to carbonaceous shale coal gangue, the mineral composition is mainly quartz and feldspar, and the chemical composition is SiO 2 and Al 2 o 3 Mainly, the content of active chemical components in pozzolan ash reaches 83.7%, which has high potential activity, and the loss on ignition is 16.4%. Its apparent density is close to that of rock, its water absorption rate is small, its compactness is good, its crushing value reaches 31.3%, its wear rate is high, its Calif...

example 3

[0086] A cement-stabilized base material, which uses coal gangue fines to replace part of aggregates, and consists of the following components by weight:

[0087] Coal gangue fine material 31.5%;

[0088] Limestone aggregate 58.6%;

[0089] Cement 5.0%;

[0090] The balance is water.

[0091] A novel cement-stabilized base material and a design method for substituting part of aggregates with coal gangue fine materials, comprising the following steps:

[0092] 1) The coal gangue used this time belongs to carbonaceous shale coal gangue, the mineral composition is mainly quartz and feldspar, and the chemical composition is SiO 2 and Al 2 o 3 Mainly, the content of active chemical components in pozzolan ash reaches 81.3%, which has high potential activity, and the loss on ignition is 15.4%. Its apparent density is close to that of rock, its water absorption rate is small, its compactness is good, its crushing value reaches 32.1%, its wear rate is high, its California bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com