A kind of wall coating and preparation method thereof

A coating and raw material technology, applied in the field of wall coating and its preparation, can solve problems affecting the environment and human health, and achieve good dispersibility, anti-corrosion, mildew-proof and waterproof functions, good viscosity stability, and enhanced water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

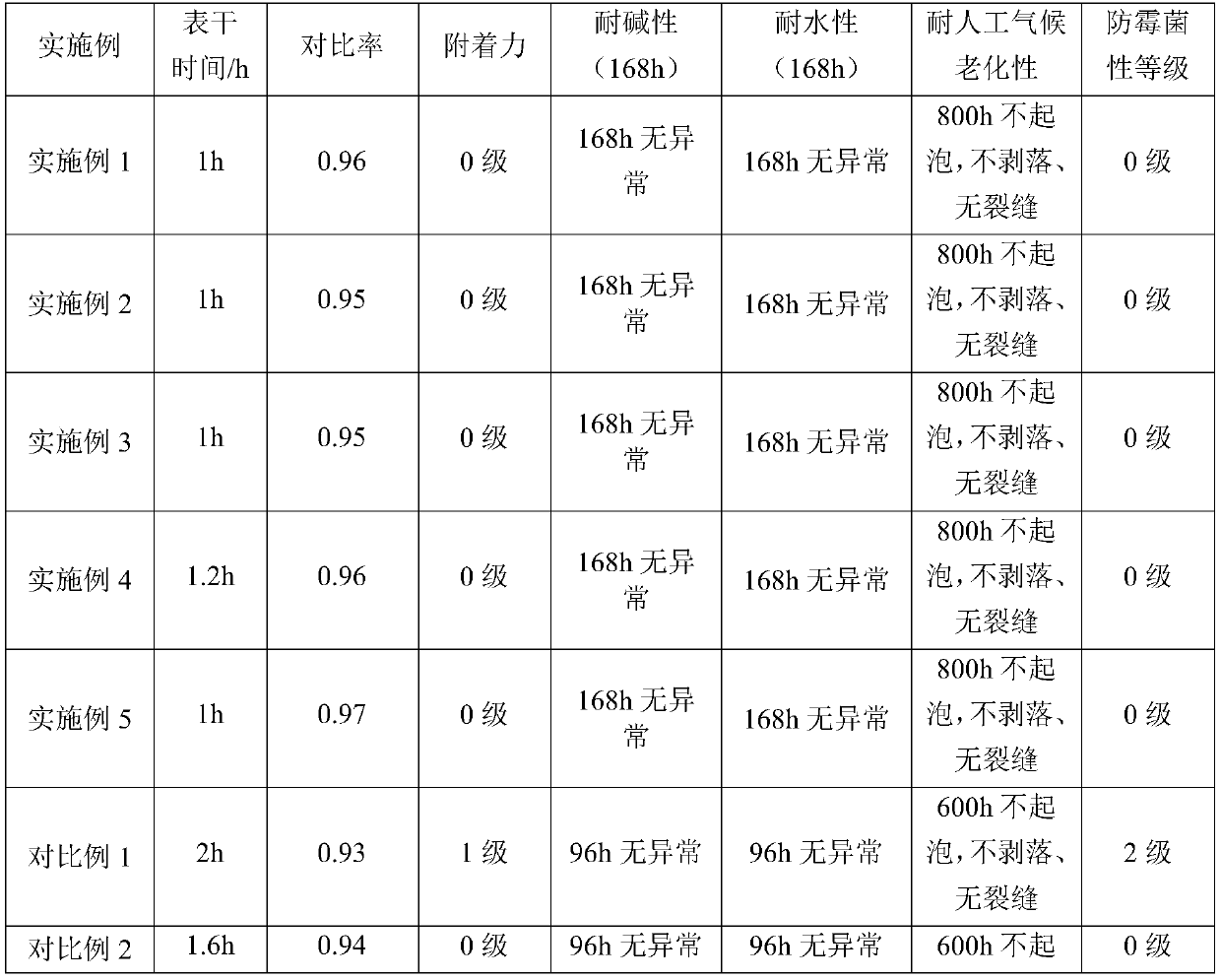

Examples

Embodiment 1

[0057] The embodiment of the present invention provides a kind of preparation method of wall coating, comprises the following steps:

[0058] (1) take by weighing the deionized water of 20~40 parts by weight, the styrene-acrylic resin of 20~40 parts by weight, the hydroxyethyl cellulose of 0.3~0.8 parts by weight, the vinylbisstearamide of 1~5 parts by weight, 50-70 parts by weight of talcum powder and 10-15 parts by weight of rutile titanium dioxide are mixed and stirred for 3-10 minutes under the condition of 100-500 r / min to prepare the base material.

[0059] (2) Weigh 80 to 95 parts by weight of deionized water, 0.2 to 0.6 parts by weight of preservative B, 3 to 5 parts by weight of sodium pyrophosphate, and 3 to 5 parts by weight of magnesium aluminum silicate powder. Stir for 3-10 minutes under the condition of 100-500 r / min to prepare the protective glue.

[0060] (3) Under the condition of 100-200r / min, 30-50 parts by weight of deionized water, 1-5 parts by weight of...

Embodiment 2

[0085] The embodiment of the present invention provides a kind of preparation method of wall coating, comprises the following steps:

[0086] (1) take by weighing the deionized water of 25 parts by weight, the styrene-acrylic resin of 25 parts by weight, the hydroxyethyl cellulose of 0.5 parts by weight, the vinylbisstearamide of 2 parts by weight, the talcum powder of 60 parts by weight, 12 For the rutile titanium dioxide in parts by weight, the above-mentioned raw materials were mixed and stirred for 5 minutes under the condition of 200 r / min to prepare the base material.

[0087] (2) Weigh 85 parts by weight of deionized water, 0.4 parts by weight of preservative B, 4 parts by weight of sodium pyrophosphate, and 4 parts by weight of magnesium aluminum silicate powder, and stir the above-mentioned raw materials under the condition of 300r / min 7min to make protective glue.

[0088] (3) under the condition of 150r / min, the deionized water of 40 parts by weight, the carrageena...

Embodiment 3

[0092] The embodiment of the present invention provides a kind of preparation method of wall coating, comprises the following steps:

[0093] (1) take by weighing the deionized water of 30 parts by weight, the styrene-acrylic resin of 30 parts by weight, the hydroxyethyl cellulose of 0.6 parts by weight, the vinylbisstearamide of 3 parts by weight, the talcum powder of 60 parts by weight, 12 For the rutile titanium dioxide in parts by weight, the above-mentioned raw materials were mixed and stirred for 5 minutes under the condition of 200 r / min to prepare the base material.

[0094] (2) Weigh 90 parts by weight of deionized water, 0.45 parts by weight of preservative B, 4.5 parts by weight of sodium pyrophosphate, and 4.5 parts by weight of magnesium aluminum silicate powder, and stir the above-mentioned raw materials under the condition of 250r / min 8min to make protective glue.

[0095] (3) Under the condition of 150r / min, the deionized water of 40 parts by weight, the carra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com