Thermoplastic PI (polyimide) hot melt adhesive film and preparation method thereof

A thermal and thermoplastic technology of polyimide, applied in the direction of adhesives, etc., can solve the problems of poor bonding performance of polyimide film, high price of monomer raw materials, high production cost, etc., and achieve easy operation and low water absorption , the effect of reducing regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

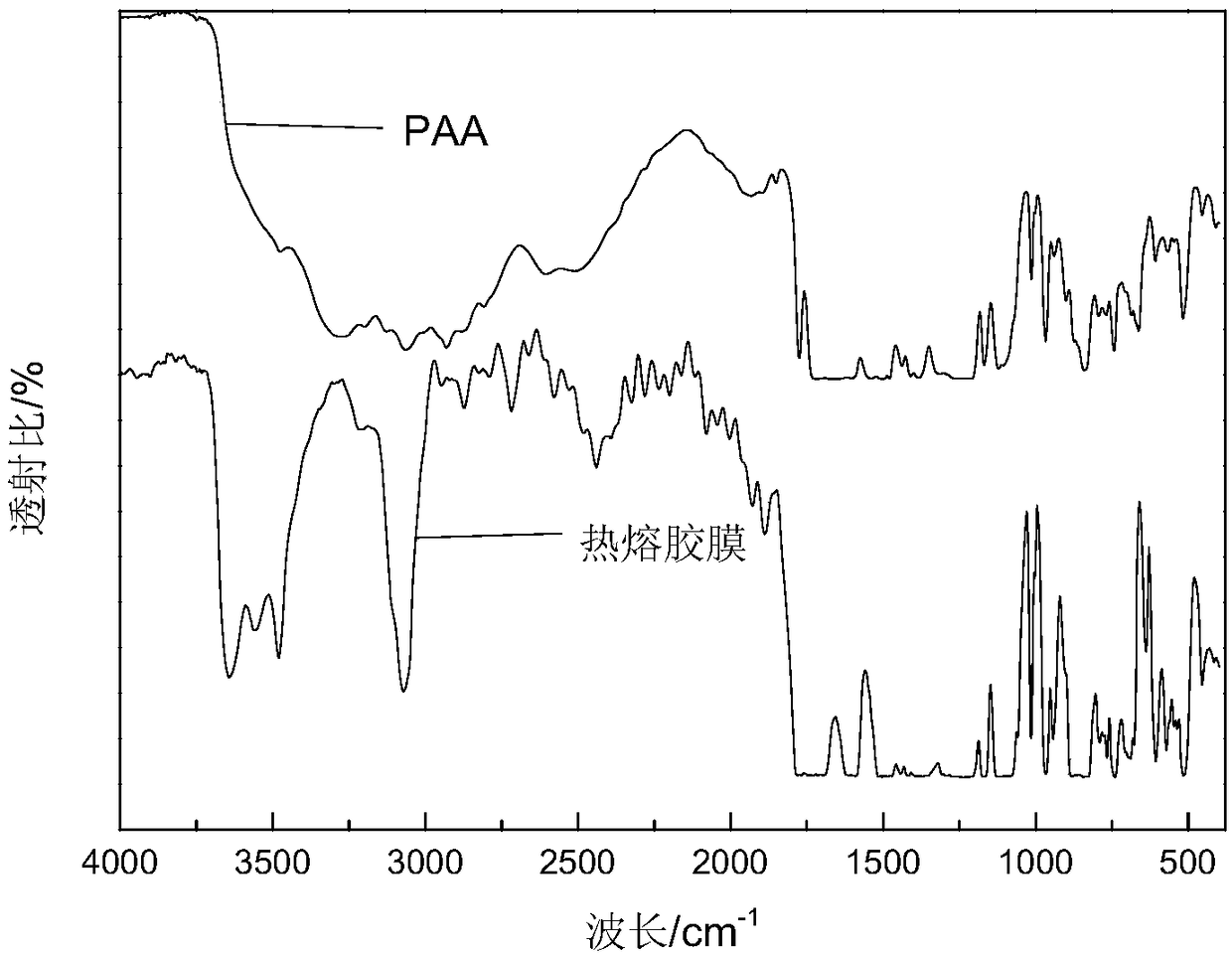

Image

Examples

Embodiment 1

[0029] The ambient humidity was controlled at 40%. In a 500mL three-necked flask, nitrogen was introduced from one of the flasks, 90ml of DMF was added from the other, and then 2.788g of ODA and 4.056g of TPER were added. Mechanical stirring was carried out at 0°C with a rotation speed of 150r / min, after stirring for 15 minutes, 1.633gα-BPDA and 6.533g BPDA were added at one time, the solution became cloudy, after stirring for 1 hour, the solution became clear again, and 16mgα-BPDA and 65mg BPDA were added. Keep stirring in a low-temperature ice bath and nitrogen atmosphere, and stir for 6 h to obtain a PAA solution.

[0030] Select a dry and clean glass plate, place it on the flat plate of the applicator, apply the prepared PAA solution on the surface of the glass plate, scrape the liquid surface with a scraper, and then put it in a circulating oven to dry at 100°C, evaporate and remove the solvent for 10 minutes . After the solvent evaporates, put the glass plate into a va...

Embodiment 2

[0033] The preparation method of Example 2 is basically the same as that of Example 1, except that DMF is replaced by DMAc to obtain polyimide hot melt adhesive film J-2, and the copper clad laminate prepared therefrom is numbered C-2.

Embodiment 3

[0035] The ambient humidity was controlled at 40%. In a 500mL three-necked flask, nitrogen was introduced from one of the flasks, 90ml of DMF was added from the other, and then 2.788g of ODA and 4.056g of TPER were added. Mechanical stirring was carried out at 5°C with a rotation speed of 150r / min, after stirring for 15 minutes, add 4.083gα-BPDA and 4.083g BPDA at one time, the solution becomes cloudy, after stirring for 1 hour, the solution becomes clear again, and then add 40mgα-BPDA and 40mg BPDA. Keep stirring in a low-temperature ice bath and nitrogen atmosphere, and stir for 6 h to obtain a PAA solution.

[0036] Select a dry and clean glass plate, place it on the flat plate of the applicator, apply the prepared PAA solution on the surface of the glass plate, scrape the liquid surface with a scraper, then put it in a circulating oven to dry at 80°C, evaporate and remove the solvent for 10 minutes . After the solvent evaporates, put the glass plate into a vacuum oven, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com