Washing machine slot cleanser and preparation method and application thereof

A washing machine tank and cleaning agent technology, applied in the field of cleaning products, can solve the problems of secondary pollution and unsatisfactory cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

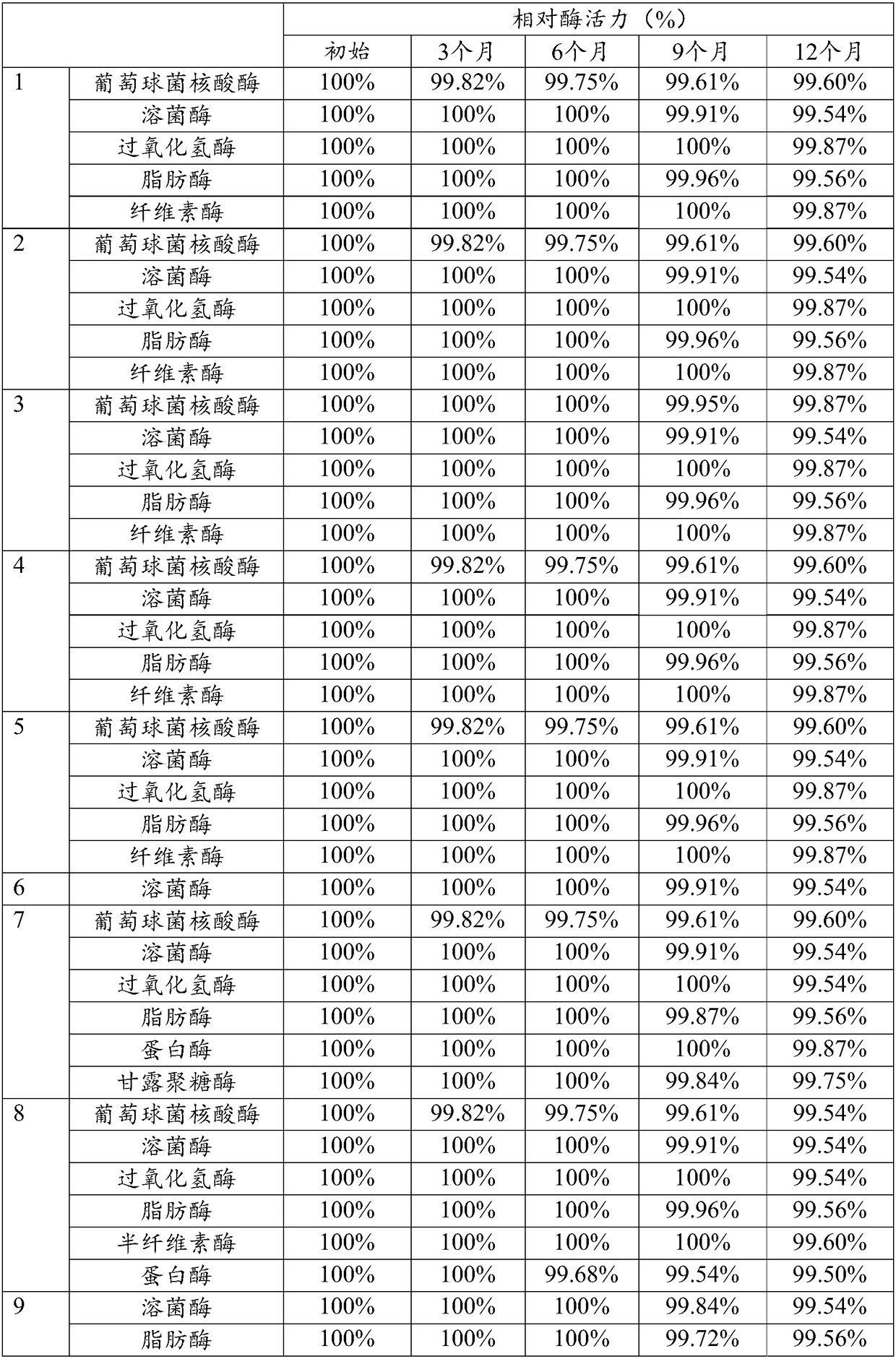

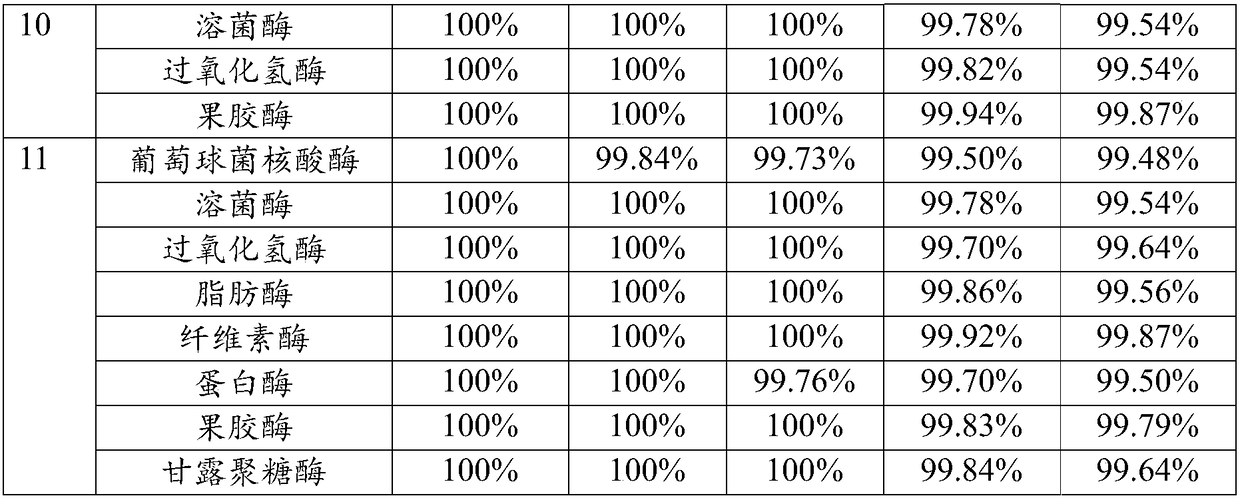

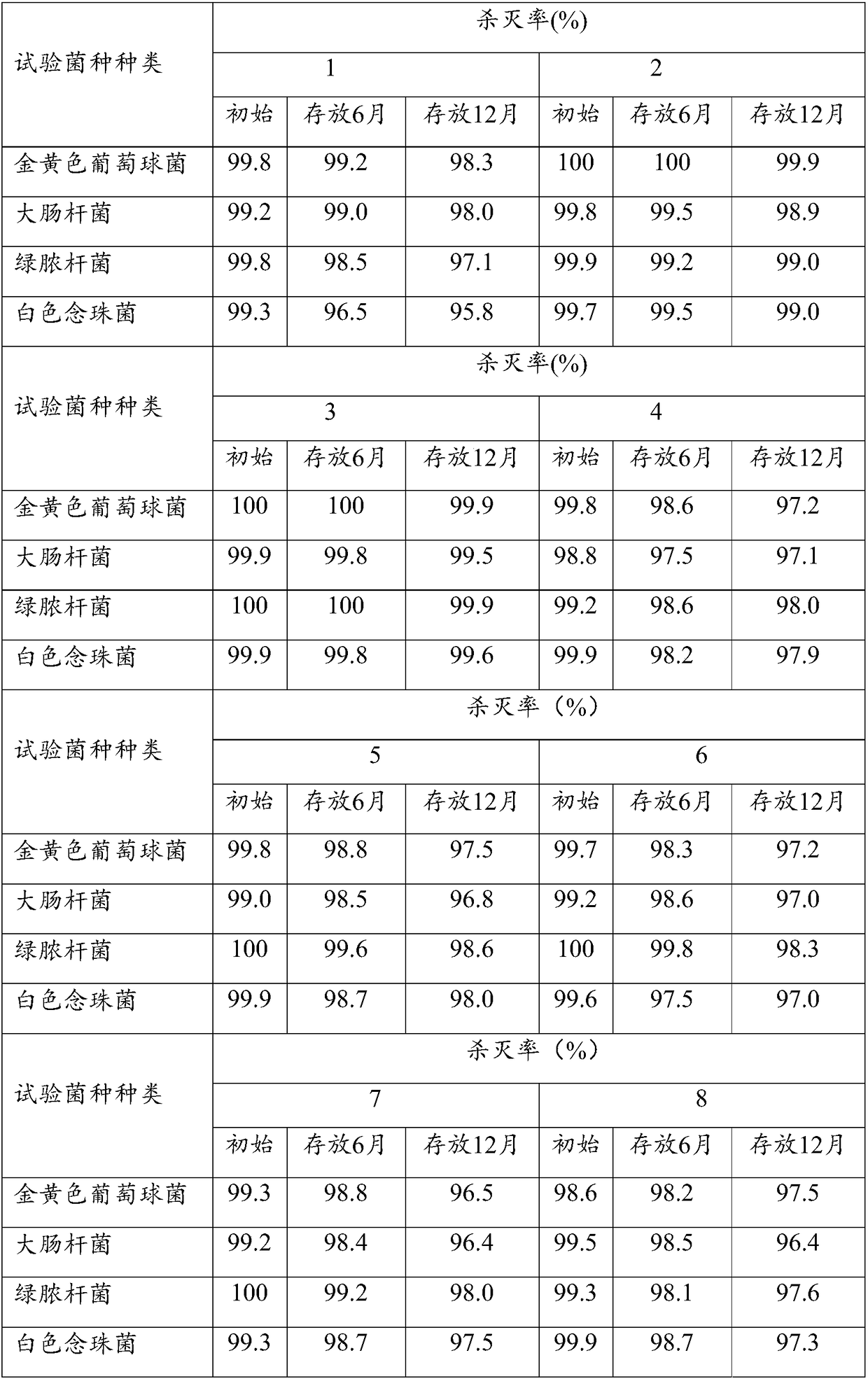

Examples

Embodiment 1

[0069] A kind of formula of washing machine tank cleaning agent is as follows: by weight, comprises following component: anionic surfactant (3 parts of sodium lauryl sulfate); Alkaline inorganic cleaning agent (26.8 parts of sodium carbonate); Builder ( 11 parts of sodium bicarbonate); enzyme preparation (0.3 part of lipase, 0.3 part of cellulase, 0.3 part of staphylococcal nuclease, 0.3 part of catalase, 0.3 part of lysozyme), 1.5 parts in total; enzyme stabilizer (borax 0.2 parts, 0.2 parts of succinic acid, 0.1 parts of sodium thiosulfate), a total of 0.5 parts; anti-fouling redeposition agent (0.2 parts of sodium carboxymethylcellulose); oxidation bleaching agent (50 parts of sodium percarbonate); metal corrosion inhibitor Protective agent (7 parts of sodium metasilicate pentahydrate).

[0070] In an embodiment of the present invention, the preparation method of washing machine tank cleaner comprises the following steps:

[0071] Step 1: Weigh each component according to ...

Embodiment 2

[0076] A kind of formula of washing machine tank cleaning agent is as follows: by weight, comprises following component: anionic surfactant (2 parts of sodium lauryl sulfate); Alkaline inorganic cleaning agent (25.2 parts of sodium carbonate); Builder ( 12 parts of sodium bicarbonate); enzyme preparation (0.5 part of lipase, 0.8 part of cellulase, 0.3 part of staphylococcal nuclease, 0.5 part of catalase, 0.4 part of lysozyme), 2.5 parts in total; enzyme stabilizer (borax 0.4 parts, 0.4 parts of succinic acid, 0.2 parts of sodium thiosulfate), 1 part in total; anti-fouling redeposition agent (sodium carboxymethylcellulose 0.3 parts); oxidative bleaching agent (sodium percarbonate 50 parts); metal corrosion inhibitor Protective agent (7 parts of sodium metasilicate pentahydrate).

[0077] In the embodiment of the present invention, the preparation method of washing machine tank cleaner is the same as embodiment 1.

Embodiment 3

[0079] A kind of formula of washing machine tank cleaning agent is as follows: by weight, comprises following component: anionic surfactant (3 parts of sodium lauryl sulfate); Alkaline inorganic cleaning agent (sodium carbonate 27.4 parts); Builder ( 10 parts of sodium bicarbonate); enzyme preparation (0.5 part of lipase, 0.5 part of cellulase, 0.5 part of staphylococcal nuclease, 0.5 part of catalase, 0.5 part of lysozyme), 2.5 parts in total; enzyme stabilizer (borax 0.3 parts, 0.2 parts of succinic acid, 0.3 parts of sodium thiosulfate), a total of 0.8 parts; anti-fouling redeposition agent (0.3 parts of sodium carboxymethylcellulose); oxidation bleaching agent (50 parts of sodium percarbonate); metal corrosion inhibitor Protective agent (6 parts of sodium metasilicate pentahydrate).

[0080] In the embodiment of the present invention, the preparation method of washing machine tank cleaner is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decontamination rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com