Preparation method of adsorbing material for 1,2-cyclohexane diisononyl phthalate

A technology of diisononyl cyclohexanedicarboxylate and adsorption materials, applied in the field of purification of diisononyl cyclohexanedicarboxylate, which can solve the problems of poor adsorption effect and cumbersome process, and achieve adsorption capacity Strong, high specific surface area, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

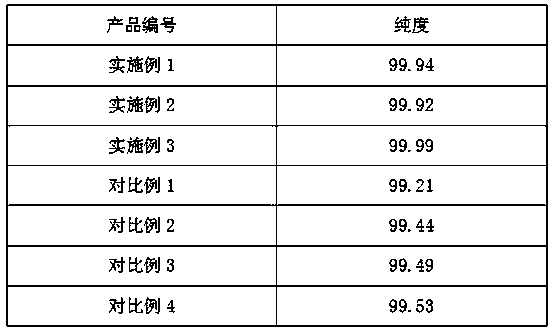

Examples

Embodiment 1

[0020] In the reaction kettle, add 100Kg of porous cellulose acetate microspheres, 7.5Kg of cis,cis-2,4-hexadienedioic acid, (2R,3S)-1-carboxy-4-trifluoromethyl-2,3 -Dihydroxycyclohexa-4,6-diene 1Kg, tetrakis-(trimethylsilene ether)titanium 0.2Kg, 1,2-bis(trimethylsiloxy)cyclobutene 2Kg, benzyl peroxide Acyl 0.3Kg, water 400Kg, heated up to 80°C, reacted for 7.5h, the product was washed with water and dried to obtain the adsorption material for diisononyl 1,2-cyclohexanedicarboxylate.

Embodiment 2

[0022] In the reaction kettle, add 100Kg of porous cellulose acetate microspheres, 5Kg of cis,cis-2,4-hexadienedioic acid, (2R,3S)-1-carboxy-4-trifluoromethyl-2,3- Dihydroxycyclohexa-4,6-diene 0.5Kg, tetrakis-(trimethylsilene ether)titanium 0.1Kg, 1,2-bis(trimethylsiloxy)cyclobutene 1Kg, benzyl peroxide Acyl 0.1Kg, water 300Kg, heated to 70°C, reacted for 5h, the product was washed with water and dried to obtain the adsorption material for diisononyl 1,2-cyclohexanedicarboxylate.

Embodiment 3

[0024] In the reaction kettle, add 100Kg of porous cellulose acetate microspheres, 10Kg of cis,cis-2,4-hexadienedioic acid, (2R,3S)-1-carboxy-4-trifluoromethyl-2,3- Dihydroxycyclohexa-4,6-diene 1.5Kg, tetrakis-(trimethylsilene ether)titanium 0.3Kg, 1,2-bis(trimethylsiloxy)cyclobutene 3Kg, benzyl peroxide Acyl 0.5Kg, water 500Kg, heated up to 90°C, reacted for 10h, the product was washed with water and dried to obtain the adsorption material for diisononyl 1,2-cyclohexanedicarboxylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com