A method for treating ammonia-containing wastewater

A treatment method and technology of sewage treatment plants, applied in biological water/sewage treatment, special compound water treatment, water/sludge/sewage treatment, etc., can solve problems such as no effect, improve effluent water quality, and strengthen synergy , the effect of increasing the denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

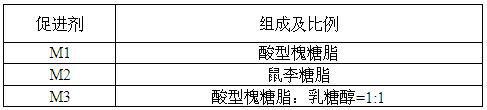

Embodiment 1

[0025] During the catalyst production process of an oil refinery, a waste water containing refractory organic matter and ammonia nitrogen will be produced. The water quality characteristics are: pH9.2, COD 900mg / L, BOD 100mg / L, ammonia nitrogen 137mg / L. During the long-term operation of the system, the ammonia nitrogen removal effect is poor, resulting in a total nitrogen concentration of up to 152mg / L, the SVI of the activated sludge is greater than 200mL / g, and the sedimentation performance is poor.

[0026]Treat according to the method of the present invention, adjust the sludge concentration of the treatment system to be 1000mg / L. According to the accelerator concentration in the treatment system is 1.0mg / L, the growth accelerator M1 is added, and the DO in the system is controlled to be about 3.0mg / L at the initial stage. When the ammonia nitrogen removal rate is greater than 50%, add liquid bacterial suspension A to the system every day according to 0.008% of the volume ...

Embodiment 2

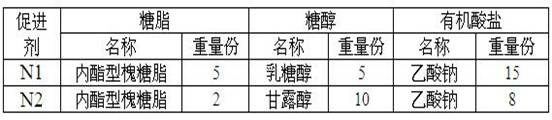

[0028] Treat the same waste water as in Example 1, and adjust the sludge concentration of the treatment system to be 1500 mg / L. Add microbial growth promoter M2 according to the concentration of accelerator in the treatment system at 1.0mg / L, and control the DO in the system at about 2.5mg / L at the initial stage. When the ammonia nitrogen removal rate is greater than 70%, add liquid bacterial suspension B to the system every day at 0.005% of the volume of wastewater treated per hour, and add microbial growth promoters according to the accelerator concentration in the reaction system at 0.5mg / L N2, while controlling DO at about 1.5mg / L. When the removal rate of ammonia nitrogen is greater than 85%, DO is controlled at about 0.4mg / L and administered for 13 days. The sewage treatment temperature is 25°C and the pH is 8.5. The SVI in the detection system is less than 200mL / g. After one month of operation, the concentration of ammonia nitrogen in the effluent after analysis and t...

Embodiment 3

[0030] A chemical wastewater containing refractory organic pollutants, the water quality characteristics are: COD is about 2000mg / L, BOD is about 450mg / L, ammonia nitrogen is about 150mg / L, and pH is 8.7. After using the conventional activated sludge treatment process, the COD of the effluent is still as high as 300mg / L, the ammonia nitrogen is still as high as 200mg / L, and the total nitrogen is as high as 250mg / L.

[0031] Treat according to the method of the present invention, and adjust the sludge concentration of the treatment system to be 2000mg / L. Add microbial growth promoter M3 according to the concentration of accelerator in the treatment system at 0.8mg / L, and control the DO in the system at about 2.0mg / L at the initial stage. When the removal rate of ammonia nitrogen is greater than 60%, add liquid bacterial suspension C to the system every day according to 0.008% of the volume of wastewater treated per hour, and add microbial growth promoter according to the accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com