Water-in-oil drilling fluid and preparation method thereof

A water-in-oil based drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor suspension capacity and high temperature resistance, increased filtration loss, high oil solubility, etc., to achieve The effect of improving performance, simplifying production process and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

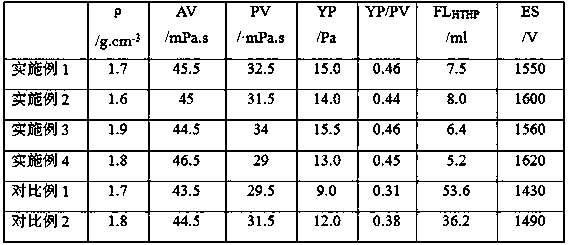

Examples

Embodiment 1

[0045] Heat 380g of asphalt with a softening point of 125.6°C to 165°C in an asphalt reactor, add 11.5g of maleic anhydride, and feed inert gas to keep the pressure of the asphalt reactor at 0.45MPa, and react for 3.5 hours to obtain grafted Activate asphalt; put 90g of sulfur powder in a closed sulfur reactor, heat to 290°C, add 0.09g of isoprene after 40 minutes, and feed N at the same time 2 Keep the pressure at 1.2MPa. After the asphalt grafting reaction is completed, open the valve of the reaction kettle at the same time, spray the two liquids into the contact tower, the molten sulfur enters from the upper part of the tower, and the molten asphalt enters from the lower part of the tower, so that the two can fully contact in countercurrent and keep 30 minute. Open the discharge valve at the bottom of the contact tower, quickly spray the liquid into cold water for quenching, and form uniform particles of asphalt and high elastic sulfur, which are suspended in the quenching...

Embodiment 2

[0048] Heat 400g of asphalt with a softening point of 135.5°C to 170°C in an asphalt reactor, add 16.5g of polyoxalic anhydride, and pass inert gas to keep the pressure of the asphalt reactor at 0.6MPa, and react for 4.5 hours to obtain graft activation Asphalt; put 80g of sulfur powder in a closed sulfur reactor, heat to 300°C, add 0.1g of 1-dodecene after 50 minutes, and feed N 2 Keep the pressure at 1.5MPa. After the asphalt grafting reaction is completed, open the valve of the reaction kettle at the same time, spray the two liquids into the contact tower, the molten sulfur enters from the upper part of the tower, and the molten asphalt enters from the lower part of the tower, so that the two can fully contact in countercurrent and keep 40 minute. Open the discharge valve at the bottom of the contact tower, quickly spray the liquid into cold water for quenching, and form uniform particles of asphalt and high elastic sulfur, which are suspended in the quenching liquid. Kee...

Embodiment 3

[0051] Heat 425g of asphalt with a softening point of 145.4°C to 185°C in an asphalt reactor, add 15.2g of polyisobutylene succinic anhydride, and feed inert gas to keep the pressure of the asphalt reactor at 0.9MPa, and react for 5.5 hours to obtain grafted Activate asphalt; put 120g of sulfur powder in a closed sulfur reaction kettle, heat to 320°C, add 0.24g of hexachloro-p-xylene after 55 minutes, and feed N 2 Keep the pressure at 1.2MPa. After the asphalt grafting reaction is completed, open the valve of the reaction kettle at the same time, spray the two liquids into the contact tower, the molten sulfur enters from the upper part of the tower, and the molten asphalt enters from the lower part of the tower, so that the two can fully contact in countercurrent and keep 45 minute. Open the discharge valve at the bottom of the contact tower, quickly spray the liquid into cold water for quenching, and form uniform particles of asphalt and high elastic sulfur, which are suspen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com