Method for increasing relative content of 2-position palmitic acid in oil

A relative content, palmitic acid technology, applied in the field of oil processing, can solve the problem of not paying attention to OPO processing and refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 800g of palm stearin (IV16) and 200g of high oleic sunflower oil were mixed, heated to 105°C, and stirred for 30min under vacuum for dehydration. Add 1 g of sodium methoxide, stir the reaction in vacuum at 105°C for 30 min, add 20 g of citric acid aqueous solution (15% by weight), and stir for 20 min to terminate the reaction. The reactant was repeatedly washed with hot water to remove soap. Heating to 105°C, stirring in a vacuum for 30 minutes for dehydration and drying to obtain transesterified oil. Take 500g of the above-mentioned transesterified fat and 1000g of oleic acid and mix them, and pass through an enzyme column filled with 100g of Lipozyme RM IM according to a flow rate of 200g / h, and the reaction temperature is controlled at 60°C. Gross OPO-1 eluting from the enzyme column was collected.

[0058] Take 500g of gross OPO-1, add lipase G50 according to 250U enzyme activity per gram of oil, add deionized water accounting for 10% of oil weight, stir at 30°C f...

Embodiment 2

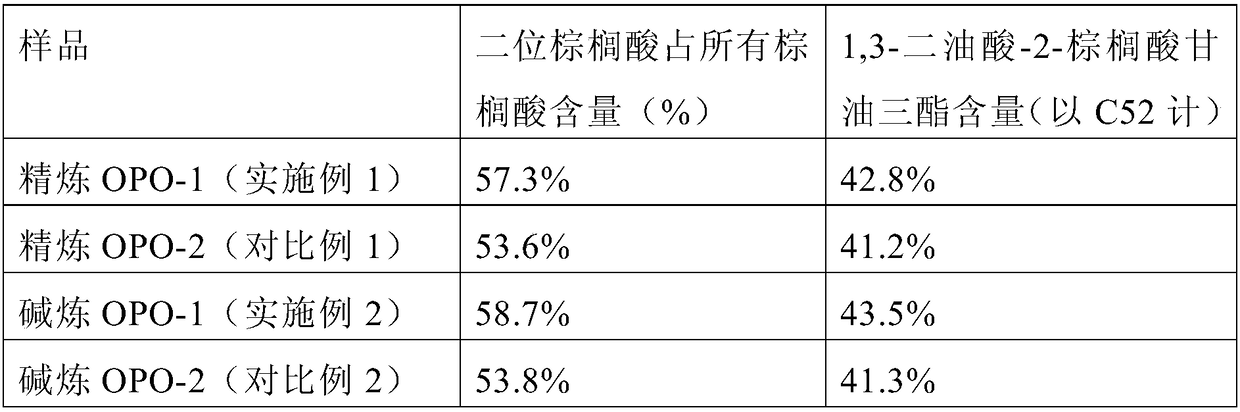

[0062] Take 1000 g of the wool OPO-1 prepared in Example 1, and remove free fatty acid by molecular distillation. Take 200g of deacidified oil, add lipase G50 according to 5U enzyme activity per gram of oil, add deionized water accounting for 1% of the oil weight, and stir at 20°C for 24 hours. Heat the washed oil to 80°C, add an appropriate amount of lye according to the acid value of the oil, stir for 30 minutes, and centrifuge to get the light phase. The above-mentioned grease was heated to 105° C. under vacuum, and 1.5% activated clay by weight of the grease was added, kept stirring under vacuum for 30 minutes, and filtered to obtain decolorized grease. Nitrogen gas (as a stirring and deodorizing medium) is passed through the decolorized oil, the vacuum degree is about 10-20mBar, and it is kept at 240°C for 1 hour for deodorization to obtain alkali-refined OPO-1, and its two-position palmitic acid accounts for all palmitic acid content and 1,3-dioleic acid-2-palmitic acid...

Embodiment 3

[0069] Heat 1000 g of palm stearin (IV16) to 105° C. and stir under vacuum for 30 min for dehydration. Add 1 g of sodium methoxide, stir the reaction in vacuum at 105°C for 30 min, add 20 g of citric acid aqueous solution (15% by weight), and stir for 20 min to terminate the reaction. The reactant was repeatedly washed with hot water to remove soap. Heating to 105°C, stirring in a vacuum for 30 minutes for dehydration and drying to obtain transesterified oil. Take 500g of the above-mentioned transesterified fat and 1000g of oleic acid and mix them, and pass through an enzyme column filled with 100g of Lipozyme RM IM according to a flow rate of 200g / h, and the reaction temperature is controlled at 60°C. Gross OPO-3 eluting from the enzyme column was collected.

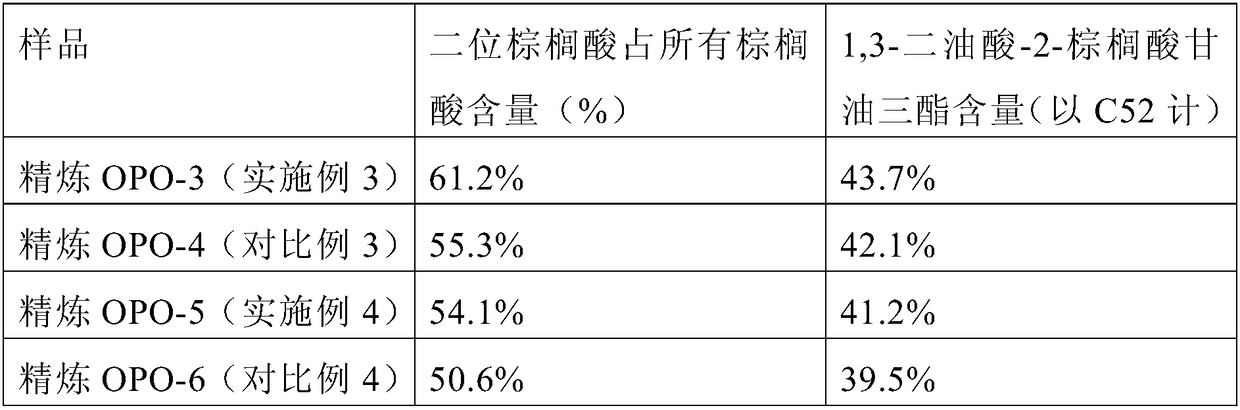

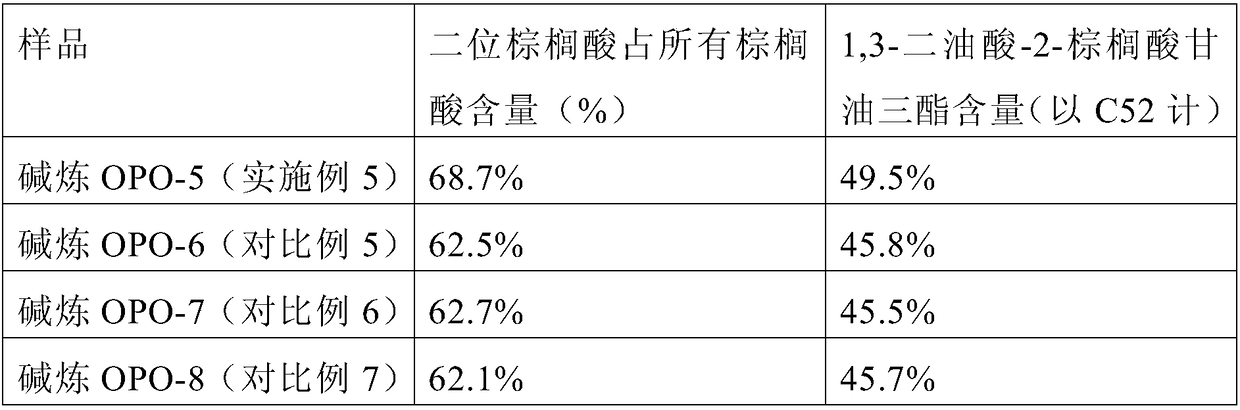

[0070]Take 500g of gross OPO-3, add lipase G50 according to 500U enzyme activity per gram of oil, add deionized water accounting for 20% of oil weight, stir at 40°C for 1 hour, and centrifuge to remove water. Remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com