Method of producing beta-carotene by genetically engineered bacterium and genetically engineered bacterium thereof

A technology of genetically engineered bacteria and carotene, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve problems such as high cost, complicated fermentation conditions, and difficult industrial production, and achieve high yield and simple fermentation conditions , significant production value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The import of embodiment 1 Yarrowia lipolytic yeast gene

[0059] This example mainly describes the gene transformation method of Yarrowia lipolytica.

[0060] Competent cell preparation process

[0061] 1. Inoculate a single colony of Yarrowia lipolytica into 5ml of YPD liquid medium (citric acid-sodium citrate buffer to adjust the pH to 4.0), 28°C, 220rpm shaking culture for 10-12h;

[0062] 2. Transfer 50-100 μL of the above culture solution to 10 ml YPD liquid medium (pH 4.0), and culture overnight at 28°C and 220 rpm until the cell OD 600 About 5.5 or so;

[0063] 3. Centrifuge the culture medium at 28°C and 3500rpm for 5min;

[0064] 4. Discard the supernatant and wash the cells twice with 10ml 1×TE buffer;

[0065] 5. Dilute the suspension with about 20ml of 0.1M LiAc (pH6.0) to make the cell concentration reach 5×10 7 / ml;

[0066] 6. Gently incubate the suspension at 28°C, 100rpm for 1h;

[0067] 7. Centrifuge the culture solution at 28°C and 3500rpm for...

Embodiment 2

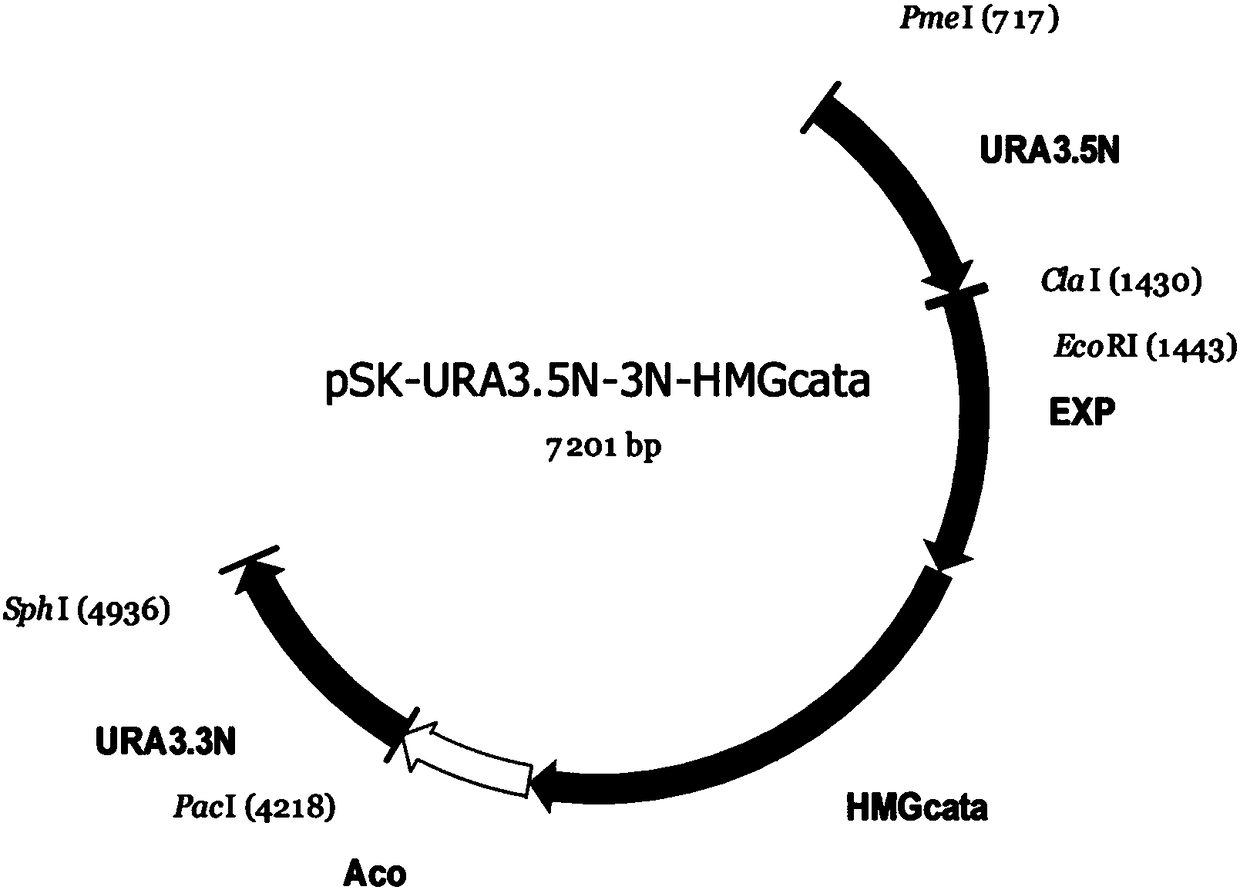

[0073] The acquisition of embodiment 2 URA3 deletion strain

[0074] HMG-CoA reductase is an important rate-limiting enzyme in the mevalonate pathway, catalyzing the conversion of HMG-CoA to mevalonate. To increase β-carotene production, we redirected carbon metabolism to the isoprenoid pathway by cloning expressing the catalytic site of HMG-CoA reductase. The HMG-CoA reductase gene from Yarrowia lipolytica was cloned, totaling 3000bp, its catalytic site was intercepted at 1500-3000bp, and the ATG start codon was added at the start site. In order to make this sequence express normally, the Exp1 promoter and the Aco terminator were added upstream and downstream respectively to obtain the complete cloned expression element Exp1-HMG-CoA cata -Aco, and then integrate the upstream and downstream homologous fragments of the URA3 gene to obtain the plasmid pSK-HMG cata -URA3.5N-3N, the sequence of this plasmid is shown in SEQ ID NO1 (referring to table 2, figure 2 ). The PmeI / Sp...

Embodiment 3 3

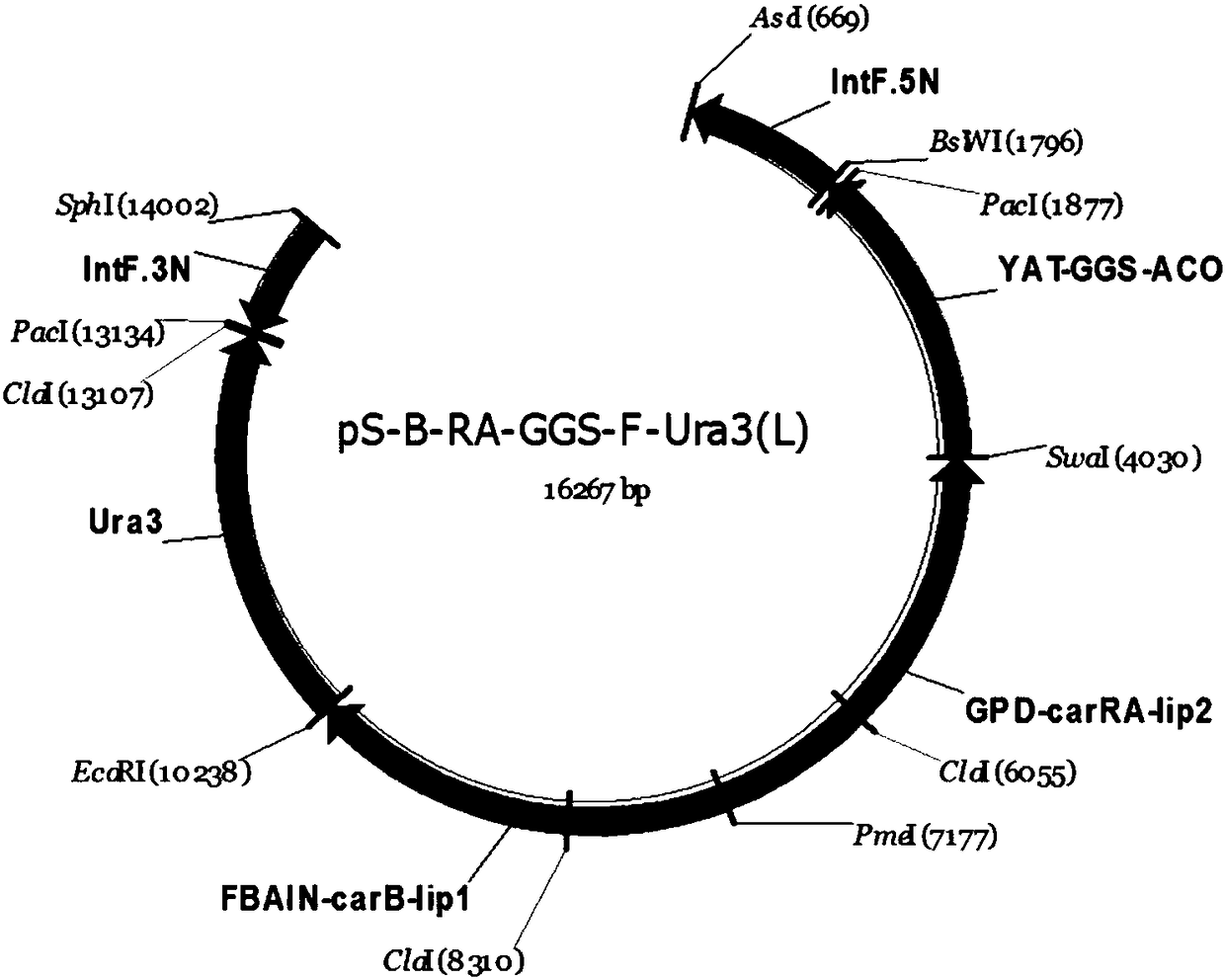

[0077] Embodiment 3 Expression of B. trispora β-carotene gene

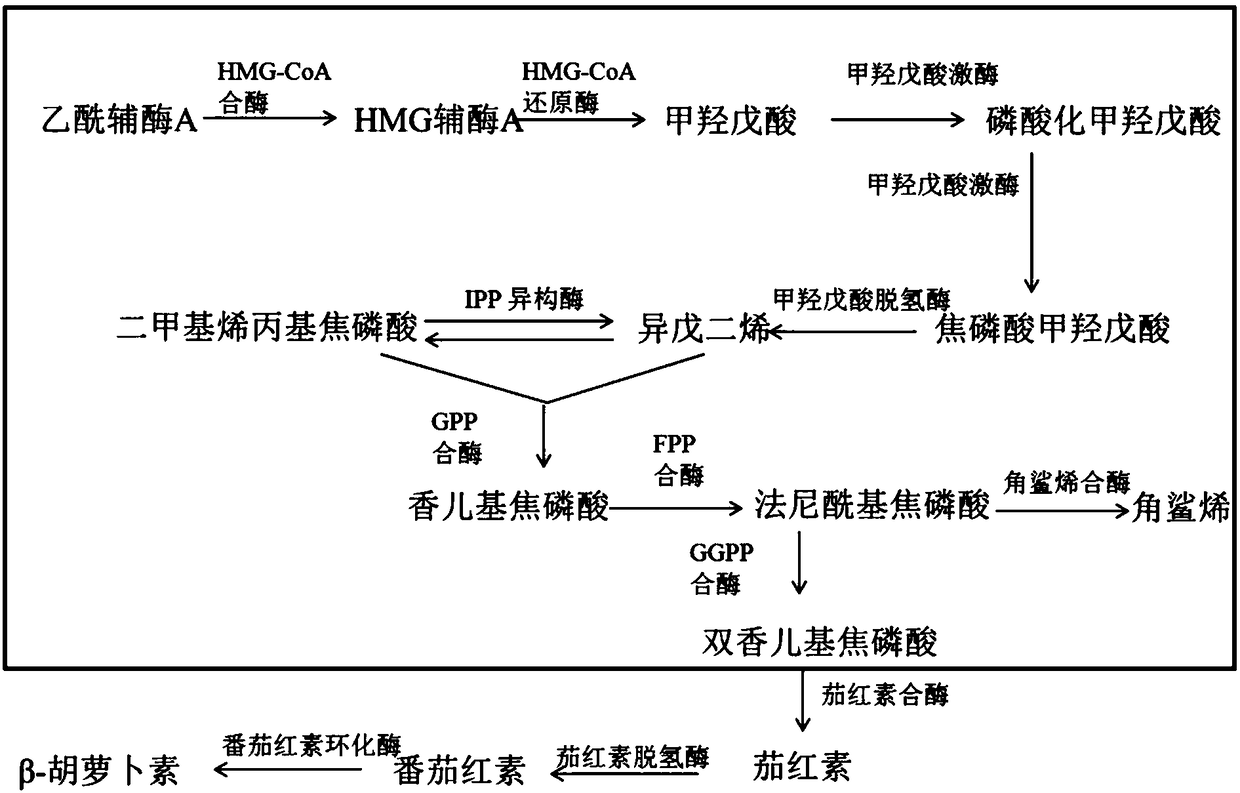

[0078] This embodiment mainly describes the construction and expression of B. trispora β-carotene in Yarrowia lipolytica strain (see figure 1 ).

[0079]The constructed integrated plasmid pS-B-RA-GGS-F-U(L) mainly includes carB (lycopene dehydrogenase) and carRA (lycopene synthase and lycopene cyclase) derived from B. trispora ) and the GGS gene (bisgeranyl pyrophosphate synthase).

[0080] The GGS gene is cloned from Yarrowia lipolytica ATCC20362, and the specific sequence of the GGS gene is shown in SEQ ID NO.2.

[0081] The CarRA gene was cloned from B. trispora, and optimized according to the codon preference of Yarrowia lipolytica. The sequence of the optimized CarRA gene is shown in SEQ ID NO.3.

[0082] The CarB gene was cloned from B. trispora, and optimized according to the codon preference of Yarrowia lipolytica. The sequence of the optimized CarB gene is shown in SEQ ID NO.4. The above genes were ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com