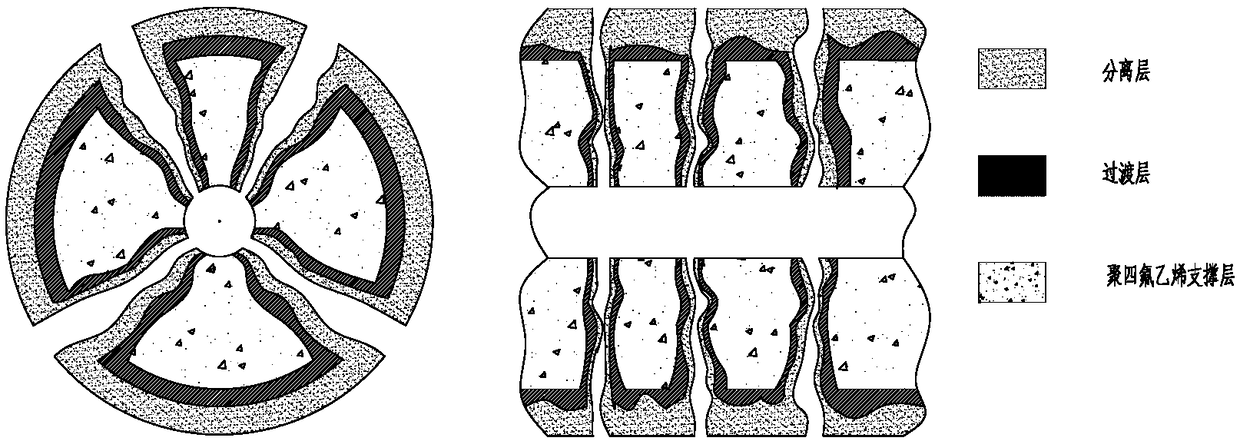

Three-layer polytetrafluoroethylene hollow fiber composite membrane

A polytetrafluoroethylene and fiber composite technology, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of weak bonding, poor surface wettability, easy peeling, etc., and achieve good industrial application prospects, Enhanced firmness, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After sieving the PTFE dispersion resin through a 10-mesh sieve, uniformly mix it with 20wt% lubricant at 17°C, and then ripen it at room temperature for 24 hours, then pre-press, degrease, stretch and sinter to prepare a PTFE hollow fiber membrane. The average pore diameter is 1.4 μm, and the porosity is 60%.

[0016] Dissolve 1g of boric acid and 10g of KH-550 in 89g of ethanol, stir and reflux at 80°C for 10min to prepare the surface modifier.

[0017] Soak the PTFE hollow fiber membrane in the surface modifier for 5 minutes, take it out, dry it for 20 minutes, soak it again for 5 minutes, then dry it overnight, put it in an oven, bake it at 90°C for 15 minutes, and get the adhesion transition layer PTFE hollow fiber membrane.

[0018] Dissolve 14g of polyvinylidene fluoride (PVDF) and 8g of ethylene glycol in 78g of dimethylacetamide, mechanically stir for 12 hours at 65°C to prepare a casting solution, filter, and defoam.

[0019] Under 0.2MPa, the modified PTFE ...

Embodiment 2

[0021] After sieving the PTFE dispersion resin through a 10-mesh sieve, uniformly mix it with 20wt% lubricant at 17°C, and then ripen it at room temperature for 24 hours, then pre-press, degrease, stretch and sinter to prepare a PTFE hollow fiber membrane. The average pore diameter is 1.4 μm, and the porosity is 60%.

[0022] Dissolve 1g of boric acid and 20g of KH-550 in 79g of ethanol, stir and reflux at 80°C for 10min to prepare a surface modifier.

[0023] Soak the PTFE hollow fiber membrane in the surface modifier for 5 minutes, take it out, dry it for 20 minutes, soak it again for 5 minutes, then dry it overnight, put it in an oven, bake it at 90°C for 15 minutes, and get the adhesion transition layer PTFE hollow fiber membrane.

[0024] Dissolve 14g of polyvinylidene fluoride (PVDF) and 8g of ethylene glycol in 78g of dimethylacetamide, mechanically stir for 12 hours at 65°C to prepare a casting solution, filter, and defoam.

[0025] Under 0.2MPa, the modified PTFE ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com