Catalyst and method for direct conversion of synthesis gas for preparation of low carbon olefins

A catalyst and synthesis gas technology, which is applied in catalyst activation/preparation, molecular sieve catalyst, hydrocarbon production from carbon oxides, etc. The effect of low methane selectivity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

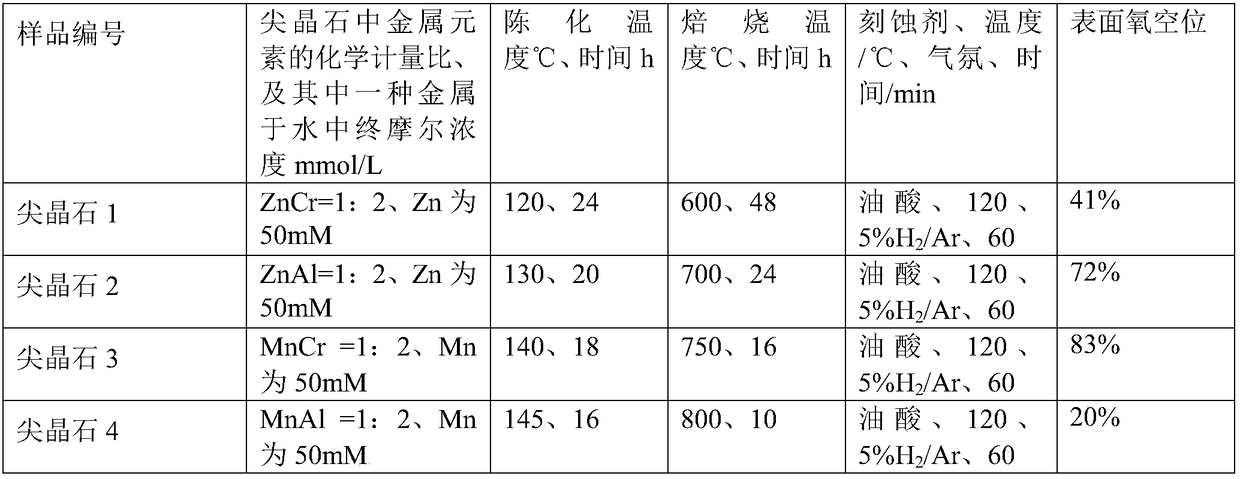

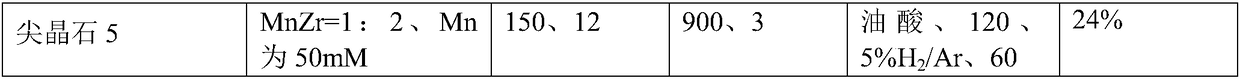

[0031] One, the preparation of catalyst A

[0032] (1), the etching method synthesizes the ZnO material with polar surface:

[0033] (1) Weigh 0.446g (1.5mmol) Zn(NO3) 2 6H2O, then weigh 0.480g (12mmol) NaOH and add it to the above container, then weigh 30ml deionized water and add it to the container, stir for more than 0.5h, Allow the solution to mix well. The temperature was raised to 160°C, the reaction time was 20 hours, and the precipitate was decomposed into zinc oxide; naturally cooled to room temperature. The reaction solution was centrifuged to collect the precipitate after centrifugation, and washed twice with deionized water to obtain ZnO oxide;

[0034] (2) using an etchant, ultrasonically mixing with the ZnO oxide at room temperature, soaking the ZnO oxide in the etchant solution, and forming a complex or direct reduction reaction between the etchant and the zinc oxide;

[0035] The above suspension is heated, then taken out, washed and filtered to obtain a nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com