Preparation method of ceramic block body with hierarchical pore structure by using bacterial cellulose as biological template

A bacterial cellulose, biological template technology, applied in ceramic products, household appliances, other household appliances, etc., to achieve high mass transfer capacity, beneficial to recycling and reuse, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

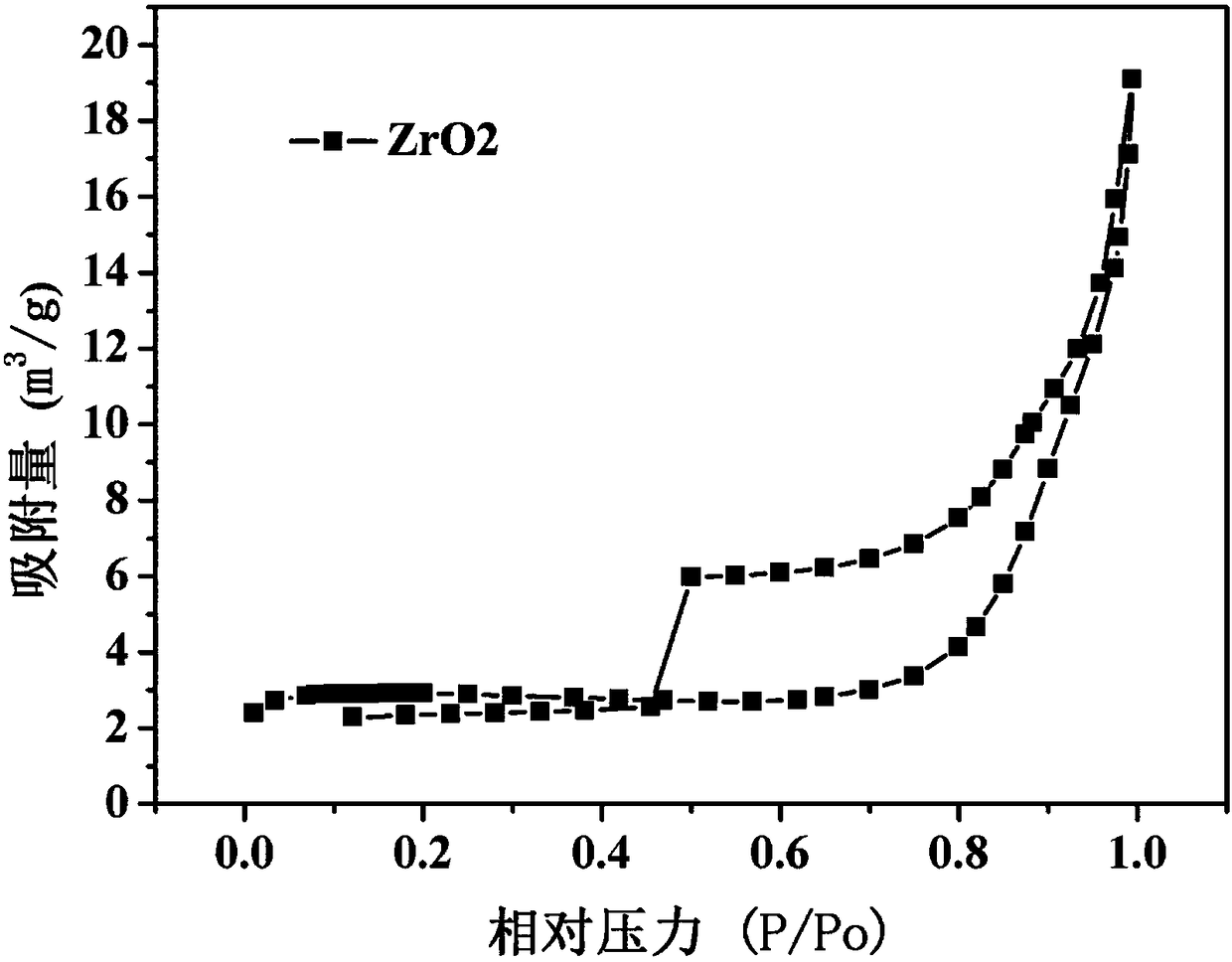

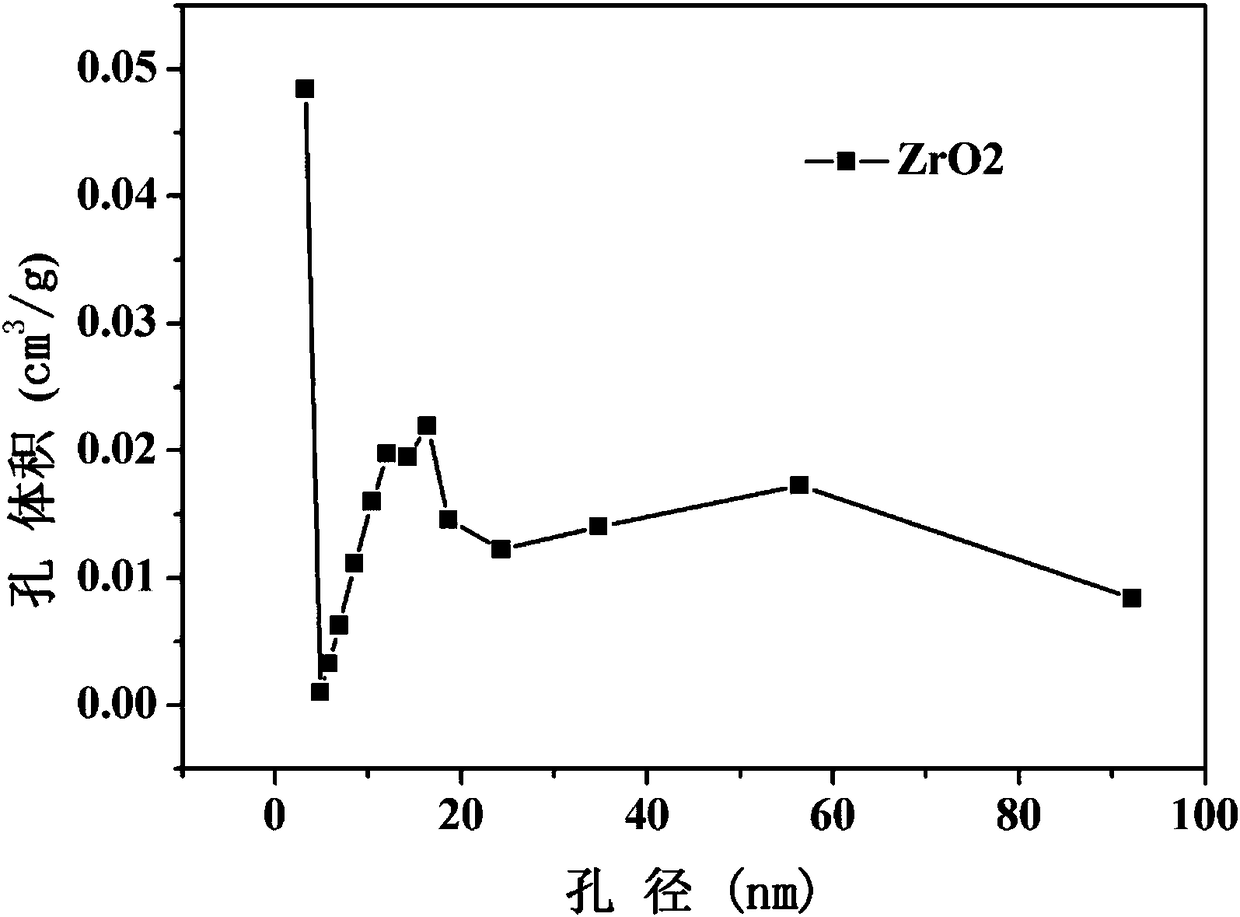

[0039] Using bacterial cellulose as a biological template to prepare a ceramic block with a hierarchical porous structure, specifically includes the following steps:

[0040] (1) Soak the hydrogel of bacterial cellulose in a zirconia precursor aqueous solution with a concentration of 0.1 g / mL for 48 hours;

[0041] (2) Transfer the bacterial cellulose gel soaked in the aqueous solution of the zirconia peroxide precursor to a container, then place the container at -40°C for freezing, and the freezing time is 24 hours;

[0042] (3) Place the frozen bacterial cellulose gel in a freeze dryer, the freezing temperature of the freeze dryer is -50°C, and the freeze drying time is 24 hours;

[0043] (4) The freeze-dried sample is placed in an oven for curing, the curing temperature and curing time are 200°C and 2 hours respectively; after curing, the sample is stored in a desiccator;

[0044](5) Sinter the sample solidified in step (4), the sintering atmosphere is air, the temperature...

Embodiment 2

[0047] Using bacterial cellulose as a biological template to prepare a ceramic block with a hierarchical porous structure, specifically includes the following steps:

[0048] (1) Soak the hydrogel of bacterial cellulose in an aqueous solution of zirconia precursor with a concentration of 0.2g / mL, and the soaking time is 48 hours;

[0049] (2) The bacterial cellulose gel soaked in the aqueous solution of the zirconia peroxide precursor is transferred to the container, and then the container is placed under liquid nitrogen for freezing, and the freezing time is 15 minutes;

[0050] (3) Place the frozen bacterial cellulose gel in a freeze dryer, the freezing temperature of the freeze dryer is -50°C, and the freeze drying time is 48 hours;

[0051] (4) The freeze-dried sample is placed in an oven for curing, the curing temperature and curing time are 200°C and 2 hours respectively; after curing, the sample is stored in a desiccator;

[0052] (5) Sinter the sample solidified in st...

Embodiment 3

[0056] Using bacterial cellulose as a biological template to prepare a ceramic block with a hierarchical porous structure, specifically includes the following steps:

[0057] (1) Soak the hydrogel of bacterial cellulose in an aqueous solution of titanium oxide precursor with a concentration of 0.2 g / mL for 48 hours;

[0058] (2) Transfer the bacterial cellulose gel soaked in the titanium peroxide precursor aqueous solution to a container, and then place the container at -40°C for freezing, and the freezing time is 24 hours;

[0059] (3) Place the frozen bacterial cellulose gel in a freeze dryer, the freezing temperature of the freeze dryer is -50°C, and the freeze drying time is 24 hours;

[0060] (4) The freeze-dried sample is placed in an oven for curing, the curing temperature and curing time are 200°C and 2 hours respectively; after curing, the sample is stored in a desiccator;

[0061] (5) The sample solidified in step (4) is sintered once, the sintering atmosphere is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com