Catalyst for one-step hydrogenation of carbon dioxide to prepare aromatic hydrocarbons, and preparation method and application thereof

A carbon dioxide and catalyst technology, applied in the field of coal chemical industry, can solve the problems of short life, complex phase structure, low Fischer-Tropsch activity, etc., and achieve the effects of small size, large specific surface area, and reduced selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

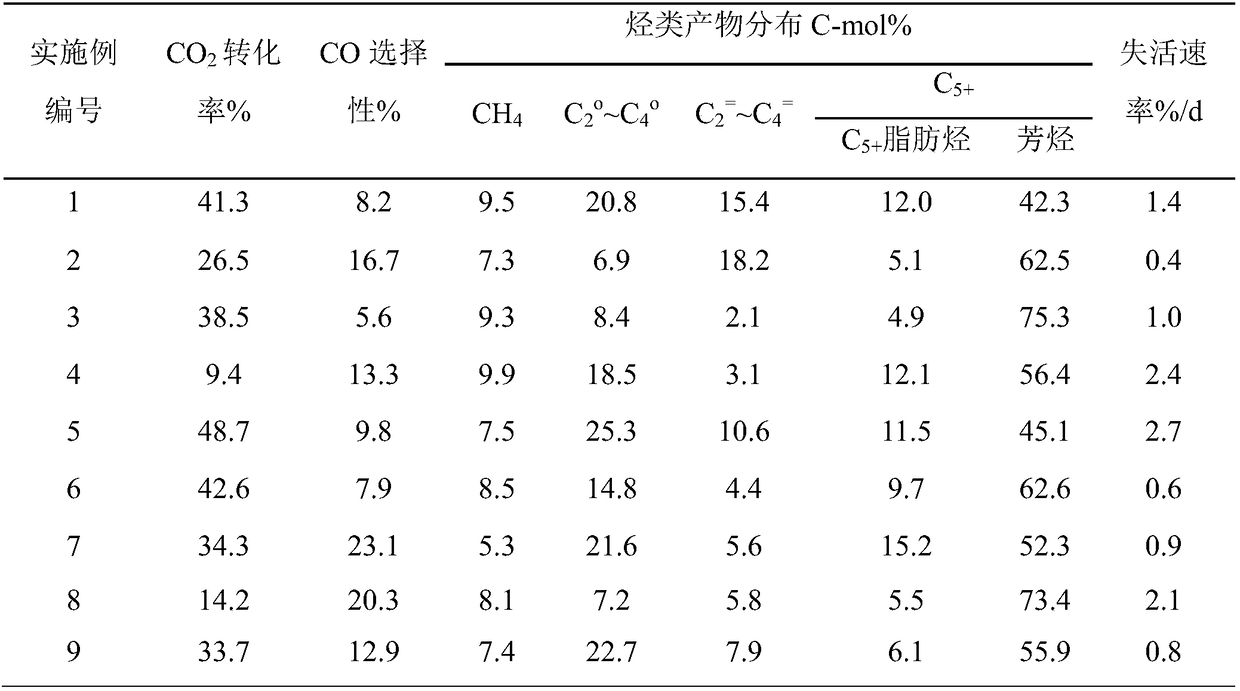

Examples

Embodiment 1

[0047] 96.96g Fe(NO 3 ) 3 9H 2 O and 51.52gZr(NO 3 ) 4 ·5H 2 O was added to 300mL deionized water to prepare a mixed metal salt solution with a concentration of 0.96mol / L, and 60g NaOH was added to 15L deionized water to prepare a 0.1mol / L precipitant solution. Add the precipitant solution dropwise to the metal salt solution at a temperature of 50°C. The dropping process needs to be carried out under ultrasonic vibration with a power of 160W, and the final pH value is kept at 10. After aging at 90°C for 3 hours, the resulting precipitate was washed three times with deionized water under ultrasonic vibration with a power of 80W, and the amount of water required for each washing was calculated as 50mL of deionized water per gram of filter cake. Then dry at 110°C for 15 hours, and then bake at 250°C for 8 hours to obtain metal oxides. Grind the metal oxide in an agate mortar for 0.5h, then press into tablets and sieve to obtain 40-60 mesh metal oxide particles (the molar ra...

Embodiment 2

[0050] 30.30g Fe(NO 3 ) 3 9H 2 O and 6.04gCu(NO 3 ) 2 ·3H 2 O was added to 1000mL deionized water to prepare a mixed metal salt solution with a concentration of 0.1mol / L, and 80g NaOH was added to 4L deionized water to prepare a 0.5mol / L precipitant solution. Add the precipitant solution dropwise to the metal salt solution at a temperature of 40°C. The dropping process needs to be carried out under ultrasonic vibration with a power of 200W, and the final pH value is kept at 8. After the precipitation reaction is completed, the obtained product is in the After aging at 70°C for 1 hour, the resulting precipitate was washed three times with deionized water under ultrasonic vibration at a power of 40W, and the amount of water required for each washing was calculated as 60mL of deionized water per gram of filter cake. Then dry at 80°C for 6h, and then bake at 500°C for 5h to obtain metal oxide (the molar ratio of Fe and Cu is 3:1). Grinding the metal oxide in an agate mortar ...

Embodiment 3

[0053] 96.96g Fe(NO 3 ) 3 9H 2 O and 17.84gZn(NO 3 ) 2 ·6H 2 O was added to 300mL deionized water to prepare a mixed metal salt solution with a concentration of 1.00mol / L, and 80g NaOH was added to 2L deionized water to prepare a 1.0mol / L precipitant solution. Add the precipitant solution dropwise to the metal salt solution at a temperature of 70°C. The dropping process needs to be carried out under ultrasonic vibration with a power of 100W, and the final pH value is kept at 9. After aging for 0.5 h at ℃, the resulting precipitation was washed 8 times with deionized water under ultrasonic vibration with a power of 90 W, and the amount of water required for each washing was calculated as 20 mL of deionized water per gram of filter cake. Then dry at 100°C for 20h, and then bake at 600°C for 4h to obtain metal oxide (the molar ratio of Fe and Zn is 4:1). Grinding the metal oxide in an agate mortar for 0.6h, then pressing into tablets and sieving to obtain 60-80 mesh metal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com