Preparation method of willow panels

A willow and board technology, applied in wood treatment, wood heating, wood impregnation, etc., can solve the problems of willow prone to insect pests, poor hardness of willow, affecting use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

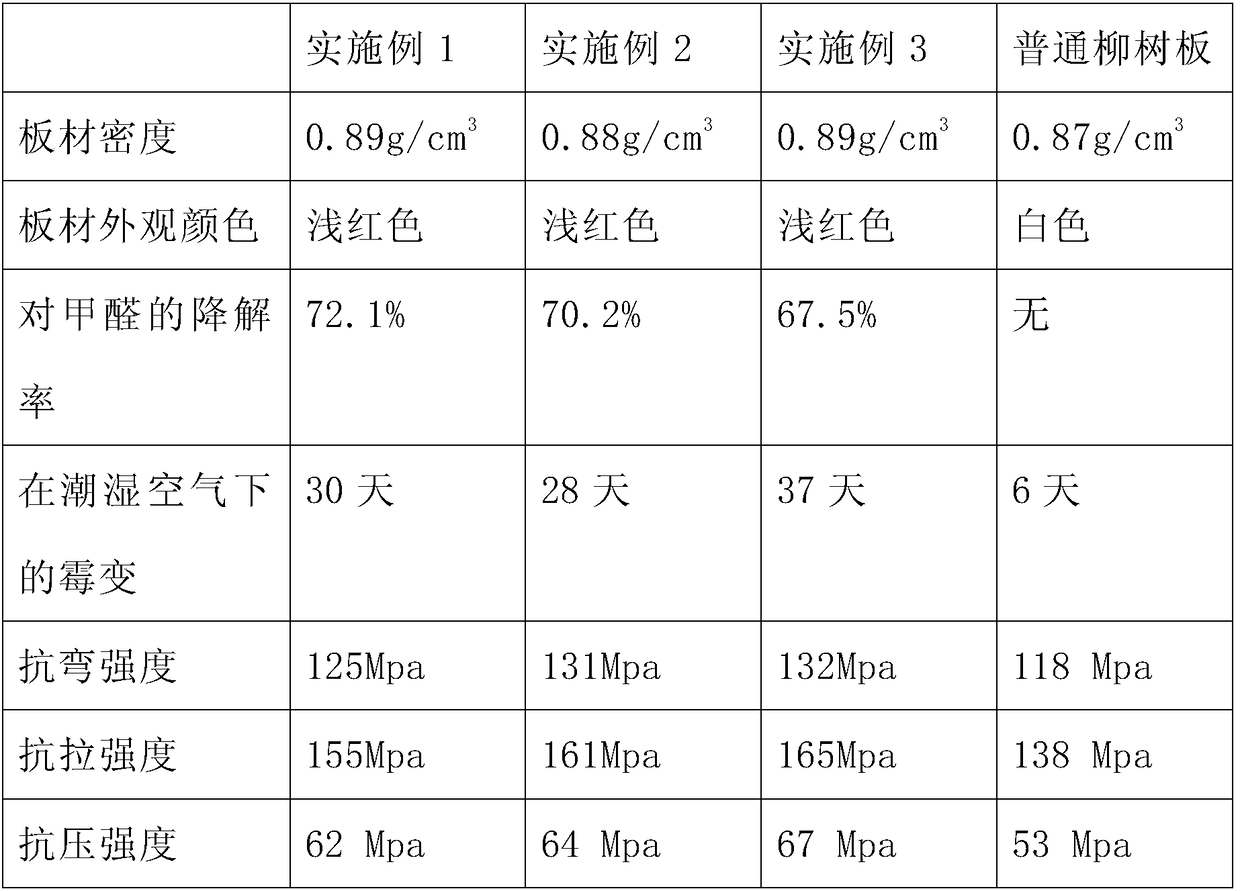

Examples

preparation example Construction

[0018] The preparation method of the soaking liquid is as follows: mixing sodium carbonate, sodium chloride, thiophanate-methyl, and water according to the mass ratio of 50-100:500-600:1-2:2500-3000, stirring to dissolve completely.

[0019] The liquid caustic soda is 3-5 mol / L sodium hydroxide solution.

[0020] The concentration of titanium sulfate in the mixed solution of titanium sulfate and iron sulfate is 1-2 mol / L, the concentration of iron sulfate is 0.2-0.5 mol / L, and the pH of the mixed solution is 0.8-1.0.

[0021] The high temperature treatment adopts microwave heating.

[0022] The surface treatment uses a grinder to polish the surface of the willow board, and then sprays a layer of wax.

Embodiment 1

[0024] A kind of preparation method of willow plank, willow log is cut into the willow log section that length is 3m, bark is peeled off by adopting automatic peeling machine, simultaneously air-dries until the moisture content of willow log section is 4%, then soaks in the soaking liquid, The soaking time is 8 hours, the soaking temperature is 49°C, and then soaked in clear water for 2.5 hours, taken out and aired to a moisture content of 3.5%, and then cut into willow boards with a thickness of 2.5cm by a cutting machine, and then placed Put it into liquid carbon dioxide, put it under the pressure of 4.1 atmospheres, and put it at minus 41°C for 40 minutes, then take it out, put it at 45°C for 1.2 hours, soak it in lye for 85s, remove it, drain it and spray it with water Rinse for 1.8 minutes, and then immerse in the mixed solution of titanium sulfate and iron sulfate. The soaking time is 1.5 hours and the temperature is 45°C. Then take it out and drain it, rinse it with wate...

Embodiment 2

[0031] A method for preparing willow boards, comprising cutting willow logs into willow log sections with a length of 3.1 m, peeling off the bark by using an automatic peeling machine, drying the willow logs until the moisture content of the willow log sections is 3.5%, and then soaking in the soaking solution , the soaking time is 8 hours, the soaking temperature is 49°C, and then soaked in clean water for 3 hours, taken out, aired to a moisture content of 4%, and then cut into willow boards with a thickness of 2cm by a cutting machine, and then placed Put it into liquid carbon dioxide, put it under the pressure of 4 atmospheres and the temperature of minus 40°C for 50 minutes, then take it out, put it at 45°C for 2 hours, soak it in lye for 110s, remove it, drain it and spray it with water Rinse for 2 minutes, then immerse in the mixed solution of titanium sulfate and iron sulfate, soak for 1 hour, and the temperature is 45 ° C, then take it out and drain, rinse with water fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com