Method and system for removing bisphenol A by utilizing crude enzyme liquid of machilus nanmu

A crude enzyme solution and bisphenol technology, applied in the field of plant biology, can solve the problems of desorption secondary pollution, bisphenol A removal, complex operation, etc., and achieve the effect of easy acquisition, low cost and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

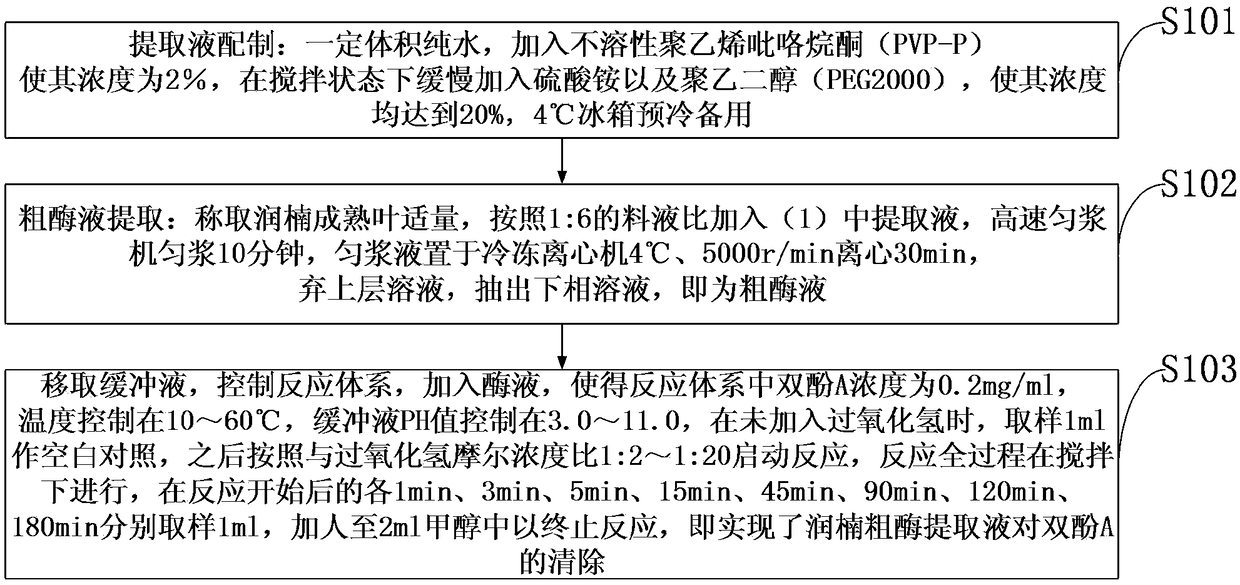

[0028] figure 1 , the method for removing bisphenol A by using Runnan crude enzyme liquid provided by the embodiment of the present invention comprises the following steps:

[0029] S101: Preparation of extract: add a certain volume of pure water, add insoluble polyvinylpyrrolidone (PVP-P) to make its concentration 2%, slowly add ammonium sulfate and polyethylene glycol (PEG2000) under stirring, to make its concentration reach 20%, pre-cooled in a 4°C refrigera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap