Preparation method of tris(2-chloroethyl)amine hydrochloride

A technology of amine hydrochloride and chloroethyl, applied in the field of preparation of triamine hydrochloride, can solve the problems of increased raw material cost, high pollution, high price of thionyl chloride, low cost, realization of recycling, Huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

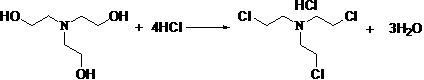

[0025] A kind of preparation method of tris (2-chloroethyl) amine hydrochloride is synthesized by following principle:

[0026]

[0027] The specific operation steps are:

[0028] (1) Add 149g of triethanolamine into the three-necked reaction flask, start stirring, connect the outlet to the buffer bottle, and use 1M sodium hydroxide solution for absorption, start to pass hydrogen chloride under room temperature, the gas flow rate is 500mL / min, and the ventilation time is 45min, pH value is about 3, stop ventilation;

[0029] (2) Add 7.45g of aluminum sulfate, start heating, rise to 150°C, pass hydrogen chloride again, and the gas flow rate is 500mL / min. Distill while reacting, and remove the generated water in time. After reacting for 8 hours, stop heating and stop aeration. Cool down to room temperature, add 30g of absolute ethanol, stir, and filter with suction to obtain a filter cake, vacuum-dry at 50~60°C for 5 hours, and collect 219g of solid, which is the finished ...

Embodiment 2

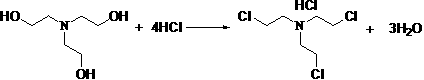

[0031] A kind of preparation method of tris (2-chloroethyl) amine hydrochloride is synthesized by following principle:

[0032]

[0033] The specific operation steps are:

[0034] (1) Add 149g of triethanolamine into the three-necked reaction flask, start stirring, connect the outlet to the buffer bottle, and use 1M sodium hydroxide solution for absorption, start to pass hydrogen chloride under room temperature, the gas flow rate is 300mL / min, and the ventilation time is 75min, pH value is about 2, stop ventilation;

[0035] (2) Add 7.45g of zinc sulfate, start heating, rise to 150°C, pass hydrogen chloride again, and the gas flow rate is 800mL / min. Distill while reacting, and remove the generated water in time. After reacting for 6.5 hours, stop heating and stop aeration. When the temperature is lowered to room temperature, add 30g of absolute ethanol, stir, and filter with suction to obtain a filter cake, and vacuum-dry at 50~60°C for 5 hours, and collect 220g of solid...

Embodiment 3

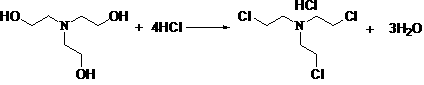

[0037] A kind of preparation method of tris (2-chloroethyl) amine hydrochloride is synthesized by following principle:

[0038]

[0039] The specific operation steps are:

[0040] (1) Add 149g of triethanolamine into the three-necked reaction flask, start stirring, connect the outlet to the buffer bottle, and use 0.1M sodium hydroxide solution for absorption, start to pass hydrogen chloride at room temperature, the gas flow rate is 400mL / min, and the ventilation time 55min, pH value is about 3, stop ventilation;

[0041] (2) Add 14.9g of zinc sulfate, start heating, rise to 170°C, pass hydrogen chloride again, and the gas flow rate is 600mL / min. Distill while reacting, and remove the generated water in time. After reacting for 5 hours, stop heating and stop aeration. Cool down to room temperature, add 45g of absolute ethanol, stir, and filter with suction to obtain a filter cake, vacuum-dry at 50~60°C for 5 hours, and collect 215g of solid, which is the finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com