Continuous modified polystyrene light guide plate production technology, and modified polystyrene light guide plate

A polystyrene, production process technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as the inability to guarantee the clarity of the image quality of liquid crystal display devices, affect the display effect of liquid crystal display devices, and poor dimensional stability of light guide plates, etc., to achieve Reduce processing preparation and melt plasticization process, ensure the clarity of picture quality display, and ensure the effect of picture quality clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

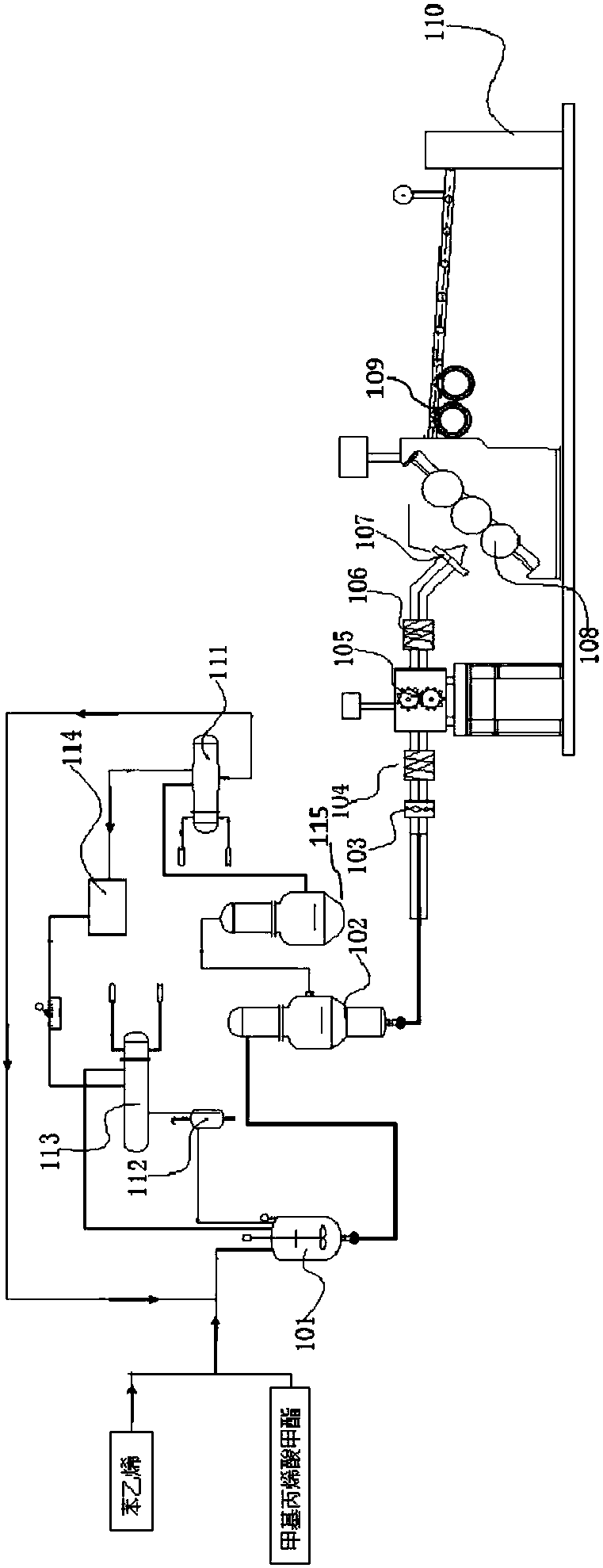

[0074] This embodiment provides a modified polystyrene light guide plate, which is prepared according to the following process, such as figure 1 Shown:

[0075] (a) Add styrene monomer and methyl methacrylate monomer into the reaction kettle 101 and mix them evenly. The mass ratio of the two monomers is 95:5, and carry out polymerization reaction. The polymerization temperature is controlled to be 120° C. to obtain several Modified polystyrene melt with an average molecular weight of 50,000;

[0076] (s) After the modified polystyrene melt is discharged from the reaction kettle 101, the devolatilizer 102 and the filter 103 are passed through the devolatilizer 102 and the filter 103 for devolatilization and filtration, and the low boiling point components and low boiling point components discharged from the devolatilizer 102 are The polymer component first passes through the impurity separator 115 to separate and remove the oligomer component, then transports the low boiling p...

Embodiment 2

[0079] This embodiment provides a modified polystyrene light guide plate, which is prepared according to the following process:

[0080] (a) Add styrene monomer and methyl methacrylate monomer into the reactor for polymerization reaction, the mass ratio of the two is 50:50, the polymerization temperature is controlled at 145°C, and the number average molecular weight is 200,000 Modified polystyrene melt;

[0081] (s) Devolatize and filter the modified polystyrene melt through the devolatilizer and filter in sequence, and continue to discharge the low-boiling components discharged from the devolatilizer and buffer tank into the reactor for recovery use;

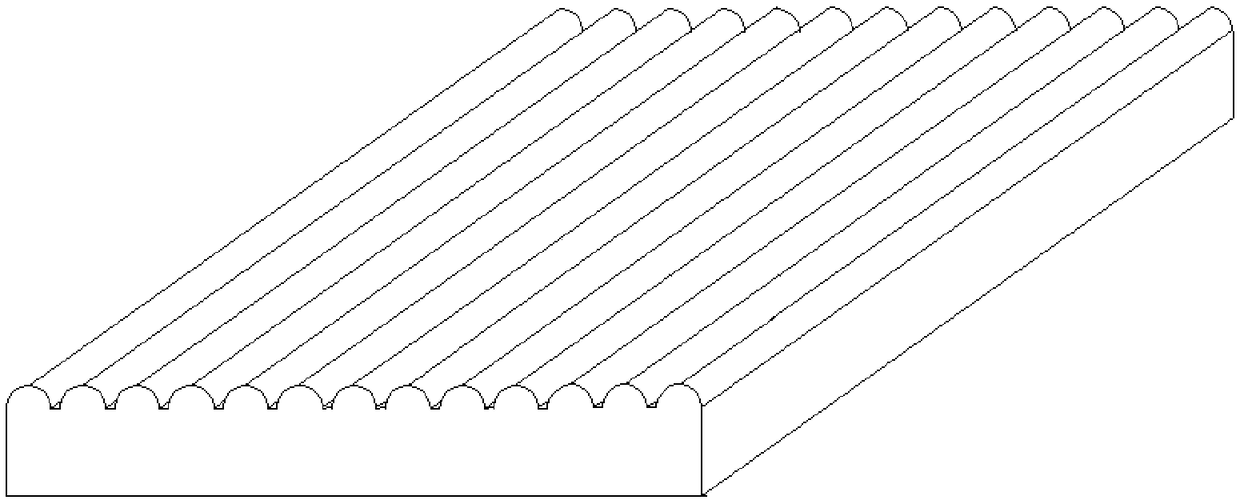

[0082] (b) The filtered modified polystyrene melt is transported to the plate forming system at 230°C and then passed through the first mixer, gear pump, second mixer, extrusion die, three-roll calender and water cooling device, that is, a modified polystyrene light guide plate with a thickness of 2 mm was prepared. Among t...

Embodiment 3

[0084] This embodiment provides a modified polystyrene light guide plate, which is prepared according to the following process:

[0085] (a) Add styrene monomer and methyl methacrylate monomer into the reactor for polymerization reaction, the mass ratio of the two is 80:20, the polymerization temperature is controlled at 140°C, and the number average molecular weight is 100,000 Modified polystyrene melt;

[0086] (s) Devolatize and filter the modified polystyrene melt through the devolatilizer and filter in sequence, and continue to discharge the low-boiling components discharged from the devolatilizer and buffer tank into the reactor for recovery use;

[0087] (b) The filtered modified polystyrene melt is transported to the plate forming system at 220°C, and then passes through the first mixer, gear pump, second mixer, extrusion die, three-roll calender and water cooling A cooler, that is, a modified polystyrene light guide plate with a thickness of 2mm was prepared. Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com