A laser repair method of moving cross head

A technology of laser repair and repair method, which is applied in the field of laser repair of moving crossheads, can solve the problems of microstructure phase transformation residual stress in the heat-affected zone of cracks, and achieves good creep limit, dense interface structure, good resistance to thermal fatigue and fracture performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The 1810 line pc rolling mill of a steel factory moves the cross head.

[0020] Basic information: Specification: 680×1100mm; Weight: 1500kg / piece; Material: SCM440.

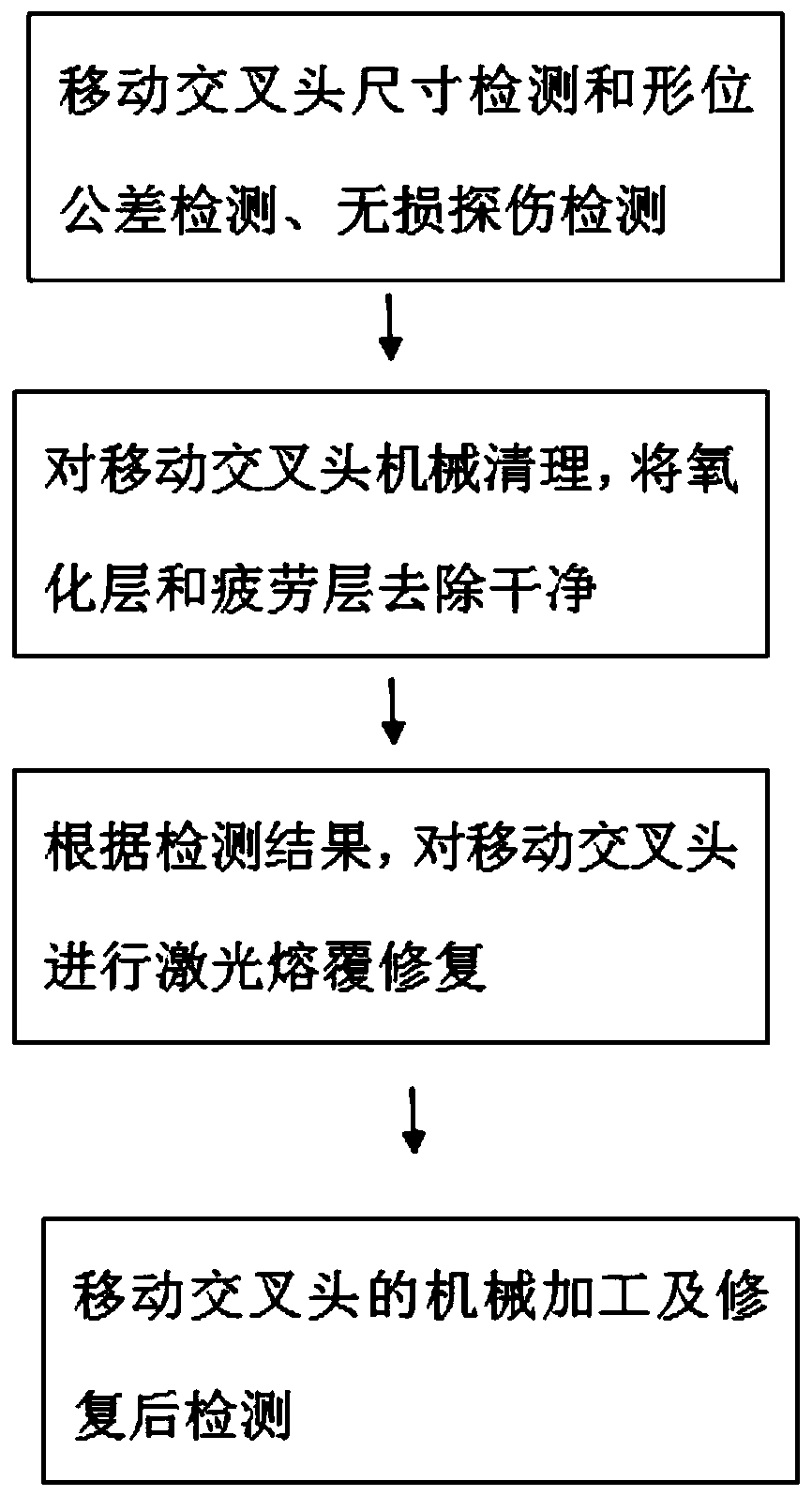

[0021] The repair method includes the following steps:

[0022] Step 1, the size detection and shape tolerance detection of the mobile cross head, the non-destructive testing detection and recording the wear thickness of the mobile cross head.

[0023] Step 2, mechanically clean the parts to be clad, and remove the oxide layer and fatigue layer.

[0024] Step 3: Carry out laser cladding repair on the mobile intersection head according to the detection results, and fuse the cladding material with the parent material of the mobile intersection head to form a cladding layer:

[0025] Fix the moving cross head on the laser CNC machine tool to ensure that the plane to be clad is basically in a horizontal state.

[0026] Step 3 needs to use laser cladding metal powder: Cr: 25%, Mo: 5%, W: 10%, Ti: 5%, Ta: 3%...

Embodiment 2

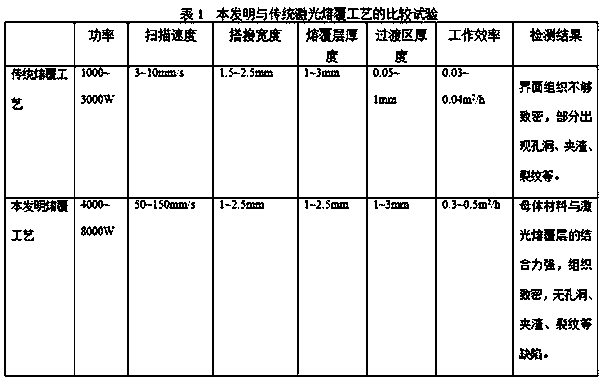

[0033] Comparative test between the present invention and traditional laser cladding process:

[0034] The method of the traditional laser cladding process is the same as that of Example 1, except that the parameters of the cladding process in step 3 are different. The specific parameters and test results are shown in the table below.

[0035]

[0036] The results show that through the laser cladding method of the present invention, the bonding strength between the parent material and the laser cladding layer is not lower than 90% of the original substrate; compared with the traditional cladding process, the cladding layer and its interface structure are denser , fine grains, no holes, slag inclusions, cracks and other defects; the surface hardness of the repair layer is HV350-450, which has high corrosion resistance and wear resistance, and has good creep limit, good durable strength and good resistance Thermal fatigue and fracture properties, therefore, are significantly ...

Embodiment 3

[0047] A laser repair method for moving a cross head, the repair method includes the following steps:

[0048] Step 1, mobile intersection head size detection, shape and position tolerance detection, non-destructive flaw detection;

[0049] Step 2, mechanically clean the mobile cross head, and remove the oxide layer and fatigue layer;

[0050] Step 3, according to the detection result, for the laser repair of the mobile intersection, the cladding material is fused with the parent material of the mobile intersection to form a cladding layer;

[0051] The process parameters of laser repair are: laser power 5000~5500W; spot diameter 10mm; spot moving speed 150mm / s; lap width 2.5mm; modified cladding layer thickness 2mm.

[0052] The laser cladding material is composed of the following components by weight: Cr: 30%, Mo: 8%, W: 15%, Ti: 7.5%, Ta: 5%, Al: 5%, and the balance of Co.

[0053] Step 4, machining of the mobile crosshead and detection after repair;

[0054] Step 5, qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com