Stacker-reclaimer scraper chain full-automatic lubricating system and working method

A scraper chain and lubrication system technology, which is applied in the field of lubrication systems, can solve the problems of reduced service life of the scraper chain, high operating current of the scraper, and unsatisfactory lubrication effect, etc., achieving good lubrication effect, reduced operating noise, The effect of preventing hard friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

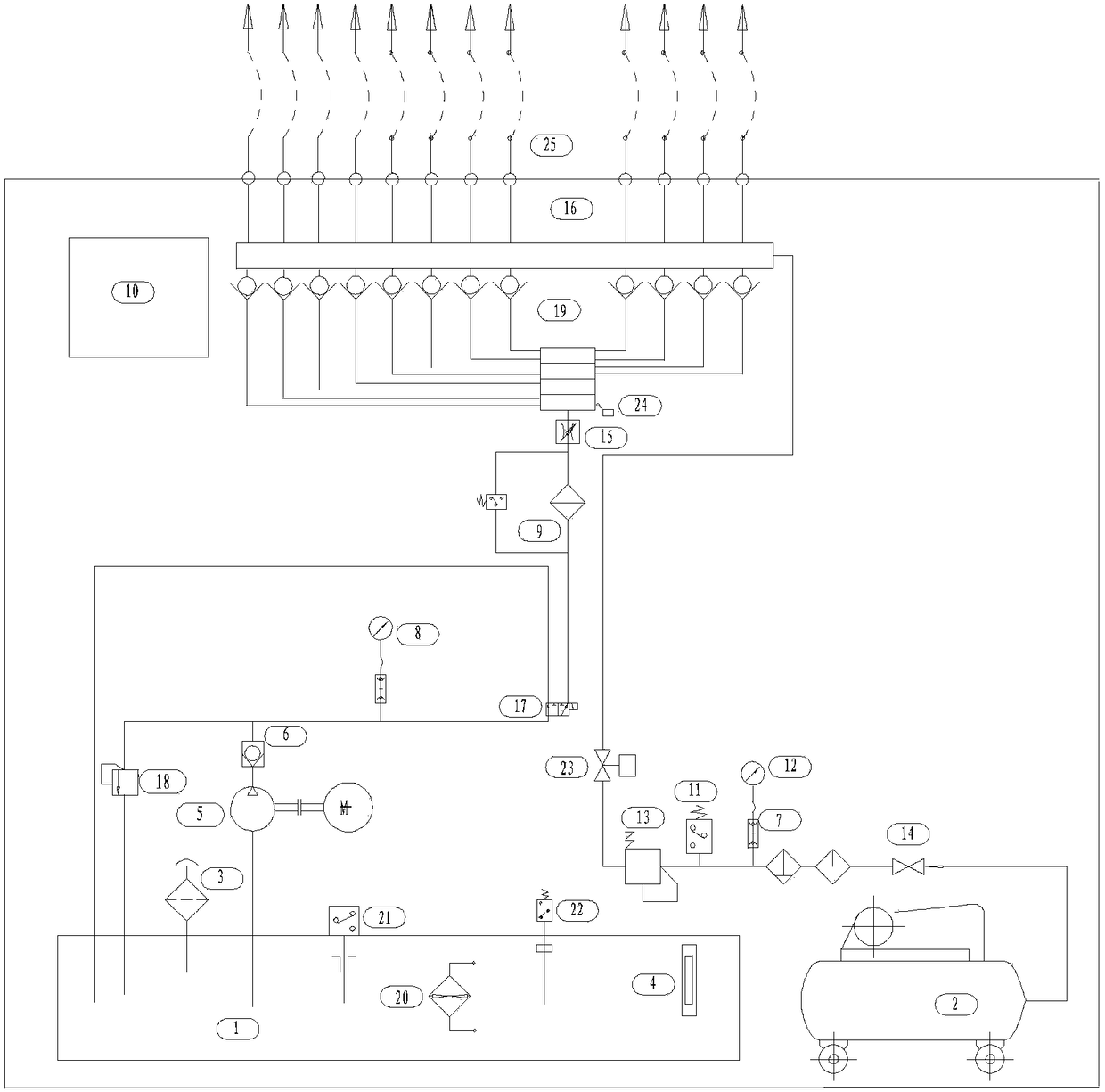

[0022] Attached below figure 1 The present invention is described further:

[0023] A fully automatic lubrication system for the scraper chain of a stacker-reclaimer, comprising a lubricating oil pump 5 connected to a lubricating oil station 1, the lubricating oil station 1 is used to deliver lubricating oil to a progressive distributor 19, and the lubricating oil pump 5 is connected to One-way valve 6, one-way valve 6 is connected with overflow valve 18 and electromagnetic reversing valve 17, electromagnetic reversing valve 17, oil filter 9 and throttle valve 15 are connected in sequence, and throttle valve 15 is connected with progressive distributor 19 , the progressive distributor 19 is used to evenly transport lubricating oil to the oil-air mixer 16, the progressive distributor 19 is connected to the oil-air mixer 16, the oil-air mixer 16 is connected to the lubrication pipeline 25, and the oil-air mixer 16 is connected to the air Compressor 2 or source of compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com