Method for synthesizing ternary precursor without inert gas protection

An inert gas, precursor technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

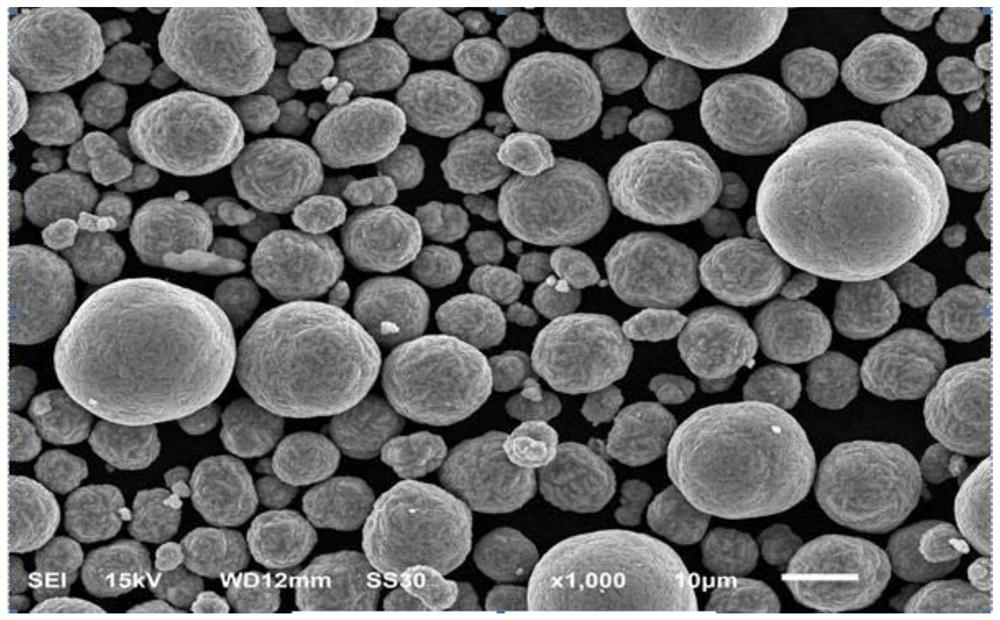

Image

Examples

Embodiment 1

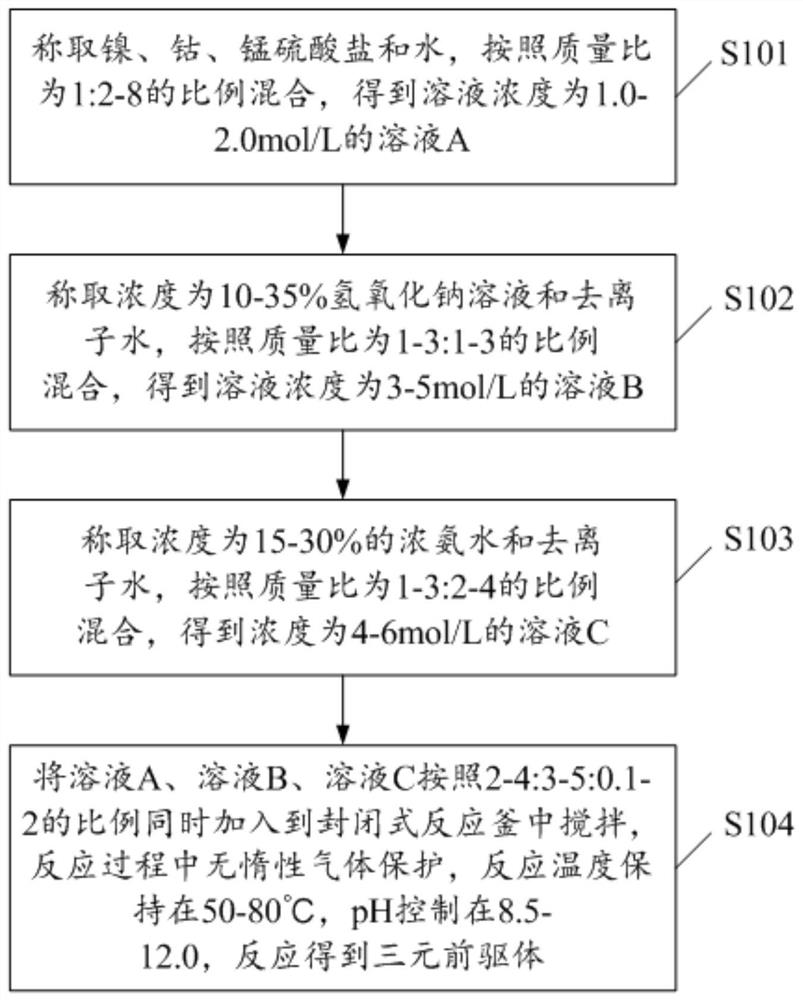

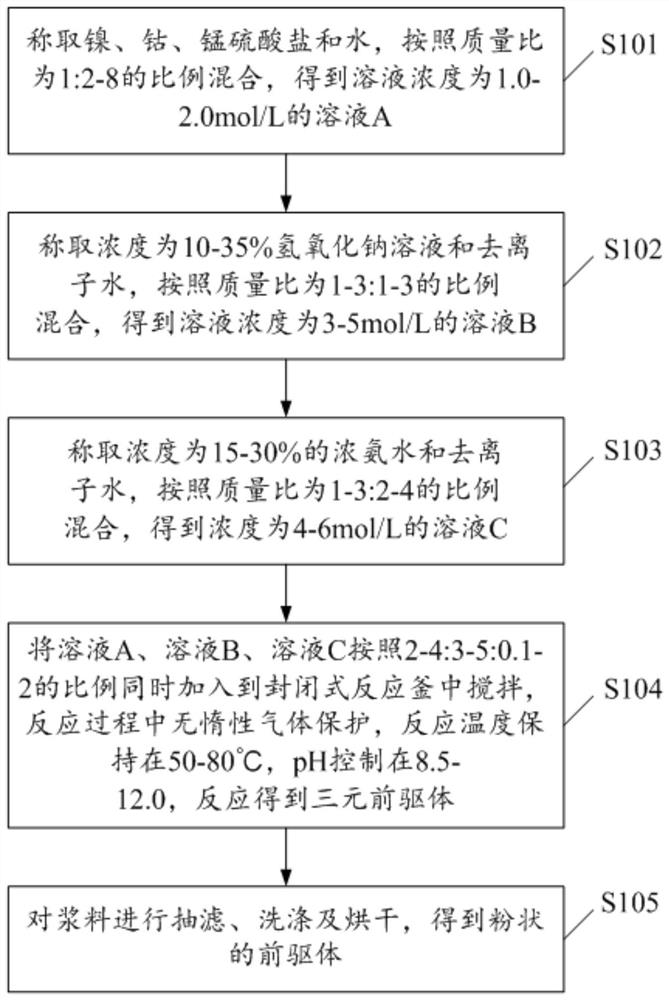

[0054] 1. Weigh 300g of nickel sulfate, 200g of cobalt sulfate, and 50g of manganese sulfate and dissolve them in 1100g of water. After stirring evenly, a solution A with a solution concentration of 1.98mol / L is obtained.

[0055] 2. Weigh 200 g of 15% sodium hydroxide solution and 200 g of deionized water, and stir evenly to obtain solution B with a solution concentration of 3.75 mol / L.

[0056] 3. Weigh 120 g of concentrated ammonia water with a concentration of 25% and 200 g of deionized water to obtain solution C with a solution concentration of 4.28 mol / L.

[0057] 4. Weigh 300g, 400g, and 100g of the above solution A, solution B, and solution C respectively.

[0058] 5. Put solution A, solution B, and solution C into the closed reactor in parallel, and the reaction process does not need nitrogen protection. The stirring rate of the reactor was controlled at 600 rpm / min, the reaction temperature was kept at 50° C., the pH was kept at 9-10, and the reaction time was 40 h....

Embodiment 2

[0061] 1. Weigh 350g of nickel sulfate, 200g of cobalt sulfate, and 60g of manganese sulfate and dissolve them in 2000g of water. After stirring evenly, a solution A with a solution concentration of 1.22mol / L is obtained.

[0062] 2. Weigh 150 g and 200 g of 20% sodium hydroxide solution and 200 g of deionized water, and stir evenly to obtain solution B with a solution concentration of 3.75 mol / L.

[0063] 3. Weigh 120 g of concentrated ammonia water with a concentration of 24% and 200 g of deionized water to obtain solution C with a solution concentration of 4.11 mol / L.

[0064] 4. Weigh 300g, 450g and 100g of the above solution A, solution B and solution C respectively.

[0065] 5. Put solution A, solution B, and solution C into the closed reactor in parallel, and the reaction process does not need nitrogen protection. The stirring rate of the reactor was controlled at 700 rpm / min, the reaction temperature was kept at 60° C., the pH was kept at 9-11, and the reaction time w...

Embodiment 3

[0068] 1. Weigh 320g of nickel sulfate, 250g of cobalt sulfate, and 80g of manganese sulfate and dissolve them in 2000g of water. After stirring evenly, a solution A with a solution concentration of 1.32mol / L is obtained.

[0069] 2. Weigh 200 g of 20% sodium hydroxide solution and 200 g of deionized water, and stir evenly to obtain solution B with a concentration of 5 mol / L.

[0070] 3. Weigh 150 g of concentrated ammonia water with a concentration of 15% and 160 g of deionized water to obtain solution C with a solution concentration of 4.0 mol / L.

[0071] 4. Weigh 350g, 450g, and 150g of the above solution A, solution B, and solution C respectively.

[0072] 5. Put solution A, solution B, and solution C into the closed reactor in parallel, and the reaction process does not need nitrogen protection. The stirring rate of the reactor was controlled at 800 rpm / min, the reaction temperature was kept at 70° C., the pH was kept at 9-10, and the reaction time was 35 hours.

[0073...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com