A method for stabilizing mixed materials in the preparation process of lithium iron phosphate materials

A preparation process, lithium iron phosphate technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of segregation of mixed raw materials, affecting the mixing uniformity of raw materials, high density, etc. The effect of pulp scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

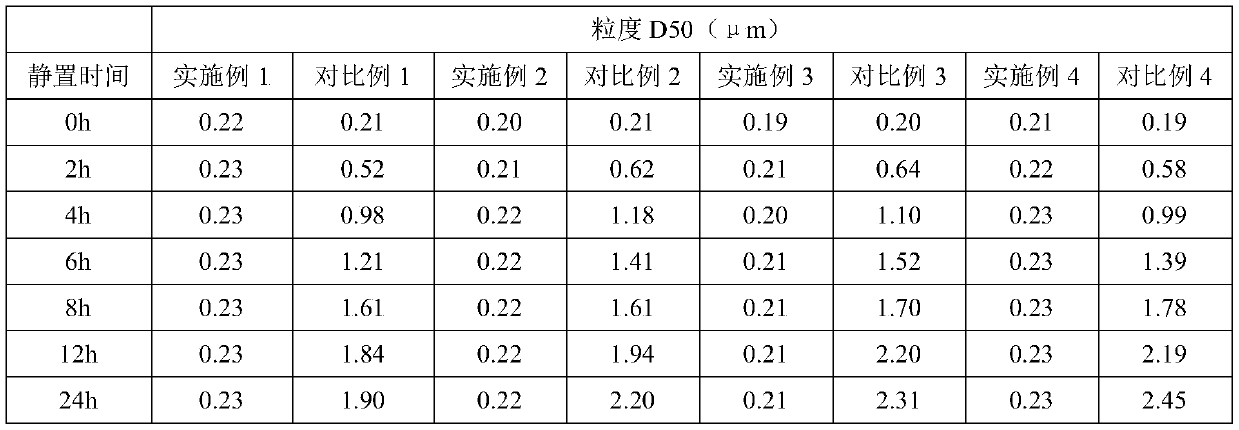

Examples

Embodiment 1

[0022] A method for stabilizing mixed materials during the preparation of lithium iron phosphate materials, comprising the following steps:

[0023] (1) Weigh lithium hydroxide, ferric oxide and phosphoric acid according to the stoichiometric ratio Li:Fe:P=1:1:1. Take by weighing carbon source by ferric oxide: carbon source=1:0.05 weight ratio, wherein carbon source uses carbon black.

[0024] (2) Add 60 parts of deionized water in the mixing tank, then add 40 parts of lithium hydroxide, ferric oxide, phosphoric acid and carbon source weighed according to the proportion of step (1);

[0025] (3) Stir the materials such as lithium oxide, ferric oxide, phosphoric acid and carbon source in the stirring tank for 1.5h under the speed condition of the linear speed of 8m / s;

[0026] (4) After completing step 3, add guar gum and xanthan gum in the mixing tank (the ratio of guar gum and xanthan gum is 1:1, and the addition amount is that both guar gum and xanthan gum are 0.4% of the ...

Embodiment 2

[0030] A method for stabilizing mixed materials during the preparation of lithium iron phosphate materials, comprising the following steps:

[0031] (1) Weigh lithium hydroxide, ferric oxide and phosphoric acid according to the stoichiometric ratio Li:Fe:P=1:0.98:1. The carbon source is weighed in the weight ratio of ferric oxide: carbon source=1:0.1, wherein the carbon source uses glucose.

[0032] (2) Add 65 parts of deionized water in the mixing tank, then add 35 parts of lithium hydroxide, ferric oxide, phosphoric acid and carbon source weighed according to the proportion of step (1);

[0033] (3) Stir the materials such as lithium oxide, ferric oxide, phosphoric acid and carbon source in the mixing tank for 1 hour at a speed condition of a cutter head type stirring paddle at a linear speed of 9 m / s;

[0034] (4) After completing step 3, add guar gum and xanthan gum in the mixing tank (the ratio of guar gum and xanthan gum is 1:1, and the addition amount is that both guar...

Embodiment 3

[0038] A method for stabilizing mixed materials during the preparation of lithium iron phosphate materials, comprising the following steps:

[0039] (1) Lithium hydroxide, ferric oxide and phosphoric acid were weighed according to the stoichiometric ratio Li:Fe:P=1:0.99:0.99. The carbon source is weighed in the weight ratio of ferric oxide: carbon source=1:0.08, wherein the carbon source uses sucrose.

[0040] (2) Add 70 parts of deionized water in the mixing tank, then add 30 parts of lithium hydroxide, ferric oxide, phosphoric acid and carbon source weighed according to the proportion of step (1);

[0041] (3) Stir the materials such as lithium oxide, ferric oxide, phosphoric acid and carbon source in the stirring tank for 1 hour under the speed condition of the linear velocity of 10m / s with the cutterhead type stirring paddle;

[0042] (4) After completing step 3, add guar gum and xanthan gum (the ratio of guar gum and xanthan gum is 2:1, and the amount of addition is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com