High porosity porous ceramic microsphere and preparation method thereof

A technology of porous ceramics and high porosity, applied in the field of materials, can solve the problems that it is difficult to meet the requirements of performance, efficiency, economy and environmental protection at the same time, it is difficult to prepare millimeter-scale ceramic microspheres, and the price of organic templates is expensive, so as to achieve low cost , Conducive to industrial production, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

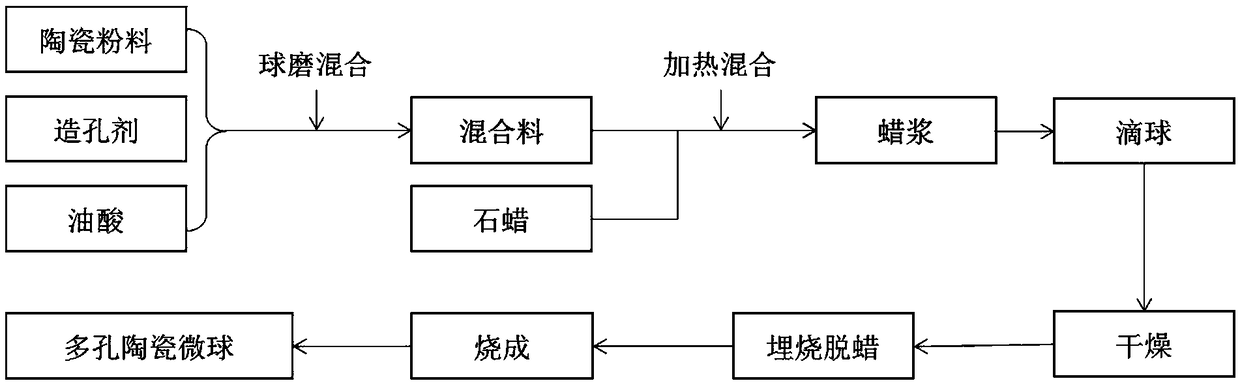

[0033] A method for preparing porous alumina ceramic microspheres with high porosity in this embodiment, the method comprises the following steps:

[0034] (1) Weigh alumina (Al 2 o 3 ) Ceramic powder, carbon powder and oleic acid, the three are mixed uniformly, and the mixture is obtained through a 100-mesh sieve after ball milling;

[0035] (2) Mix the mixture prepared in step (1) with paraffin wax at a ratio of 100:15, and then stir evenly at a temperature of 120° C. to obtain a wax slurry;

[0036] (3) Continue heating the wax slurry prepared in step (2) to 130° C., and then drop the wax slurry dropwise into water at 40° C. using a No. 6 syringe needle to solidify into balls to obtain solidified microspheres;

[0037] (4) Embed the solidified microspheres prepared in step (3) into alumina powder, place them in a muffle furnace at room temperature, and heat up to 900°C at a heating rate of 1°C / min to remove wax and keep warm Cool to room temperature after 30 minutes to o...

Embodiment 2

[0041] A method for preparing porous zirconia ceramic microspheres with high porosity in this embodiment, the method includes the following steps:

[0042] (1) Weigh zirconia (ZrO 2 ) ceramic powder and acetylene black, the two are mixed uniformly, and after ball milling, cross a 100-mesh sieve to obtain the mixture;

[0043] (2) Mix the mixture prepared in step (1) with paraffin wax in a ratio of 100:10, and then stir evenly at a temperature of 120° C. to obtain a wax slurry;

[0044] (3) Continue heating the wax slurry prepared in step (2) to 155° C., and then drop the wax slurry into water at 25° C. to solidify into balls using a No. 6 syringe needle to obtain solidified microspheres;

[0045] (4) Embed the solidified microspheres prepared in step (3) into zirconia powder, place them in a muffle furnace at room temperature, heat up to 1150°C at a heating rate of 1°C / min to remove wax, and keep warm for 30min After cooling to room temperature, bisque fired zirconia ceramic...

Embodiment 3

[0049] A kind of preparation method of high porosity porous magnesia ceramic microsphere of the present embodiment, described method comprises the following steps:

[0050] (1) Weigh magnesium oxide (MgO) ceramic powder, starch and oleic acid respectively according to the weight ratio of 75:25:1, mix the three evenly, and pass through a 100-mesh sieve after ball milling to obtain the mixture;

[0051] (2) Mix the mixture prepared in step (1) with paraffin wax in a ratio of 100:40, and then stir evenly at a temperature of 95° C. to obtain a wax slurry;

[0052] (3) Continue heating the wax slurry prepared in step (2) to 135°C, and then use a No. 5 syringe needle to drop the wax slurry into silicone oil at 35°C to solidify into balls to obtain solidified microspheres ;

[0053] (4) Embed the solidified microspheres prepared in step (3) into magnesium oxide powder, place in a muffle furnace at room temperature, heat up to 950°C at a heating rate of 1°C / min to remove wax, and kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com