In-situ nitrogen-doped porous core-shell-structured carbon/selenium composite material, and preparation method and application thereof

A technology of porous carbon materials and composite positive electrode materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of large volume changes of positive and negative electrode materials, unfavorable charge transfer, low Coulombic efficiency, etc., to improve electrochemical performance , raw materials and equipment are simple, and the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

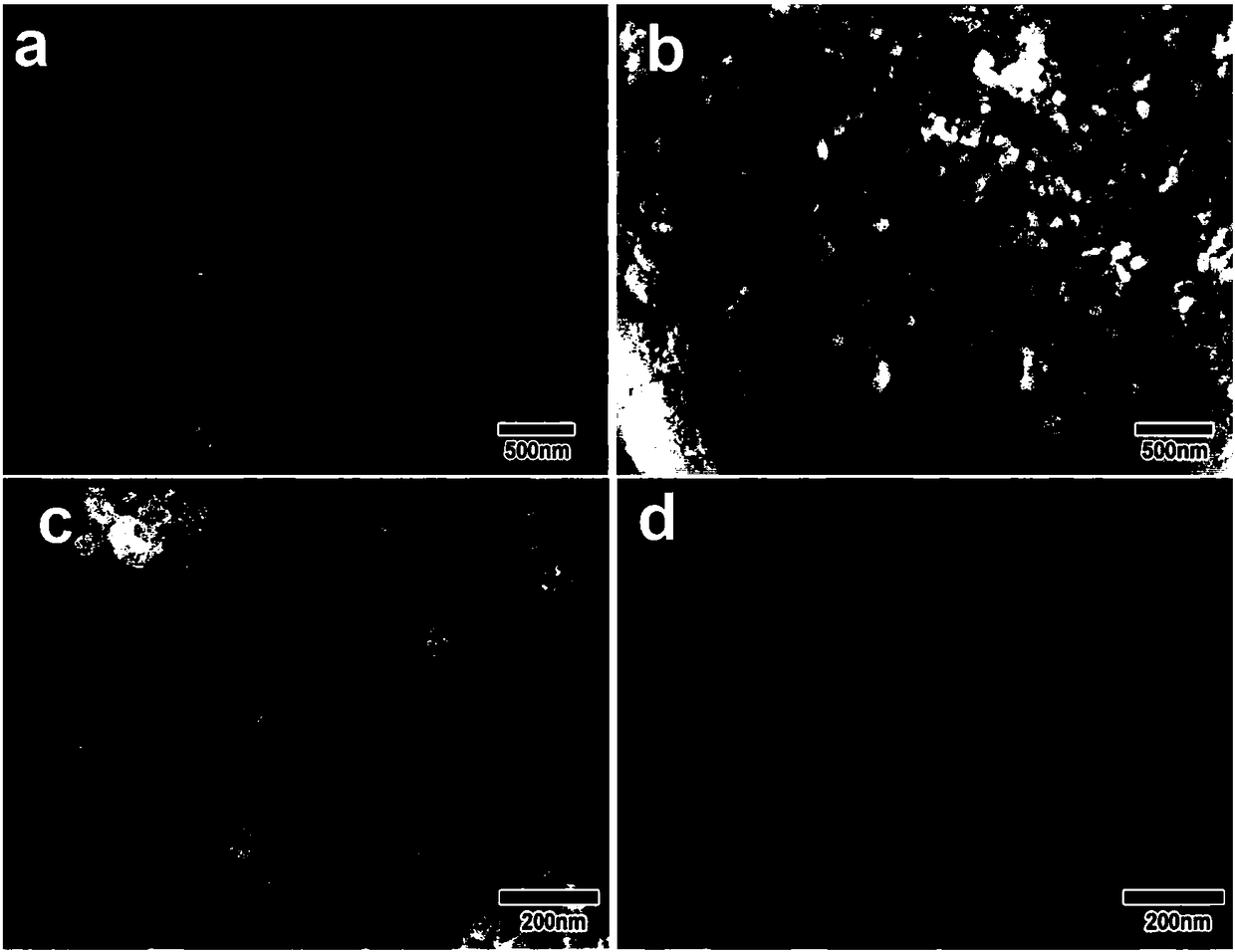

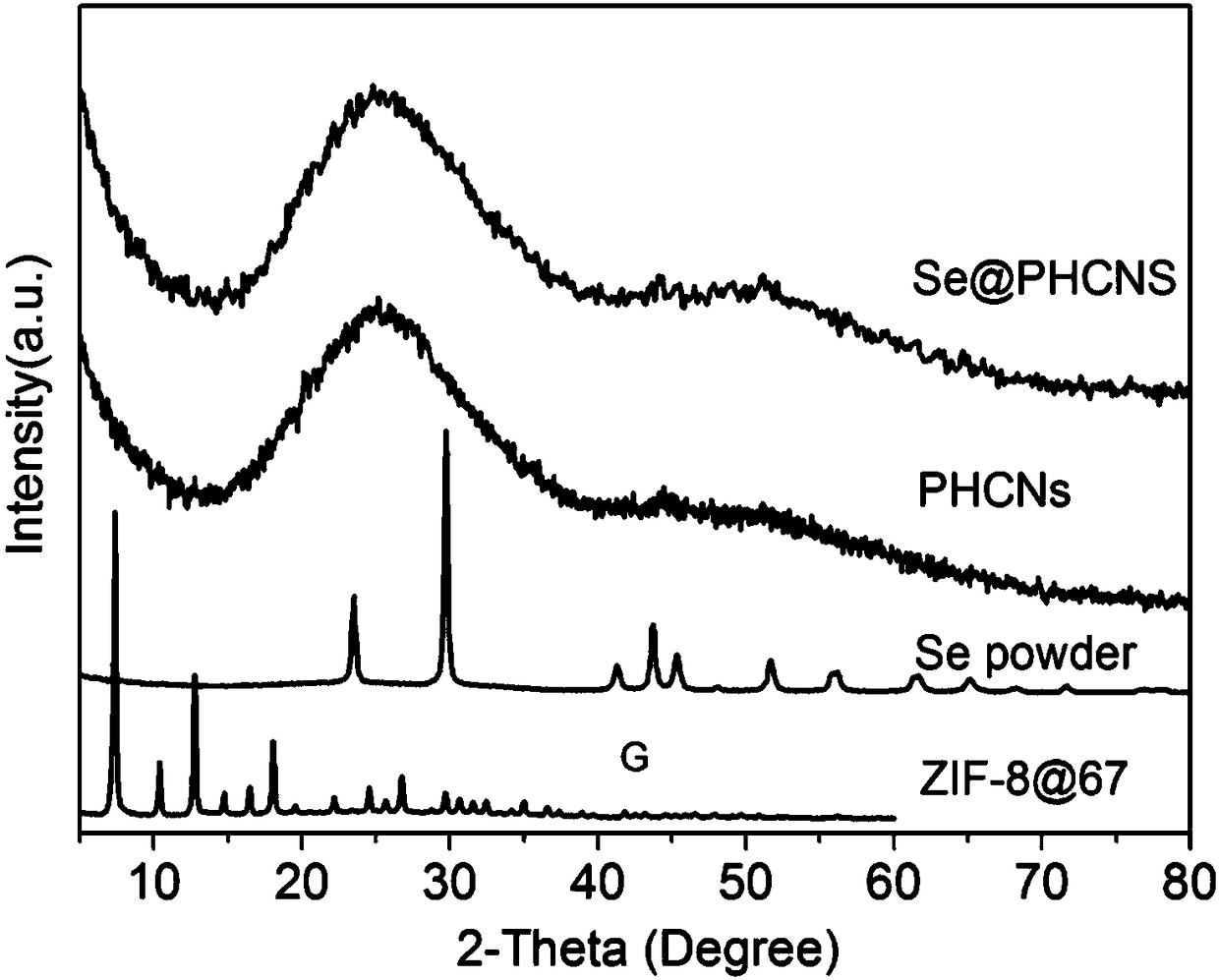

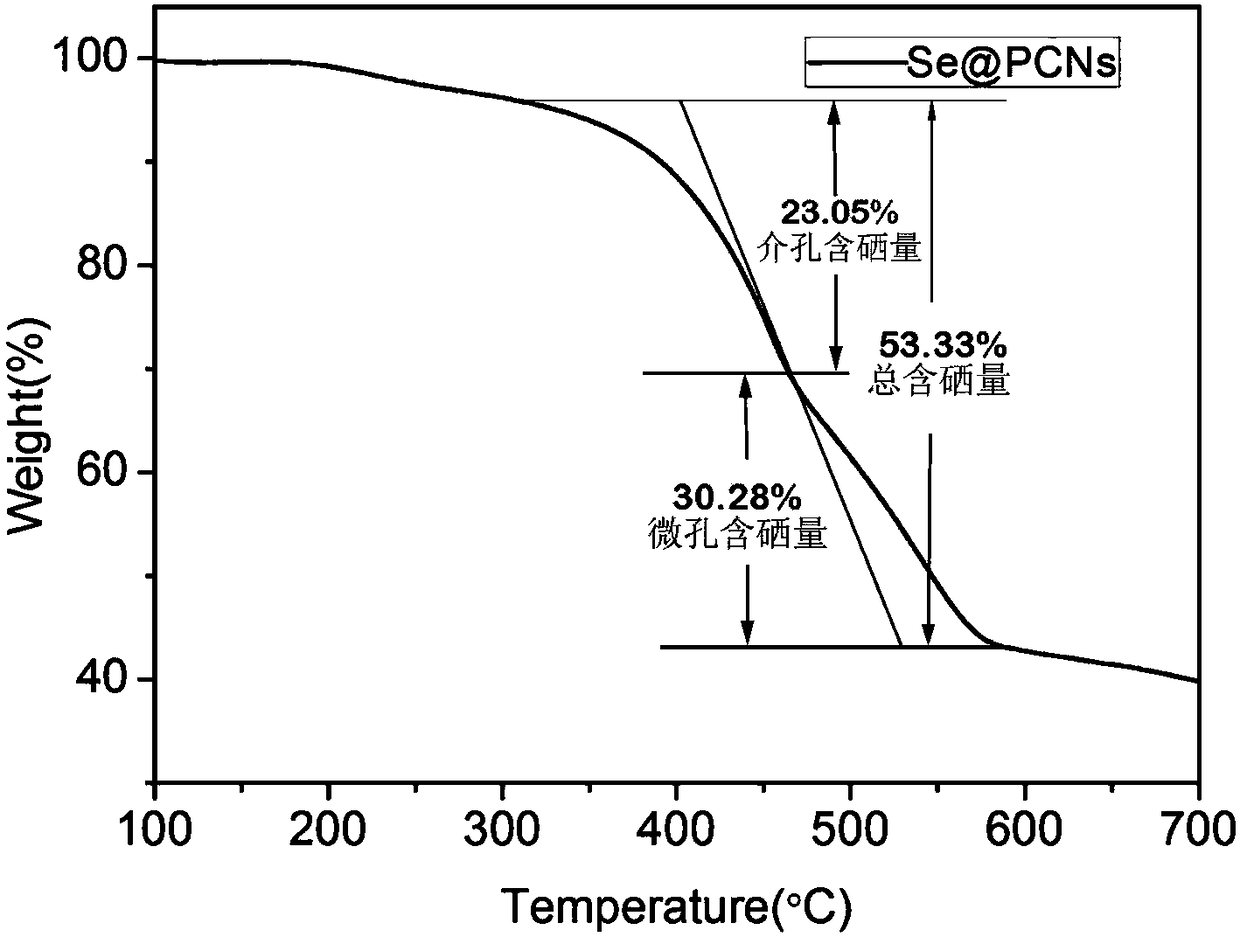

[0038] An in-situ nitrogen-doped porous core-shell structure carbon / selenium composite positive electrode material, the preparation method of which comprises the following steps:

[0039] 1) Dissolve 2.933g of zinc nitrate hexahydrate in 200mL of methanol to obtain solution A; dissolve 6.589g of dimethylimidazole in 100ml of methanol to obtain solution B; add 2.9103g of cobalt nitrate hexahydrate to 100ml of methanol to obtain solution C. Under room temperature condition, solution A is mixed with solution B rapidly, and the stirring reaction time is 1.5 hours (stirring speed is 50 revs / min), then adds solution C, continues to react under normal temperature stirring condition 1.5 hours (stirring speed is 60 revs / min) min); after the reaction, the product was centrifuged and washed with absolute ethanol (8000 rpm) three times, and the precipitate obtained by centrifugation was placed in a vacuum drying oven and dried at 60°C for 24 hours to obtain a core-shell structure ZIF- 8@Z...

Embodiment 2

[0053] An in-situ nitrogen-doped porous core-shell structure carbon / selenium composite positive electrode material, the preparation method of which comprises the following steps:

[0054] 1) Dissolve 2.933g of zinc nitrate hexahydrate in 50mL of methanol to obtain solution A; dissolve 6.589g of dimethylimidazole in 100ml of methanol to obtain solution B; add 2.9103g of cobalt nitrate hexahydrate to 50ml of methanol to obtain solution C. Mix solution A and solution B under rapid conditions, stirring reaction time is 1 hour (stirring rate is 50 rpm), then add solution C, continue to react at room temperature for 1 hour (stirring rate is 70 rpm) After the reaction, the product was centrifuged and washed with absolute ethanol (8000 rpm) three times, and the precipitate obtained by centrifugation was placed in a vacuum drying oven and dried at 60°C for 24 hours to obtain ZIF-8@ with a core-shell structure. ZIF-67 particles, collected for later use;

[0055] 2) Place the product ob...

Embodiment 3

[0059] An in-situ nitrogen-doped porous core-shell structure carbon / selenium composite positive electrode material, the preparation method of which comprises the following steps:

[0060] 1) Dissolve 2.933g of zinc nitrate hexahydrate in 100mL of methanol to obtain solution A; dissolve 6.589g of dimethylimidazole in 200ml of methanol to obtain solution B; add 0.5821g of hexahydrate of cobalt nitrate to 100ml of methanol to obtain solution C. Mix solution A and solution B under rapid conditions, and the stirring reaction time is 1 hour (stirring speed is 60 revolutions / min), then add solution C, and continue to react under normal temperature stirring conditions for 1 hour (stirring speed is 70 revolutions / min) After the reaction, the product was centrifuged and washed with absolute ethanol (8000 rpm) three times, and the precipitate obtained by centrifugation was placed in a vacuum drying oven and dried at 40°C for 36 hours to obtain ZIF-8@ with a core-shell structure. ZIF-67 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com