Preparation method for refined material of crude trimesic acid

A technology of trimellitic acid and crude homogenization, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, alkali metal oxides/hydroxides, etc., can solve the problem of high energy consumption, poor adsorption capacity, long time consumption, etc. problem, to achieve the effect of long service life, good corrosion resistance and reduced time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

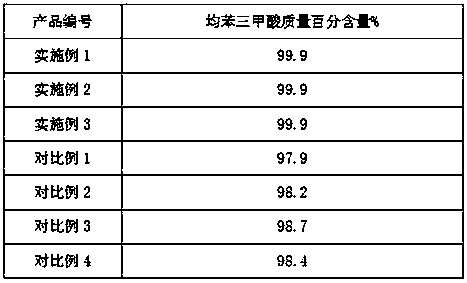

Examples

Embodiment 1

[0022] In the reaction kettle, add maleic anhydride 100Kg, polyvinyl alcohol 1.5Kg, 1,5,9,13-tetradetracene 2Kg, 3-isoamyl (2-methyl-3-furyl) Disulfide 0.75Kg, furan-3-ylethynyl trimethylsilane 1.5Kg, N-hydroxyl-5-norbornene-2,3-dicarboximide perfluorobutyl sulfonate 0.5Kg, ( 2Z)-cyano-3-hydroxy-N-[4-(trifluoromethyl)phenyl]-2-butenamide 0.05Kg, benzoyl peroxide 1.5Kg, liquid wax 40Kg, water 750Kg, stir well Afterwards, the temperature was raised to 87°C, and the reaction was carried out for 15 hours. After the reaction, the liquid wax was washed away with gasoline, washed with water, and dried to obtain the refined material of crude trimesic acid.

Embodiment 2

[0024] In the reaction kettle, add maleic anhydride 100Kg, polyvinyl alcohol 1Kg, 1,5,9,13-tetradetracene 1Kg, 3-isoamyl (2-methyl-3-furyl) di Thioethers 0.5Kg, furan-3-ylethynyltrimethylsilane 1Kg, N-hydroxy-5-norbornene-2,3-dicarboximide perfluorobutylsulfonate 0.1Kg, (2Z) -cyano-3-hydroxyl-N-[4-(trifluoromethyl)phenyl]-2-butenamide 0.01Kg, benzoyl peroxide 1Kg, liquid wax 30Kg, water 500Kg, stir and heat up to React at 80°C for 10 hours. After the reaction, wash off the liquid wax with gasoline, wash with water, and dry to obtain the refined material of crude trimesic acid.

Embodiment 3

[0026] In the reaction kettle, add maleic anhydride 100Kg, polyvinyl alcohol 2Kg, 1,5,9,13-tetradetracene 3Kg, 3-isoamyl (2-methyl-3-furyl) di Sulfide 1Kg, furan-3-ylethynyltrimethylsilane 2Kg, N-hydroxy-5-norbornene-2,3-dicarboximide perfluorobutylsulfonate 1Kg, (2Z)-cyanide Base-3-hydroxy-N-[4-(trifluoromethyl)phenyl]-2-butenamide 0.1Kg, benzoyl peroxide 2Kg, liquid wax 50Kg, water 1000Kg, stir well and heat up to 95°C , React for 20h, after the reaction, wash off the liquid wax with gasoline, wash with water, and dry to obtain the refined material of crude trimesic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com