An equipment for batch production of lanthanum calcium manganese oxide powder

A technology for mass production of lanthanum calcium manganese oxide powder, applied in the field of ceramic powder equipment, can solve the problems of complexity, less powder, more equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

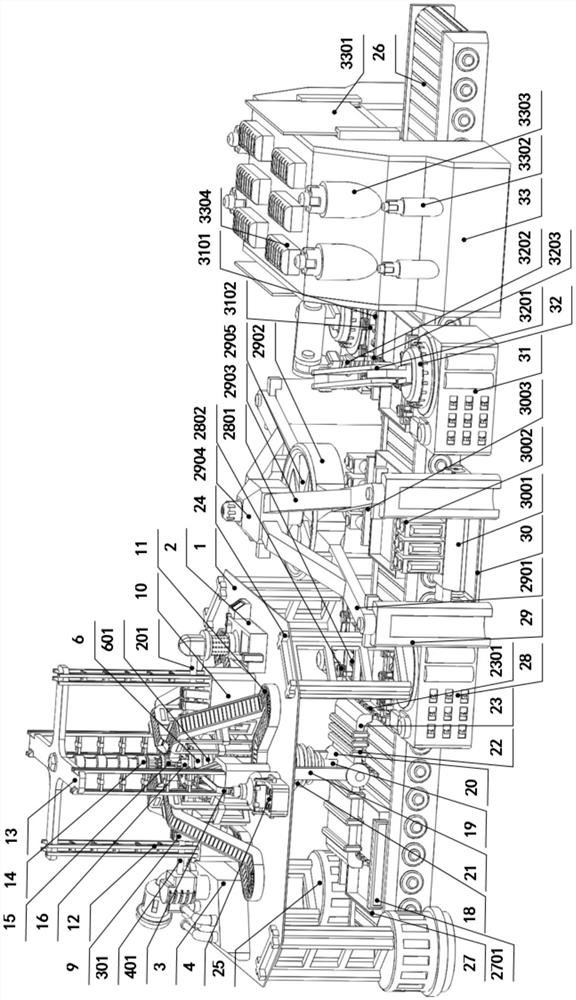

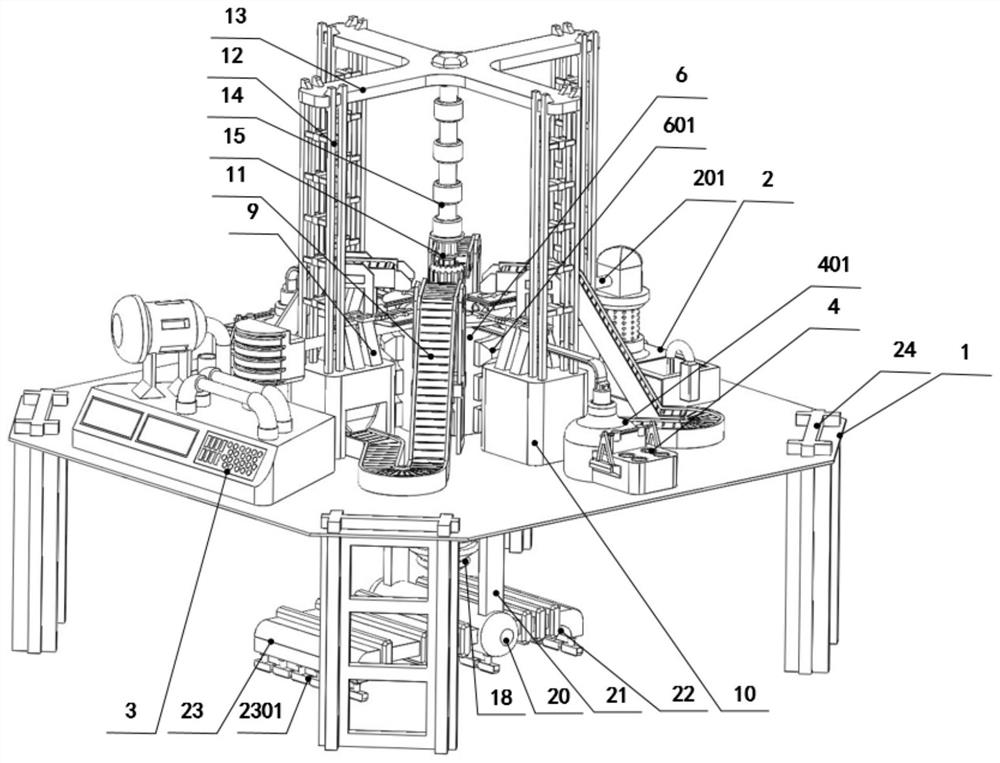

[0045] Embodiment 1: as Figure 1~5 As shown, an equipment for mass production of lanthanum calcium manganese oxide powder, including a work frame system, a sol system, a gel system, a drying system, a crushing system, a sintering system, a transmission system, a work frame system, a drying system, a crushing The system and the sintering system are set on the same level in turn, the sol system is fixed on the work frame system, the gel system is set under the work frame system, the gel system is connected to one end of the transmission system, and the other end of the transmission system passes through the work frame system in turn. Rack system, drying system, crushing system, sintering system;

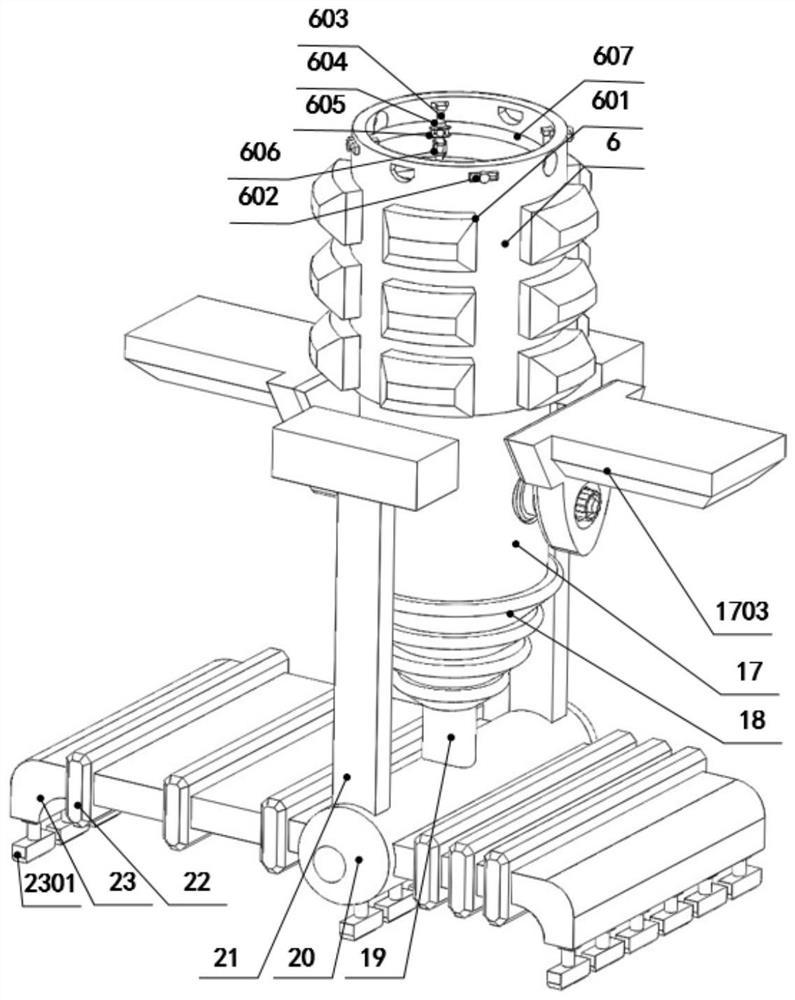

[0046]The sol system includes solvent control machine 2, air pressure control machine 3, acid machine 4, lye machine 5, sol tank body 6, wall heater 601, signal transmitter 602, signal tube 603, water level detector 604, liquid temperature detection Device 605, pH detector 606, spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com