Ferroelectric polymer electric card material and preparation method thereof

A ferroelectric polymer, electric card technology, applied in electrolytic coatings, manufacturing/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the refrigeration power of electric card devices. The problems of low density, difficult heat conduction of electric card materials, and low electric card strength can achieve the effect of improving the strength of electric cards, solving heat conduction difficulties, and improving the strength of electric cards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

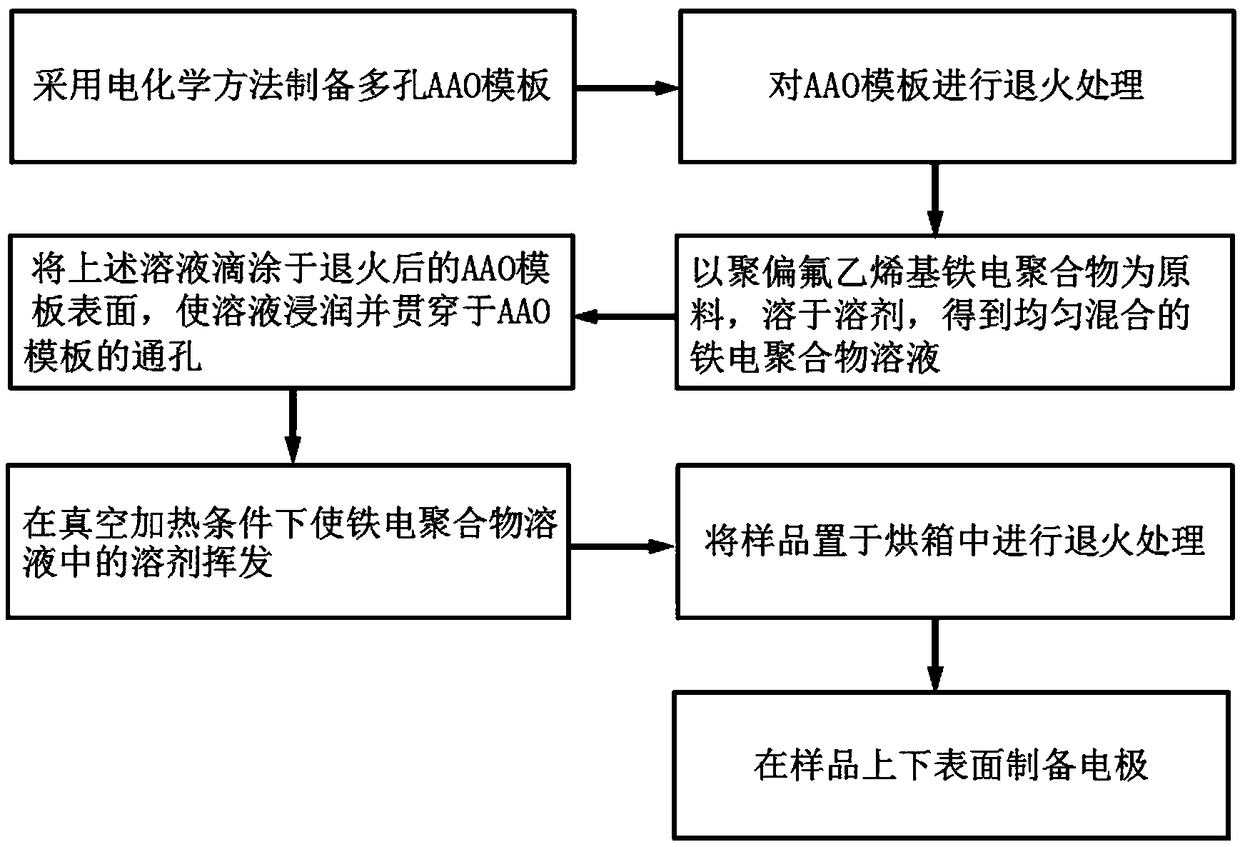

[0046] A. Preparation of porous AAO template, the specific steps are as follows:

[0047] a. Anneal the aluminum foil at 400 degrees Celsius, and the holding time is 2 hours, which is conducive to the subsequent formation of a regular pore structure;

[0048] b. Ultrasonic cleaning of aluminum foil in toluene and ethanol for 10 minutes;

[0049] c. Using the steel plate as the cathode and the aluminum foil as the anode, perform electrochemical polishing in a solution with a volume ratio of perchloric acid and ethanol of 1:4, with a voltage of 20V;

[0050] d. Carry out one oxidation in 0.3mol / L oxalic acid with the polished aluminum foil as the anode and the steel plate as the cathode, the voltage is 60V, and the time is 1 hour;

[0051] e. Soak the aluminum foil after the primary oxidation in a mixed solution of 6wt% phosphoric acid and 1.8wt% chromic acid, place it in an oven at 80 degrees Celsius to remove the surface aluminum oxide formed by the primary oxidation, and the...

Embodiment 2

[0061] In step A, the primary oxidation voltage is 25V, and the reaction time is 6 hours; the secondary oxidation voltage is 25V, and the reaction time is 20 hours, and the rest are the same as in Example 1.

Embodiment 3

[0063] In step A, the electrochemical reaction solution is 0.3mol / L phosphoric acid solution, the primary oxidation voltage is 195V, and the reaction time is 6 hours; the secondary oxidation voltage is 195V, and the reaction time is 20 hours, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com