Surgical instrument two-cavity multienzyme coagulated bead and preparation method thereof

A technique for surgical instruments and coagulation beads, which is applied in the field of surgical instrument two-cavity multi-enzyme coagulation beads and its preparation, can solve the problems of decreased enzyme activity stability and cleaning power of cleaning agents, etc., and achieves the goal of maintaining enzyme activity and being easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

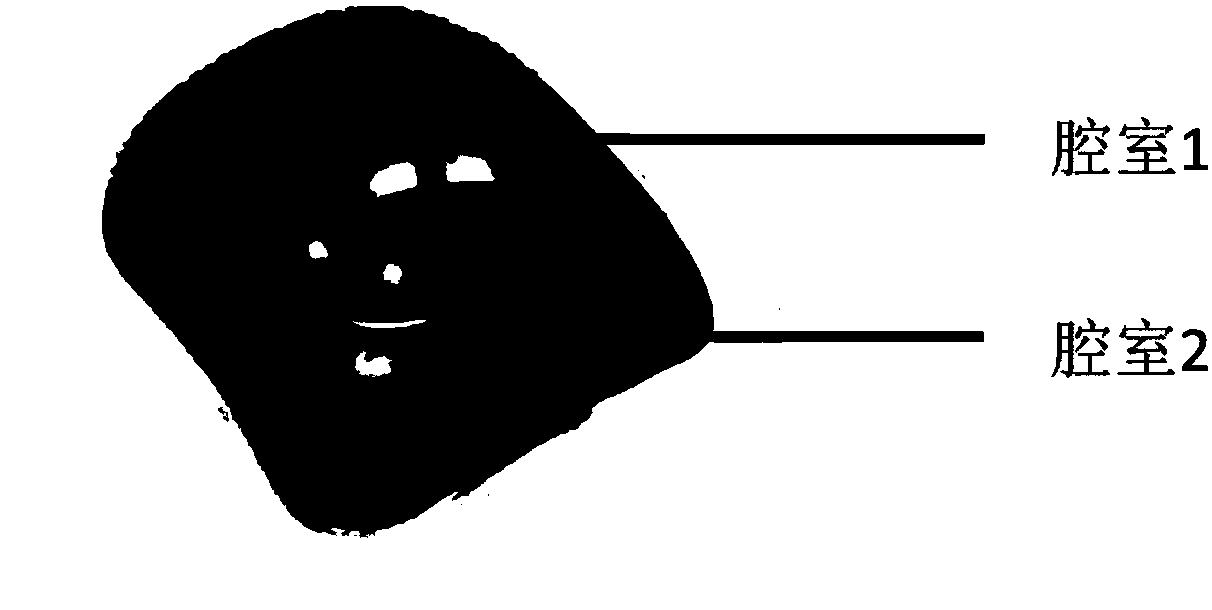

[0033] Example 1: The structure of the two-chamber multi-enzyme coagulation beads for surgical instruments and instructions for use

[0034] The two-chamber multi-enzyme coagulation bead of the surgical instrument uses a water-soluble polymer film as a coating material to make a coagulation bead with two chambers. The two-chamber beads contain solid enzyme in one chamber and anhydrous ultra-concentrated cleaning agent in the other chamber. The polymer film is preferably one or both of polyvinyl alcohol, polyvinylpyrrolidone and cellulose;

[0035] The ultra-concentrated cleaning agent is composed of the following components and the mass percentages of each component are:

[0036] Nonionic surfactant: 30%~80%

[0037] Amphoteric surfactant: 2%~10%

[0038] Corrosion inhibitor: 2%~15%

[0039] Chelating agent: 0.1%~2%

[0040] Fungicide: 1%~10%

[0041] Solvent balance

[0042] The total is 100%.

[0043] The non-surfactant is two or more of fatty alcohol polyoxyethylene...

Embodiment 2

[0055] Example 2 Preparation method of two-chamber multi-enzyme beads for surgical instruments

[0056] The ultra-concentrated cleaning agent is composed of the following components and the mass percentages of each component are:

[0057] AEO-9: 80%

[0058] Crodateric PI: 2%

[0059] Crodacor BE: 2%

[0060] Glutamate diacetate tetrasodium salt: 2%

[0061] Casson: 1%

[0062] polyethylene glycol balance

[0063] The total is 100%.

[0064] Add part of polyethylene glycol into the stirred tank according to the formula proportion, turn on the stirrer, first add 2% amphoteric surfactant imidazoline amphoteric surfactant Crodateric PI, then add 2% chelating agent glutamic acid diacetic acid tetrasodium salt to dissolve After the dissolution is completed, add 80% nonionic surfactant fatty alcohol polyoxyethylene ether AEO-9, 1% fungicide Cassone, 2% corrosion inhibitor organic borate Crodacor BE, and then add the remaining amount of solvent polyethylene alcohol, and then s...

Embodiment 3

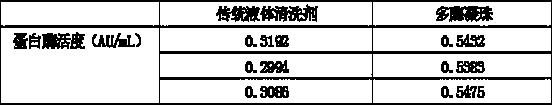

[0080] The two-chamber multi-enzyme beads of the above surgical instruments and the traditional liquid multi-enzyme cleaning agent on the market were evaluated in the protease activity, and the results are shown in the following table.

[0081]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com