Method for preparing chrome tanning agent from leather-making chromium-containing waste

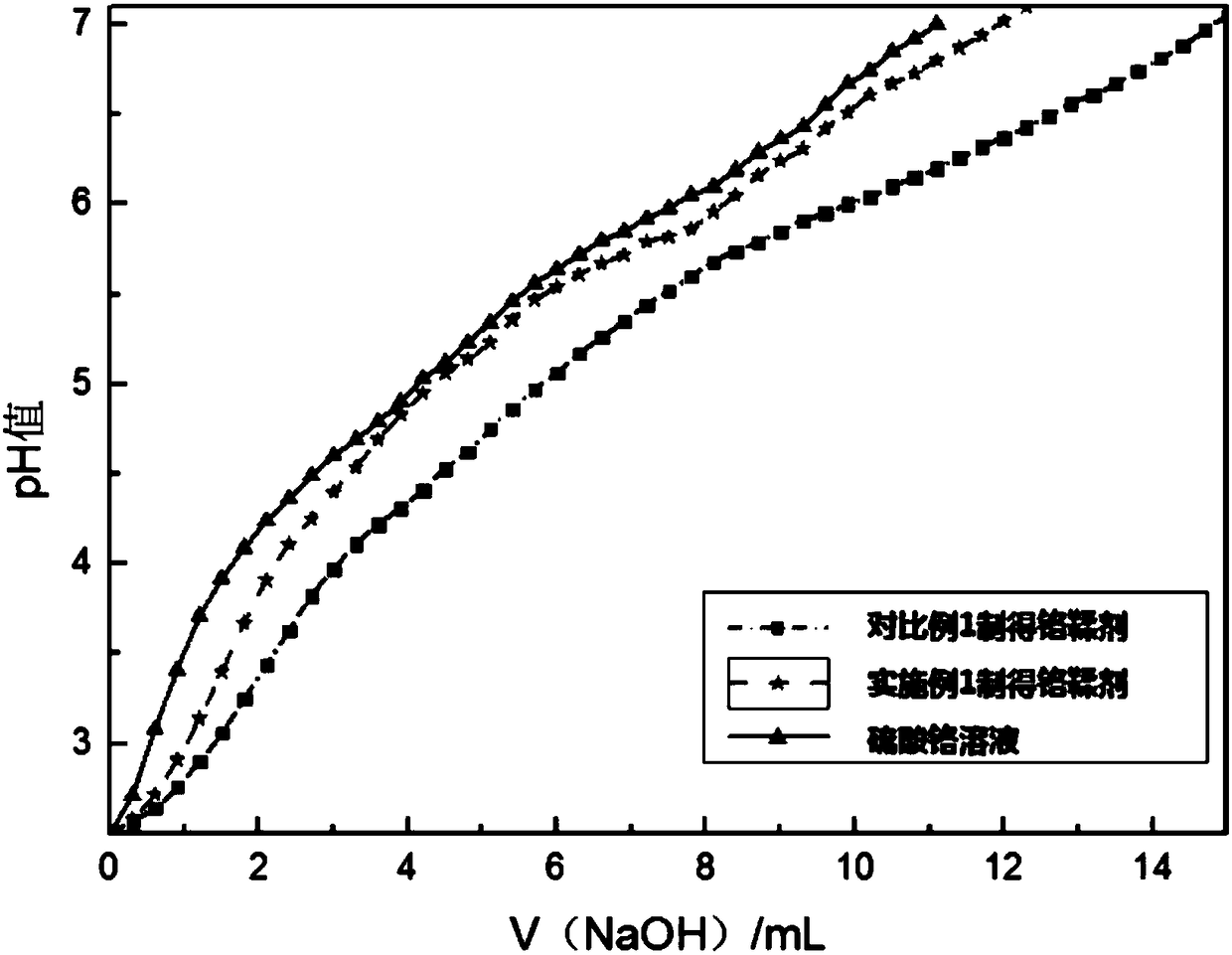

A chrome tanning agent and waste technology, applied in the field of preparing chrome tanning agent, can solve the problems of incomplete recovery of chrome resources, poor chrome tanning performance, low utilization rate, etc., achieve a suitable complexation degree, improve alkali resistance and The effect of stability and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method that this implementation utilizes tanning chromium-containing waste to prepare chrome tanning agent is as follows:

[0046] 1. Pretreatment

[0047] A1. Mix tanning chromium-containing waste skin residue with water, then add calcium oxide and sodium hydroxide, stir and hydrolyze at 65°C for 6 hours, after the reaction time is up, adjust the pH to 7, and let it stand at 30°C 1h, the precipitate was separated; wherein, by mass, the chromium-containing waste leather residue: water: calcium oxide: sodium hydroxide = 100:500:10:1;

[0048] B1. mixing the precipitate obtained in step A1 with water so that the water content reaches 95%, to obtain 95% chrome sludge;

[0049] C1. Add alkaline protease to the chrome sludge obtained in step B1, stir and hydrolyze for 4 hours at 50° C., and obtain chromium cake after solid-liquid separation; wherein, the mass of the chromium sludge: mass of alkaline protease = 100:2;

[0050] D1. stirring and washing the chromium cake ...

Embodiment 2

[0059] The method that this implementation utilizes tanning chromium-containing waste to prepare chrome tanning agent is as follows:

[0060] 1. Pretreatment

[0061] A1. Mix tanning chromium-containing waste skin residue with water, then add calcium oxide and sodium hydroxide, stir and hydrolyze at 65°C for 5 hours, after the reaction time is up, adjust the pH to 7.5, and let it stand at 35°C 1h, the precipitate was separated; wherein, by mass, the tannery chromium-containing waste skin residue: water: calcium oxide: sodium hydroxide = 100: 500: 9: 1.5;

[0062] B1. mixing the precipitate obtained in step A1 with water so that the water content reaches 92%, to obtain the chrome sludge with a water content of 92%;

[0063] C1. Add alkaline protease to the chromium sludge obtained in step B1, stir and hydrolyze for 4 hours at 50° C., and obtain chromium cake after solid-liquid separation; wherein, the mass of the chromium sludge: mass of alkaline protease = 100: 2.5;

[0064]...

Embodiment 3

[0068] The method that this implementation utilizes tanning chromium-containing waste to prepare chrome tanning agent is as follows:

[0069] 1. Pretreatment

[0070] A1. Mix tannery chromium-containing waste skin residue with water, then add calcium oxide and sodium hydroxide, stir and hydrolyze at 65°C for 6 hours, after the reaction time is up, adjust the pH to 8, and let it stand at 40°C 1h, the precipitate was separated; wherein, by mass, the chromium-containing waste leather slag: water: calcium oxide: sodium hydroxide = 100:400:8:1;

[0071] B1. mixing the precipitate obtained in step A1 with water so that the water content reaches 89%, to obtain chrome sludge with a water content of 89%;

[0072] C1. Add alkaline protease to the chrome sludge obtained in step B1, stir and hydrolyze for 4 hours at 50° C., and obtain chromium cake after solid-liquid separation; wherein, the mass of the chromium sludge: mass of alkaline protease = 100:3;

[0073] D1. stirring and washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com