Direct heat-supply system adopting mine water waste heat

A heating system, mine water technology, applied in the direction of boreholes/well components, isolation devices, earthwork drilling and mining, etc., can solve the problems of polluting the surrounding environment, poor heating load capacity, large amounts of waste water, waste gas and solid waste, etc. To achieve the effect of practical system and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

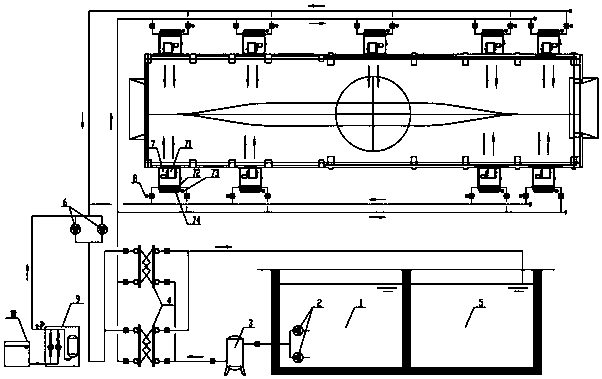

[0012] A mine water waste heat direct heating system such as figure 1 shown. The system includes two parts: water system and wind system.

[0013] The water system is divided into heat source side and heat supply side.

[0014] The heat source side of the water system includes a mine water supply pool 1, a submersible sewage pump 2, a quartz sand filter 3, a plate heat exchanger 4, and a mine water return pool 5. The mine water supply pool 1 stores the preliminarily treated high-temperature mine water, and at the same time precipitates larger particles in the mine water. The temperature of the high-temperature mine water in the mine water supply pool 1 is between 20°C and 35°C. The submersible sewage pump 2 is installed in the mine water supply pool 1, and the high-temperature mine water is transported through the submersible sewage pump 2 and first enters the quartz sand filter 3. The quartz sand filter 3 filters the mine water. The impurities in the mine water are filtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com