A kind of conductive titanium oxide ceramic sputtering target material and preparation method thereof

A titanium oxide and target technology, which is applied in the field of conductive titanium oxide ceramic sputtering targets and their preparation, can solve the problems of low sputtering efficiency, high product production cost, affecting target performance and density uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The invention provides a method for preparing a titanium oxide target, comprising the following steps:

[0069] 1) Provide modified titanium oxide nanopowder;

[0070] 2) compressing the modified titanium oxide nanopowder into a ceramic green body;

[0071] 3) Sintering the ceramic green body in a vacuum atmosphere or an inert atmosphere to obtain the titanium oxide target.

[0072] In the present invention, the modified titanium oxide nanopowder is prepared as follows:

[0073] i) providing the first mixture containing titanium oxide nanopowder, reducing organic matter and solvent;

[0074] ii) ball milling the first mixture to obtain a second mixture;

[0075] iii) drying the second mixture to obtain a third mixture;

[0076] iv) calcining the third mixture to obtain a fourth mixture;

[0077] v) cooling the fourth mixture to obtain the modified titanium oxide nanopowder.

[0078] In another preferred example, the particle size of the titanium oxide nanopowder i...

Embodiment 1

[0143] Embodiment 1 Preparation of modified titanium oxide powder 1

[0144] 1. Mix titanium dioxide powder in rutile crystal form (with a particle size of about 350 nm), citric acid and water at a molar ratio of 1:0.05:0.3 to obtain mixture 1.

[0145] 2. The above mixture 1 is ball milled for 10-15 hours to form slurry 1;

[0146] 3. Take out the above slurry 1 and place it in an oven at 70-80°C to dry for 10-15 hours, then calcinate at 350-400°C for 3-5 hours at a low temperature, and grind to form powder after cooling to obtain modified titanium oxide powder 1. As a starting material for ceramic sintering.

[0147] result

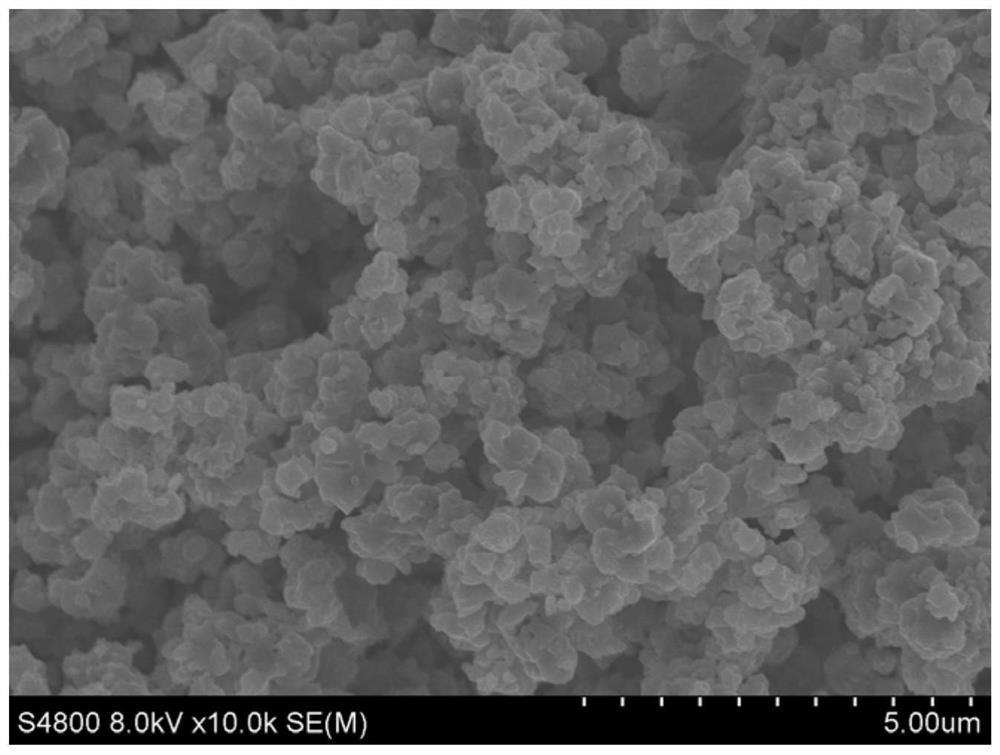

[0148] The modified titanium oxide powder 1 obtained in Example 1 was detected by SEM or the like.

[0149] figure 1 It is the SEM detection result of the modified titanium oxide powder 1 obtained in Example 1.

[0150] from figure 1 It can be seen that the particle size of the modified titanium oxide powder 1 is about 300-500 nanometers.

Embodiment 2

[0151] Embodiment 2 Preparation of modified titanium oxide powder 2

[0152] Same as Example 1, the difference is that ethylene glycol is used instead of citric acid, and the mixing molar ratio of the rutile crystal form titanium dioxide powder (particle size is about 350nm), ethylene glycol and water described in step 1 is 1:0.1:0.4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com