Fenton-like catalyst and preparation method of same

A catalyst and type of technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve problems such as insufficient mineralization of organic matter, easy dissolution of metal ions, and narrow use range, and achieve good results. Application prospect, easy recovery, and the effect of wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

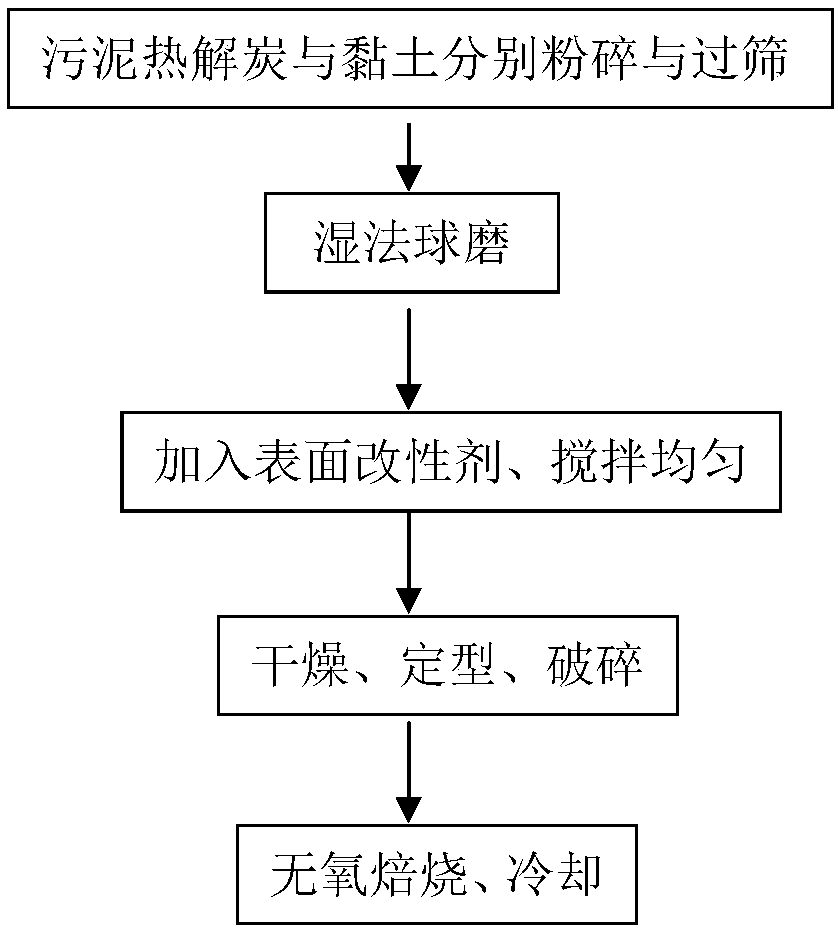

[0043] according to figure 1 The method for preparing a Fenton-like catalyst includes: 1) pulverizing and sieving the dried sludge pyrolytic carbon and clay respectively to obtain sludge pyrolytic carbon powder and clay powder;

[0044] 2) adding the sludge pyrolytic carbon powder and clay powder obtained in 1) into a ball mill, adding water to carry out wet ball milling, and filtering to obtain a ball mill slurry;

[0045] 3) Stir after adding a surface modifier to the ball mill slurry in 2), to obtain a uniformly dispersed modified slurry;

[0046] 4) Drying and shaping the modified slurry in 3) and crushing to obtain a roasted blank;

[0047] 5) The roasted billet in 4) is anaerobically roasted under a protective atmosphere, and a Fenton-like catalyst is obtained after cooling.

[0048] Specifically, the sludge pyrolytic carbon and kaolin that were carbonized at 700°C for 30 minutes were dried and pulverized, passed through a 100-mesh sieve, and then 10% of the total weig...

Embodiment 2

[0054] The process for preparing Fenton-like catalysts using sludge pyrolytic carbon is the same as in Example 1. The sludge pyrolytic carbon and kaolin that were carbonized at 600°C for 40 minutes were dried and pulverized, passed through a 100-mesh sieve, and then weighed to account for 20% of the total weight. % kaolin is mixed with sludge charcoal powder accounting for 80% of the total weight, the amount of water added is controlled to a solid-liquid mass ratio of 1:3, and wet ball milling is carried out to obtain ball mill slurry. The rotating speed of the ball mill is 400r / min, and the ball milling time is 4h. After the ball milling, pass through a 300-mesh sieve to obtain ultrafine uniform slurry. Next, add 1% surface modifier stearic acid into the ball mill slurry, and then carry out mechanical stirring to obtain modified slurry. The speed of mechanical stirring is 400r / min, and the stirring time is 20min. Then the modified slurry is vacuum-dried at 70° C. for 8 hours...

Embodiment 3

[0058] The process for preparing Fenton-like catalysts using sludge pyrolytic carbon is the same as in Example 1. The sludge pyrolytic carbon and kaolin obtained by carbonizing at 500°C for 50 minutes were dried and pulverized, passed through a 100-mesh sieve, and then weighed to account for the total weight. Mix 30% of kaolin with 70% of total weight of sludge pyrolytic carbon powder, add water to control the solid-to-liquid mass ratio of 1:2, perform wet ball milling to obtain ball mill slurry, and pass through a 350-mesh sieve after ball milling to obtain ultrafine Uniform slurry. The rotational speed of the ball mill was 300r / min, and the ball milling time was 6h. Then add 1.5% surface modifier quaternary ammonium compound into the ball mill slurry, and then carry out magnetic stirring to obtain modified slurry. The speed of magnetic stirring is 500r / min, and the stirring time is 10min. Then the modified slurry is vacuum-dried at 80° C. for 6 hours. After setting, it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com