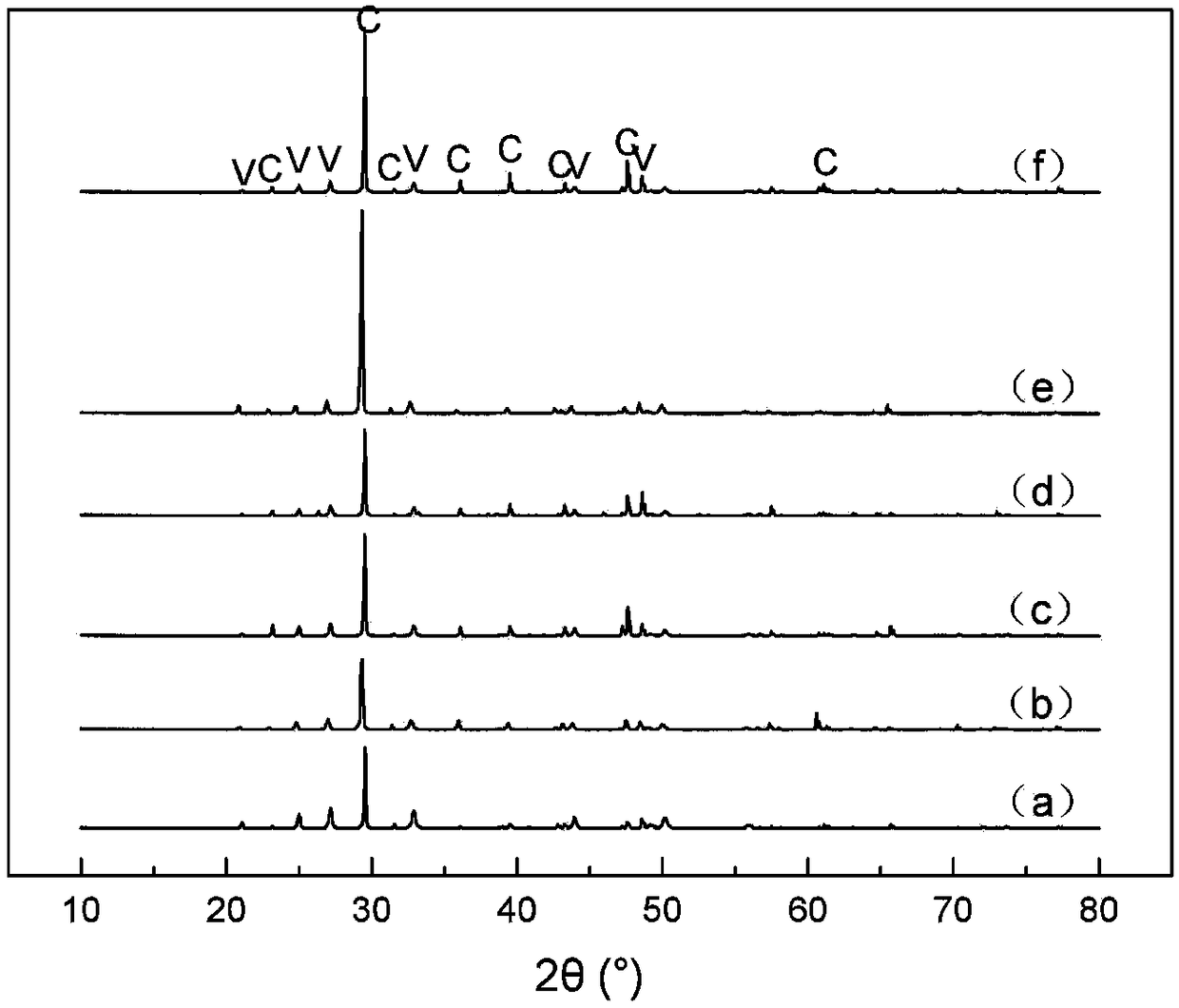

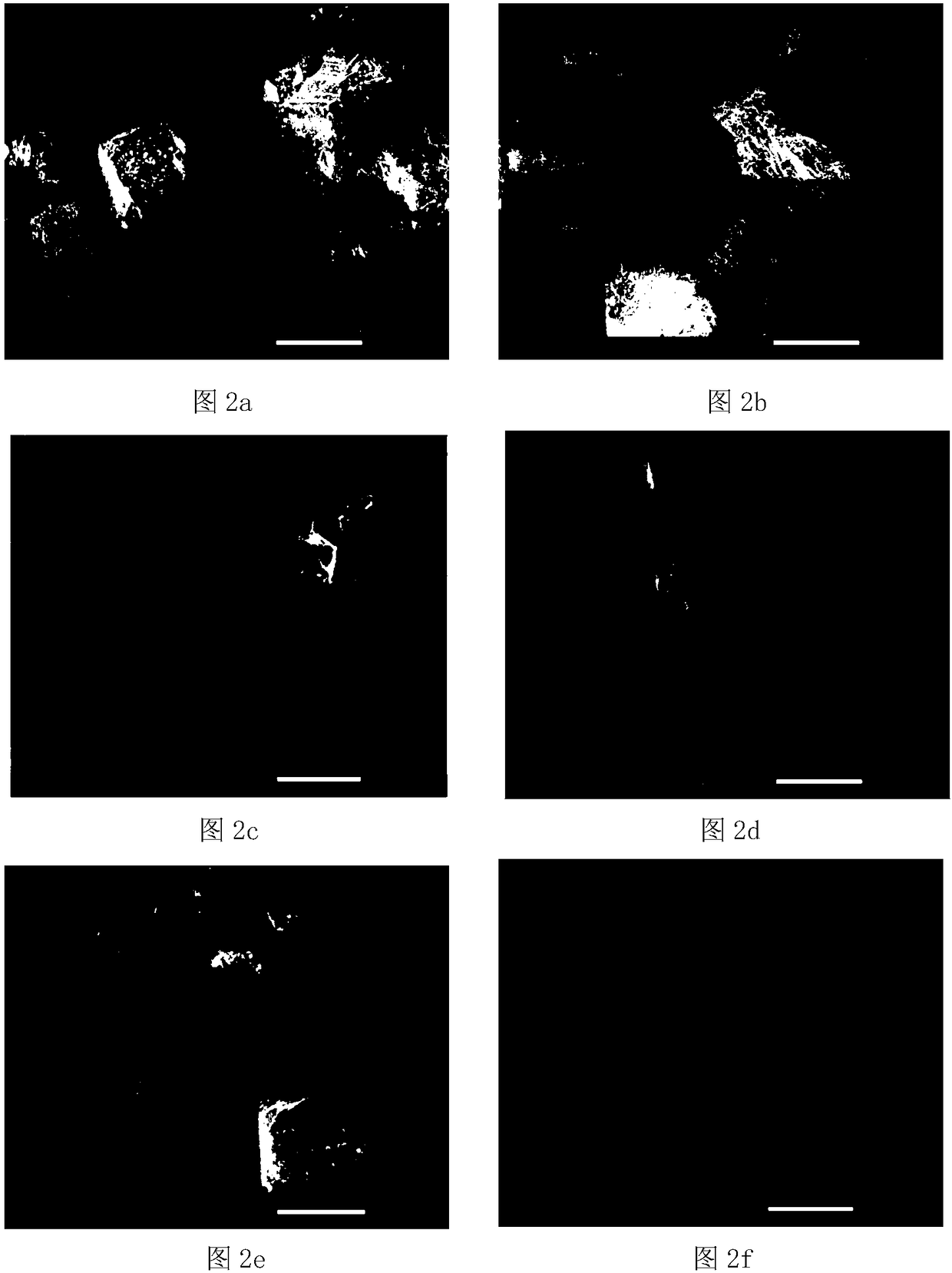

Method for preparing calcium carbonate by simultaneous mineralization of two microorganisms

A technology of microorganisms and calcium carbonate, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of pollution and slow mineralization rate, and achieve the effects of environmental friendliness, high preparation efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of method that utilizes two kinds of microorganisms to mineralize jointly to prepare calcium carbonate, the steps are as follows:

[0049] (1) Preparation of culture medium for Bacillus sarcina pasteurii: Weigh 15.75g of Tris and dissolve it in 1L of distilled water, adjust the pH with 50% hydrochloric acid to make a Tris-Hcl buffer solution with a pH of 9.0, then weigh the yeast extract 20g of ammonium sulfate, 10g of ammonium sulfate, dissolved in 1LTris-Hcl buffer; preparation of culture medium for Bacillus pumilus: Weigh 5g of peptone, 1.5g of beef extract, 1.5g of yeast extract, 5g of NaCl, and dissolve in 1L of distilled water Adjust the pH to 8.0. The prepared liquid medium was divided into Erlenmeyer flasks, sterilized at 121°C for 20 minutes, and then taken out for use.

[0050] (2) Take by weighing 166.5g of anhydrous calcium chloride, 60.1g of urea is dissolved in 1L distilled water, mix well, the concentration of calcium chloride in this mixed soluti...

Embodiment 2

[0055] A kind of method that utilizes two kinds of microorganisms to mineralize jointly to prepare calcium carbonate, the steps are as follows:

[0056] (1) Preparation of culture medium for Bacillus sarcina pasteurii: Weigh 15.75g of Tris and dissolve it in 1L of distilled water, adjust the pH with 50% hydrochloric acid to make a Tris-Hcl buffer solution with a pH of 9.0, then weigh the yeast extract 20g of ammonium sulfate, 10g of ammonium sulfate, dissolved in 1LTris-Hcl buffer; preparation of culture medium for Bacillus pumilus: Weigh 5g of peptone, 1.5g of beef extract, 1.5g of yeast extract, 5g of NaCl, and dissolve in 1L of distilled water Adjust the pH to 8.0. The prepared liquid medium was divided into Erlenmeyer flasks, sterilized at 121°C for 20 minutes, and then taken out for use.

[0057] (2) Take by weighing 166.5g of anhydrous calcium chloride, 60.1g of urea is dissolved in 1L distilled water, mix well, the concentration of calcium chloride in this mixed soluti...

Embodiment 3

[0062] A kind of method that utilizes two kinds of microorganisms to mineralize jointly to prepare calcium carbonate, the steps are as follows:

[0063] (1) Preparation of culture medium for Bacillus sarcina pasteurii: Weigh 15.75g of Tris and dissolve it in 1L of distilled water, adjust the pH with 50% hydrochloric acid to make a Tris-Hcl buffer solution with a pH of 9.0, then weigh the yeast extract 20g of ammonium sulfate, 10g of ammonium sulfate, dissolved in 1L Tris-Hcl buffer; preparation of culture medium for Bacillus pumilus: Weigh 5g of peptone, 1.5g of beef extract, 1.5g of yeast extract, 5g of NaCl, and dissolve in 1L of distilled water Adjust the pH to 8.0. The prepared liquid medium was divided into Erlenmeyer flasks, sterilized at 121°C for 20 minutes, and then taken out for use.

[0064] (2) Take by weighing 166.5g of anhydrous calcium chloride, 60.1g of urea is dissolved in 1L distilled water, mix well, the concentration of calcium chloride in this mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com