Preparation method of novel papermaking sizing agent

A sizing agent, a new type of technology, used in papermaking, textiles and papermaking, paper, etc., can solve the problems of water resistance, unsatisfactory AKD, environmental and safety hazards, and achieve good sizing effect, heat resistance and other problems. Good water effect and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

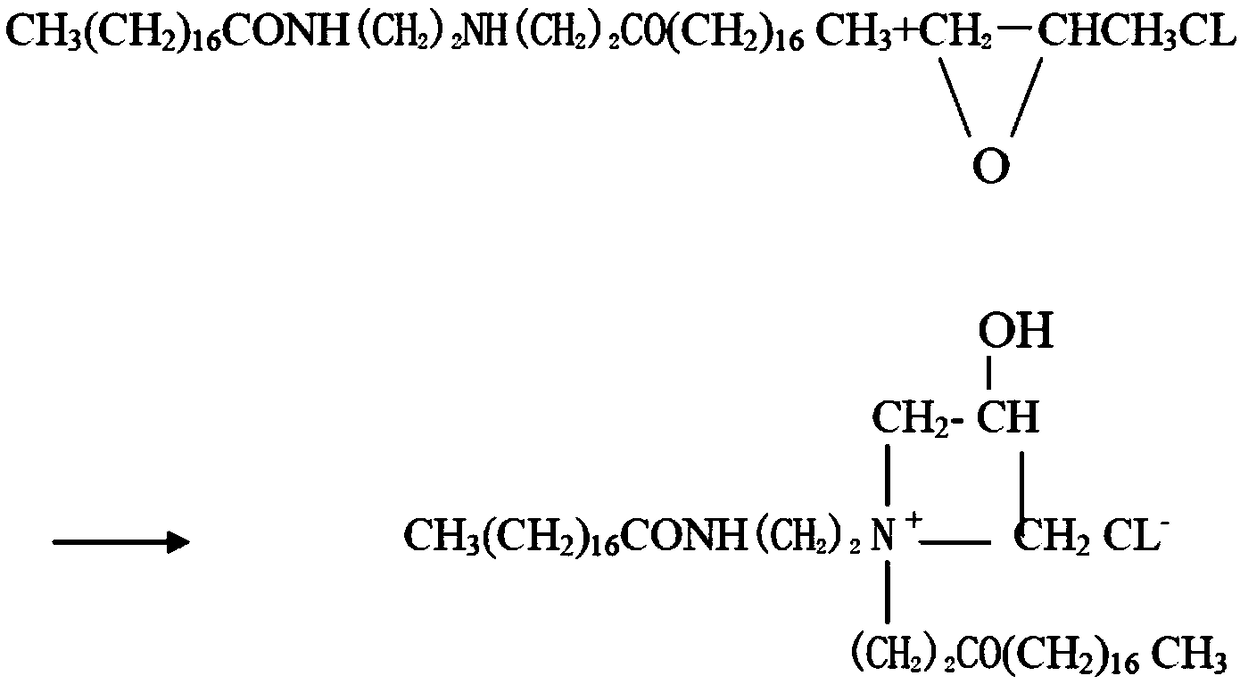

Method used

Image

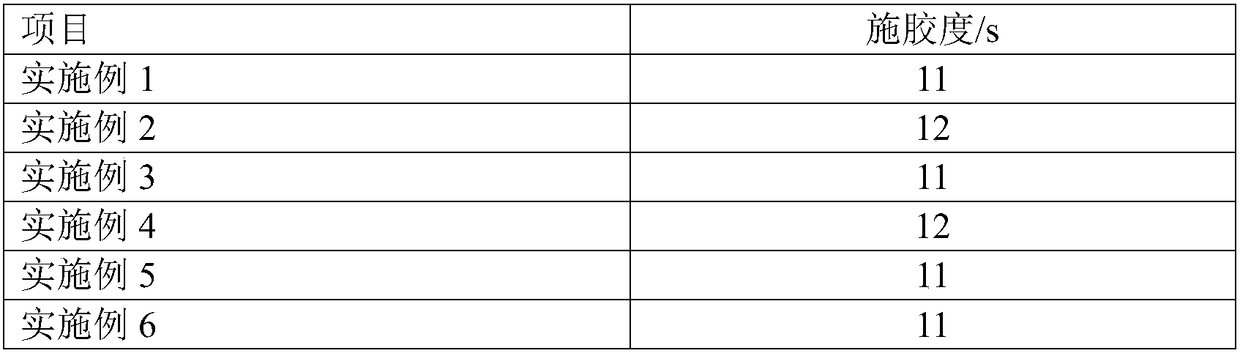

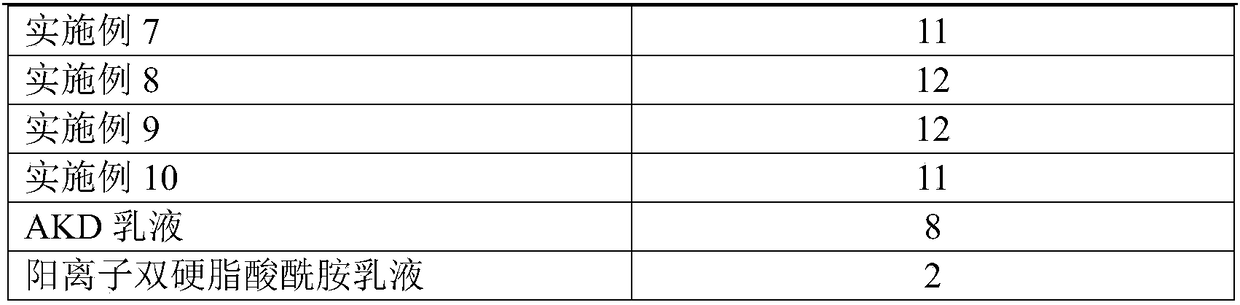

Examples

Embodiment 1

[0036] A. Take 60 g of stearic acid, 2 g of diethanolamine, and 6 g of diethylenetriamine, react at 140° C. for 6 hours, cool down to 110° C., and obtain a reaction feed liquid, which is set aside;

[0037] B. Take 100g of water and 3g of cationic cornstarch. After mixing, gelatinize at 90°C for 1 hour, cool down to 50°C to obtain gelatinized starch liquid, add 5g of the reaction material liquid obtained in step A to the gelatinized starch liquid, and add compound surface active Add 0.2g of epichlorohydrin dropwise, add 3g of epichlorohydrin dropwise, heat up to 70°C, keep warm for 5 hours, add 5g of water, cool down to room temperature, and obtain a white emulsion, which is the papermaking sizing agent.

[0038] Wherein the composite surfactant is alkylphenol polyoxyethylene ether and cetyltrimethylammonium bromide with a mass ratio of 1:1.

Embodiment 2

[0040] A. Take 70g of stearic acid, 3g of diethanolamine, and 7g of diethylenetriamine, react at 220°C for 4h, cool down to 120°C, and obtain the reaction feed liquid, which is set aside;

[0041] B. Take 100g of water and 10g of polyamide epichlorohydrin resin, mix and heat up to 50°C to obtain a mixed solution, add 14g of the reaction material solution obtained in step A to the mixed solution, add 1g of composite surfactant, and dropwise add epoxy chlorine Add 5g of propane, raise the temperature to 70°C, keep it warm for 2 hours, add 5g of water, cool down to room temperature, and obtain a white emulsion, which is the paper-making sizing agent.

[0042] Wherein the composite surfactant is OP-10 and cetyltrimethylammonium chloride with a mass ratio of 3:2.

Embodiment 3

[0044] A. Take 80g of stearic acid, 2.5g of diethanolamine, and 8g of diethylenetriamine, react at 180°C for 5h, cool down to 115°C, and obtain the reaction feed liquid, which is set aside;

[0045] B. Take 100g of water and 6g of cationic tapioca starch. After mixing, gelatinize at 90°C for 1 hour, cool down to 45°C to obtain gelatinized starch liquid, add 7g of the reaction material liquid obtained in step A to the gelatinized starch liquid, and add compound surface active Add 0.5g of epichlorohydrin dropwise to 7g of epichlorohydrin, heat up to 70°C, keep warm for 2.5 hours, add 5g of water, cool down to room temperature, and obtain a white emulsion, which is the paper-making sizing agent.

[0046] Wherein the composite surfactant is T-40 and cetyltrimethylammonium chloride with a mass ratio of 2:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com