HEMT (high electron mobility transistor) device with back field plate structure and preparation method of HEMT device

A back field plate and device technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as thermal breakdown, gate drain side electrical breakdown, silicon substrate breakdown, etc. The effect of breakdown voltage, mitigating electric field peaks, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

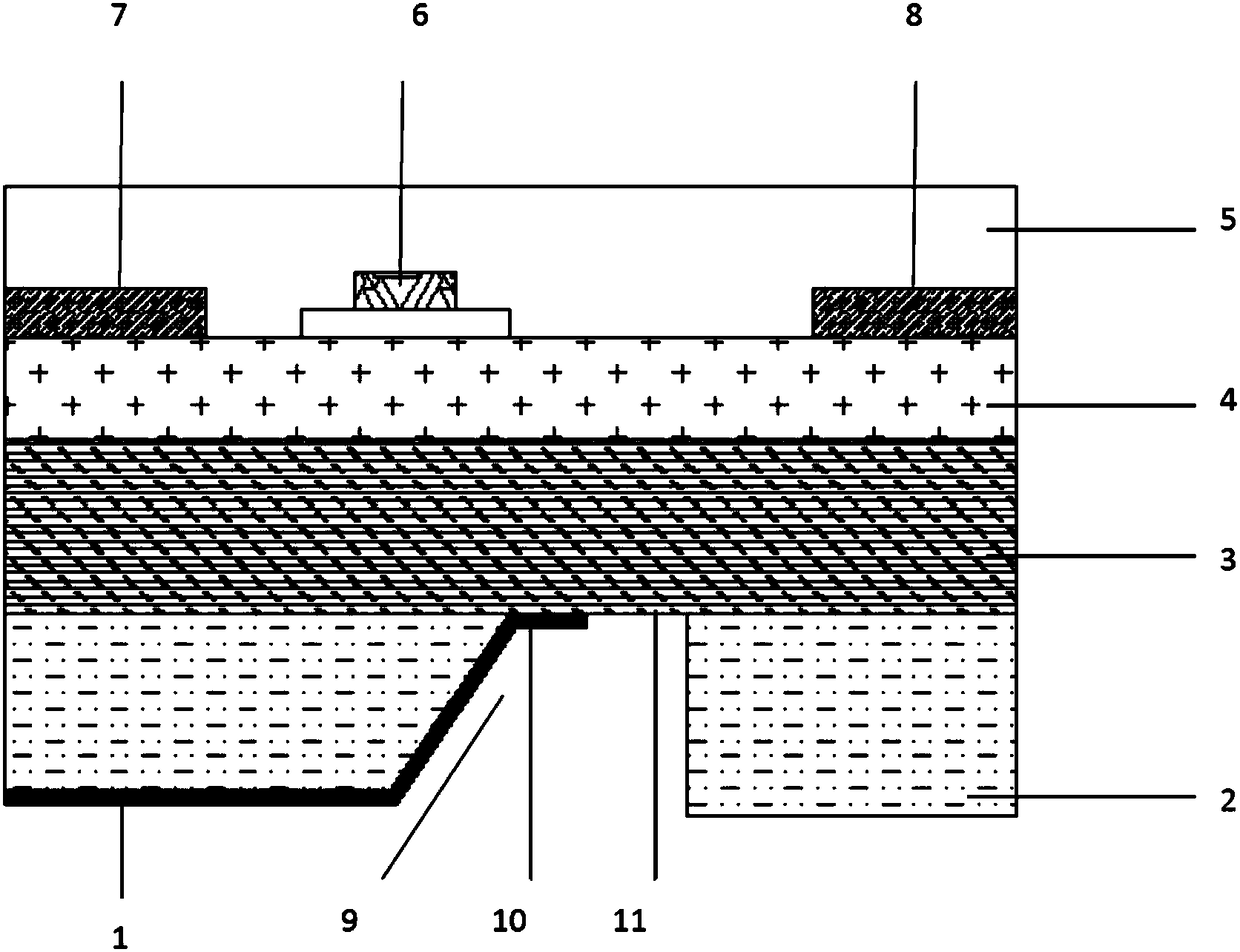

[0027] Such as figure 1 As shown, the HEMT device with the back field plate structure of the present invention includes a silicon substrate 2, a GaN epitaxial layer 3, an AlGaN barrier layer 4, a Si 3 N 4 A passivation protection layer 5; a gate electrode 6, a source electrode 7 and a drain electrode 8 are arranged on the AlGaN barrier layer 4; the silicon substrate is provided with a groove 9 whose cross section is a right-angled trapezoid; Next, the top of the groove is the lower surface of the GaN epitaxial layer; the back field plate structure 1 is set on part of the lower surface of the silicon substrate, the slope of the groove, and part of the top of the groove. The contact line width 10 between the back field plate structure and the GaN epitaxial layer is 5-10 μm. The lateral width of the portion 11 of the groove top not covered by the back field plate structure is 5-10 μm. The back field plate structure is a metal sheet with a thickness of 50nm-2μm.

[0028] A met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com