Method and device for separating high-purity CO2 from CO2-containing raw gas

A raw gas, high-purity technology, used in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reducing the use efficiency of adsorbents, large compression energy consumption, large pressure drop, etc., to overcome the use of adsorbents. Low efficiency, overcoming the effect of high energy consumption of vacuum pump and huge economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

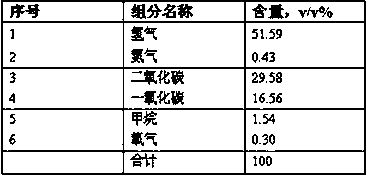

[0060] Hydrogen tail gas from petrochemical refinery methane steam reforming (containing CO 2 Raw material gas) to separate and extract high-purity CO 2 .

[0061] Tail gas (including CO 2 feed gas) is rich in CO 2 The industrial tail gas, its usual components are as follows:

[0062] Table 1 Components of exhaust gas from methane steam reforming hydrogen production system in petrochemical refinery

[0063]

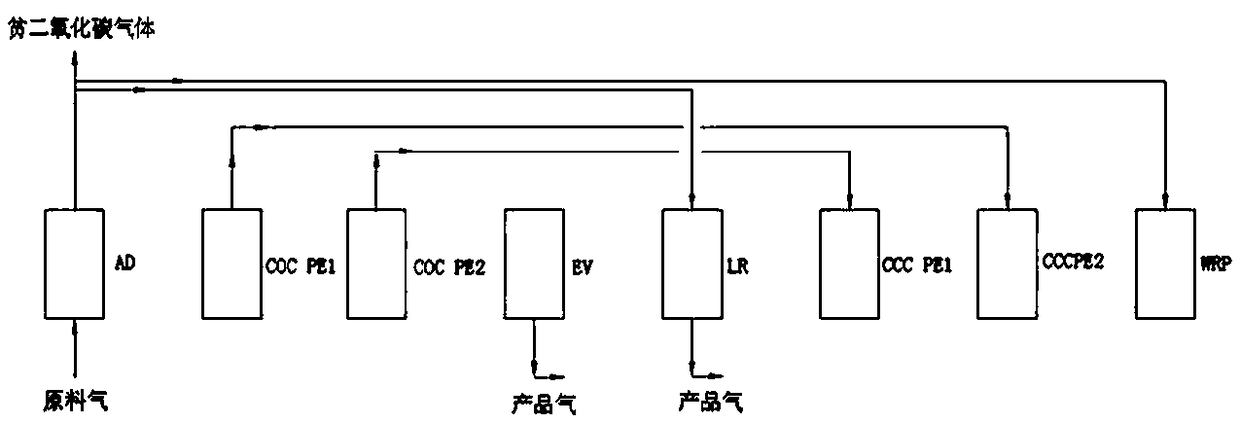

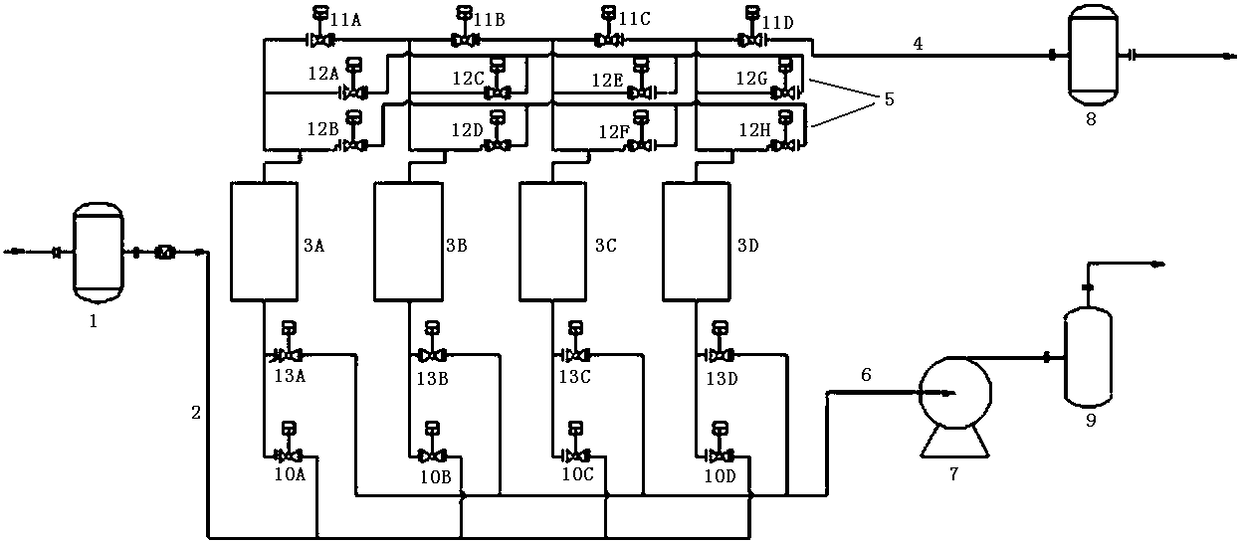

[0064] According to each parameter listed in embodiment 1-3 in table 3 use such as figure 1 Shown gas separation method of the present invention and as figure 2 The shown vacuum variable pressure gas separation device separates the above raw material gas, wherein the number of adsorption towers in the vacuum variable pressure gas separation device is not limited to figure 2 For the four shown, the specific number of adsorption towers is shown in Table 3. The adsorbent in the adsorption tower is silica gel, activated carbon and zeolite X (the filling ratio is 1...

Embodiment 4-6

[0066] Syngas from coal (including CO 2 Raw material gas) to separate and extract high-purity CO 2 .

[0067] Coal-to-synthesis gas (including CO 2 feed gas) is rich in CO 2 Industrial gas, its usual components are as follows:

[0068] Table 2 Composition of coal-to-synthesis gas

[0069]

[0070] According to each parameter listed in embodiment 4-6 in table 3 use such as figure 1 Shown gas separation method of the present invention and as figure 2 The vacuum swing gas separation unit shown separates the above feed gas, wherein a feed gas pressurization step is used instead of figure 1 CO depleted as described in 2 Gas pressurization step, the remaining steps are the same as figure 1 same. The number of adsorption towers in the vacuum swing gas separation device is not limited to figure 2 For the four shown, the specific number of adsorption towers is shown in Table 3. The adsorbent in the adsorption tower is silica gel, activated carbon and zeolite X (the fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com