A kind of preparation method of boron-containing nu-87 molecular sieve

A NU-87, molecular sieve technology, applied in molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problem of high preparation cost, and achieve the effect of reducing preparation cost, simple process and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

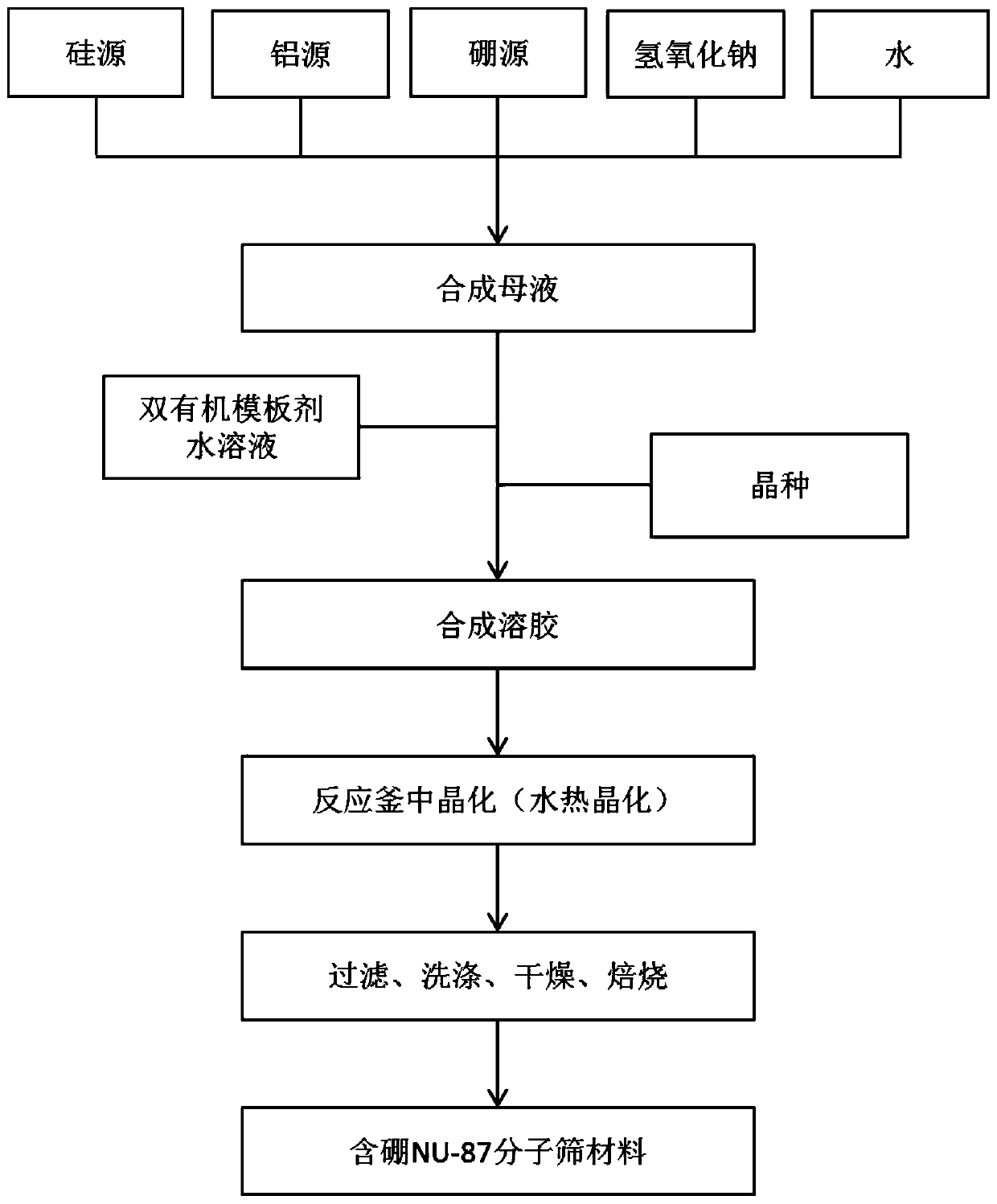

[0030] The present invention provides a kind of preparation method of boron-containing NU-87 molecular sieve, wherein, the method comprises:

[0031] (1) provide a kind of mother liquor, described mother liquor contains silicon source, aluminum source, boron source, sodium hydroxide and water,

[0032] And provide a kind of templating agent solution, described templating agent solution contains first templating agent R1, second templating agent R2 and water; Described first templating agent R1 is brominated decacene quaternary ammonium, and described second templating agent R2 At least one of tri-n-propylamine, 1,3-propanediamine, 1,4-butanediamine, 1,6-hexanediamine and 1,8-octanediamine, preferably 1,3-propanediamine Amines and 1,4-butanediamine;

[0033] (2) under stirring, the template solution is added to the mother liquor, and a seed crystal is added to obtain a synthetic sol;

[0034] (3) hydrothermal crystallization of the synthetic sol;

[0035] (4) The mixture obt...

Embodiment 1

[0072] This example is used to illustrate the preparation of the boron-containing NU-87 molecular sieve of the present invention.

[0073] The process for preparing boron-containing NU-87 molecular sieves is as follows figure 1 shown.

[0074] At room temperature and under stirring, sodium hydroxide, sodium metaaluminate, boric acid, silica sol and deionized water are mixed and dissolved to form a molecular sieve synthesis mother liquor.

[0075] Mixing and dissolving bromodecadecane quaternary amine (R1) and 1,3-propanediamine (R2) in deionized water at room temperature to prepare an aqueous solution of an organic template.

[0076] At room temperature and under stirring, an aqueous solution of an organic template is added to the mother liquor for synthesizing molecular sieves, and SiO 2 SiO 2 -Al 2 o 3 -B 2 o 3 -Na 2 O-R1-R2-H 2 O stable sol, the molar ratio of each component in the sol system is: 55SiO 2 :0.5Al 2 o 3 :0.5B 2 o 3 :3R1:3R2:11Na 2 O:2600H 2 O. ...

Embodiment 2

[0080] This example is used to illustrate the preparation of the boron-containing NU-87 molecular sieve of the present invention.

[0081] The boron-containing NU-87 molecular sieve was prepared according to the synthesis process of Example 1, except that the molar ratio of R1:R2=5:2.5. After the crystallization reaction product was filtered, washed and dried at 80°C for 12 hours, it was placed in a muffle furnace and raised to 550°C at a heating rate of 2°C / min and kept for 6 hours to remove the template agent to obtain boron-containing NU- 87 molecular sieves.

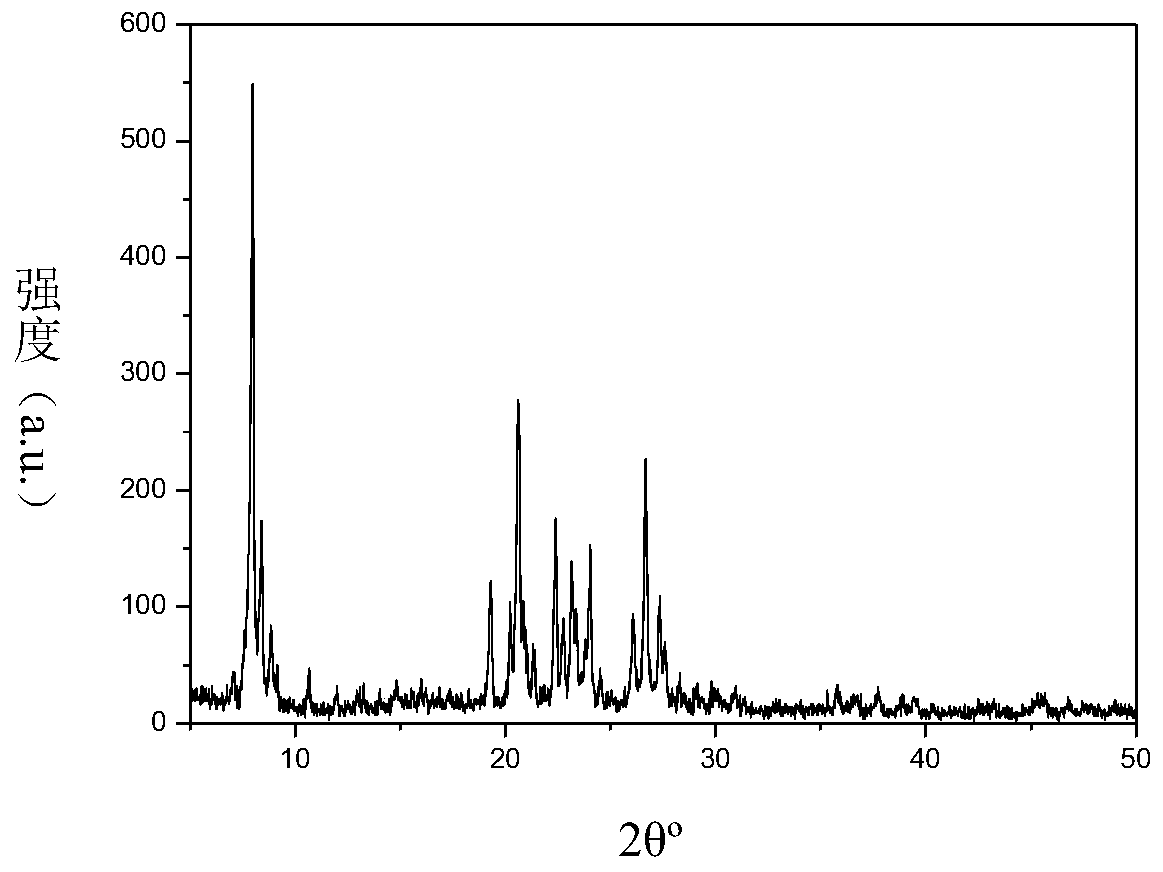

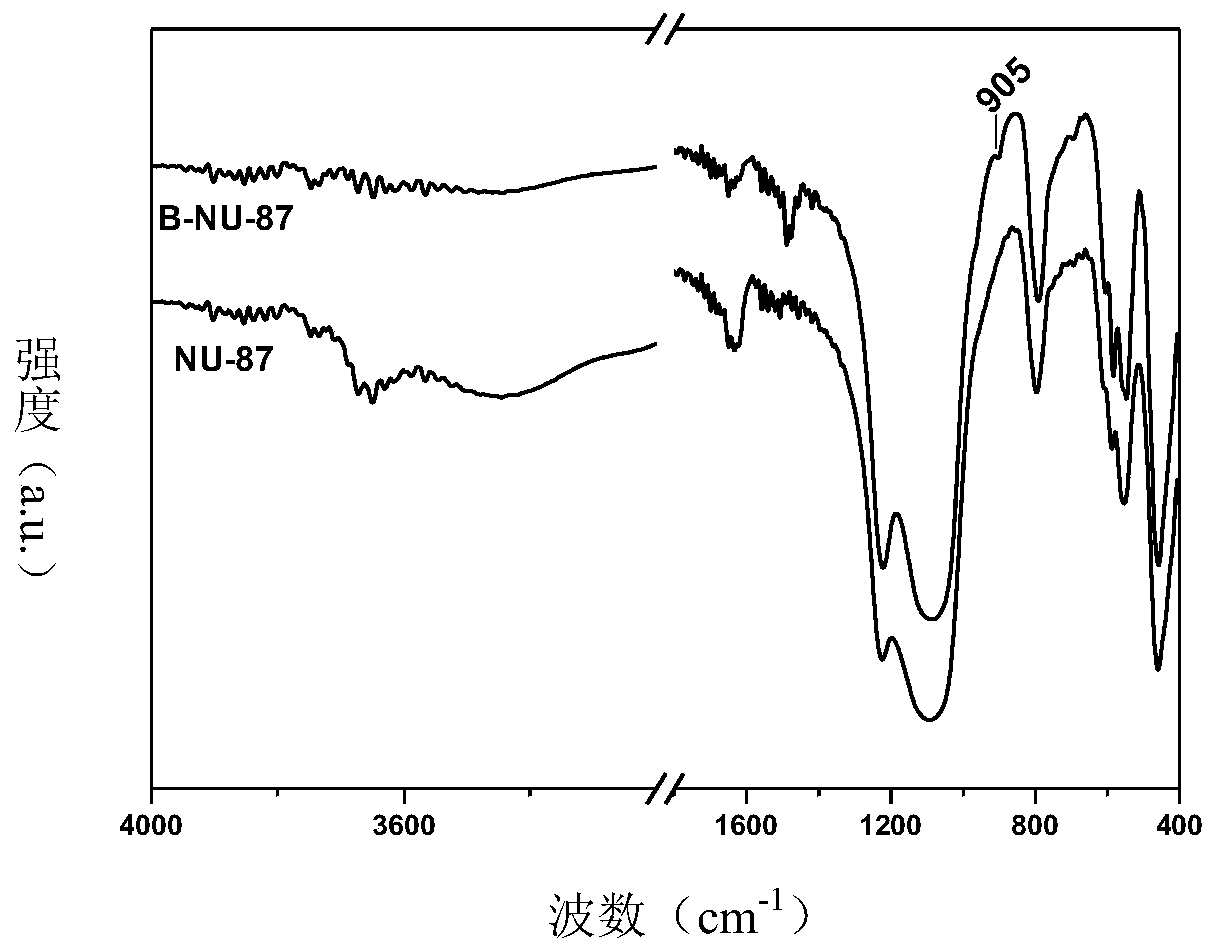

[0082] The sample was characterized as boron-containing NU-87 molecular sieve by XRD and IR.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com