A double-chamber double-bottom side-blowing furnace for zinc leaching slag treatment and its treatment method

A technology of zinc leaching slag and side-blowing furnace, which is applied to the double-chamber double-bottom side-blowing furnace for zinc leaching slag treatment and its treatment field, can solve the problems of low recovery rate, large equipment area, complicated operation, etc. Valence metal content, valuable metal content reduction, the effect of environmental friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

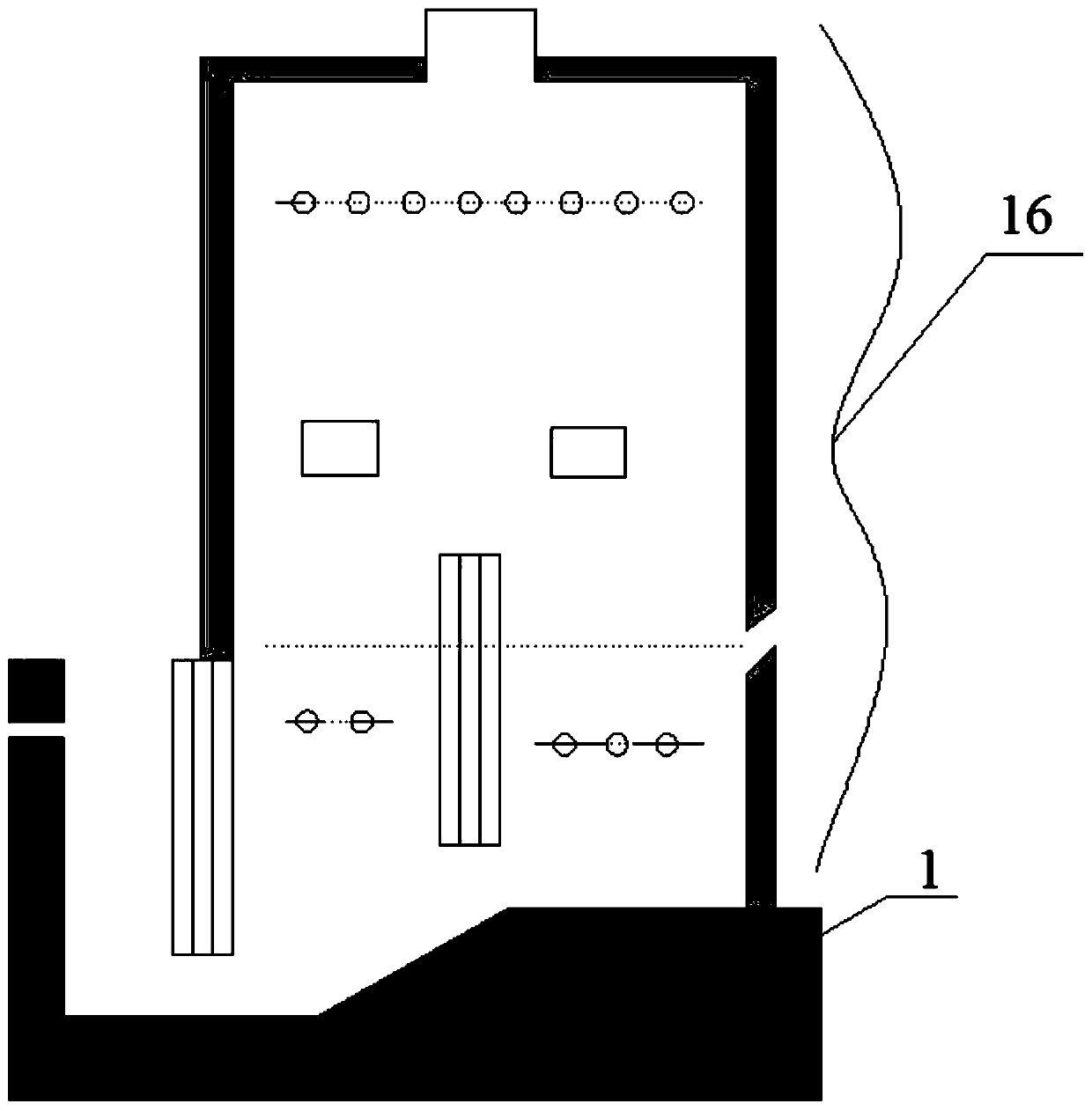

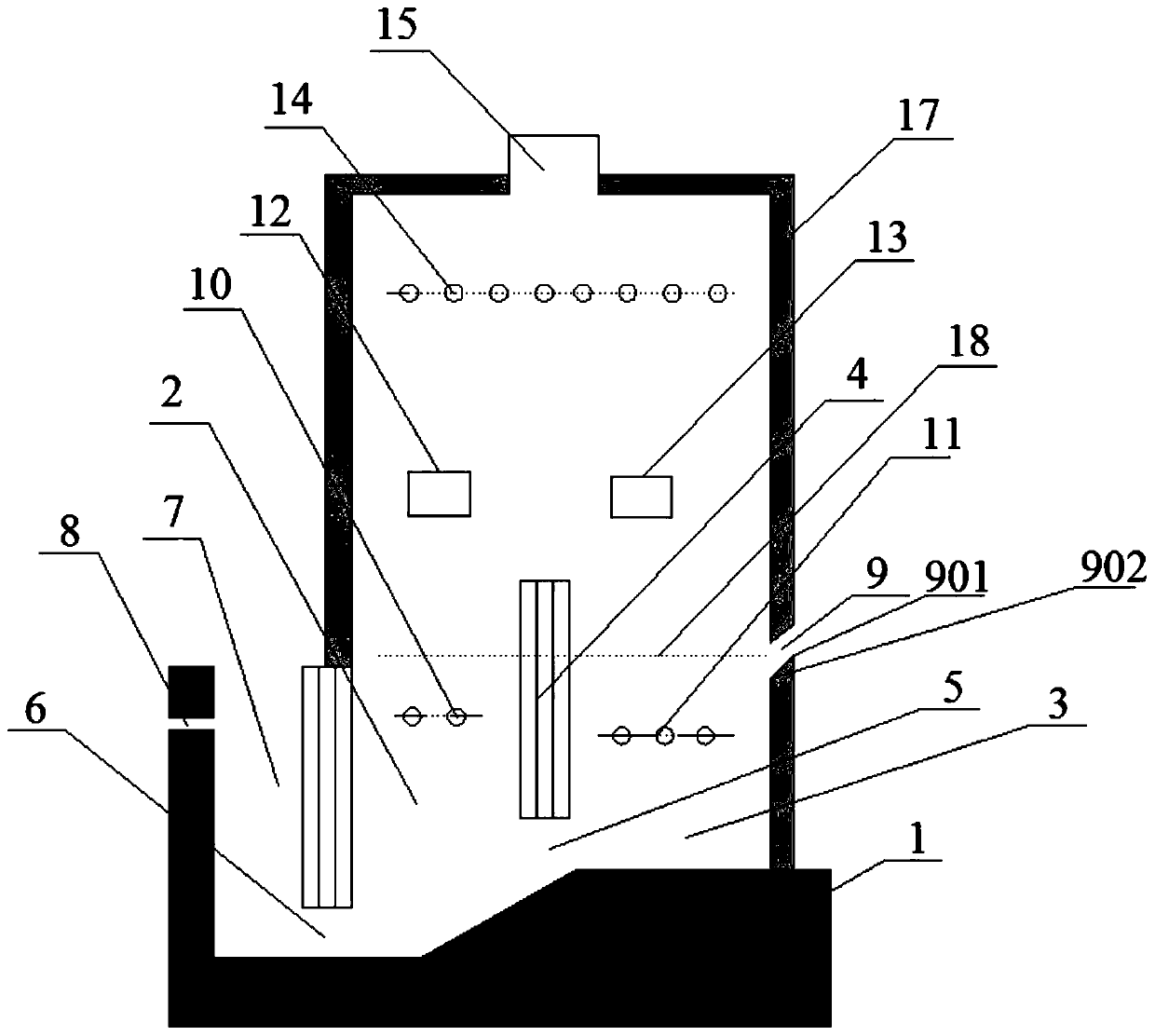

[0041] A double-chamber double-bottom side-blowing furnace for zinc leaching slag treatment, the side-blowing furnace includes a high and low hearth 1, and the upper part of the high and low hearth 1 is divided into a smoke chamber 2 and a depletion chamber 3 by an intermediate partition wall 4 The bottom of the smoke chamber 2 and the depletion chamber 3 are connected through a channel 5; the chamber with a low cylinder bottom in the high and low hearth is the smoke chamber 2, and the chamber with a high cylinder bottom is the depletion chamber. The hearth bottom of the fuming chamber 2 is 100-500mm lower than the bottom of the hearth of the depletion chamber 3, and the bottom of the middle partition wall 4 and the bottom of the hearth bottom of the depletion chamber 3 The distance is 200-300mm (that is, the distance forms a passage connecting the bottom end of the fume chamber and the depletion chamber); the fume chamber 2 communicates with the matte siphon well 7 through the...

Embodiment 2

[0048] Utilize the zinc leaching slag described in embodiment 1 to process the method for processing zinc leaching slag in double-chamber double-bottom side-blown furnaces, comprising the following steps:

[0049] (1) Collect the zinc leaching slag to be treated and place it for subsequent use; the main components in the collected zinc leaching slag are: Zn: 20-21%, SiO 2 : 8-10%, Fe: 21-22%, CaO: 3-4%, Pb: 2-3%, Cu: 0.8-1.0%, water 10-13%, the rest is impurities; and prepare reducing agent, Slag forming agent and matte forming agent shall be kept for later use;

[0050] (2) Open the fuming chamber gas lance and the depletion chamber gas lance in the double-chamber double-bottom side-blowing furnace, feed natural gas and oxygen-enriched air, the pressures of the natural gas and oxygen-enriched air are both 0.12MPa, and The volume ratio of natural gas and oxygen in oxygen-enriched air is 1:2;

[0051] After the natural gas and oxygen-enriched air are adjusted, the zinc leachi...

Embodiment 3

[0061] Utilize the zinc leaching slag described in embodiment 1 to process the method two of double-chamber double-bottom side blowing furnace processing zinc leaching slag, comprise the following steps:

[0062] (1) Collect the zinc leaching slag to be treated and place it for subsequent use; the main components in the collected zinc leaching slag are: Zn: 21~22%, SiO 2 : 10-12%, Fe: 22-23%, CaO: 4-5%, Pb: 3-4%, Cu: 1.0-1.2%, water 13-15%, the rest is impurities; and prepare reducing agent, Slag forming agent and matte forming agent shall be kept for later use;

[0063] (2) Open the fuming chamber gas lance and the depletion chamber gas lance in the double-chamber double-bottom side blowing furnace, feed natural gas and oxygen-enriched air, the pressures of the natural gas and oxygen-enriched air are both 0.13MPa, and The volume ratio of natural gas and oxygen in oxygen-enriched air is 1:2.2;

[0064]After adjusting the incoming natural gas and oxygen-enriched air, the zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com