Compound lactic acid bacterium fermented fruit, vegetable and cereal drink, manufacturing method thereof and application thereof

A compound lactic acid bacteria and a manufacturing method technology are applied in the field of compound lactic acid bacteria fermented fruits, vegetables, grains and beverages, and can solve the problems of low fermentation rate of wheat germ or fruits and vegetables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121]3) Preparation of starter: under sterile conditions, inoculate activated lactic acid bacteria strains (Lactobacillus bulgaricus, Lactobacillus casei, Lactobacillus helveticus, Lactobacillus plantarum) in MRS liquid medium (1% peptone, beef Cream 1%, yeast extract 0.5%, diammonium hydrogen citrate 0.2%, glucose 2%, Tween 80 0.1%, sodium acetate 0.5%, dipotassium hydrogen phosphate 0.2%, magnesium sulfate 0.058%, manganese sulfate 0.025%, pH In 6.2-6.6), after culturing at 28°C for 24 hours, take 1% seed liquid and transfer it to MRS medium again, perform low-temperature centrifugation after culturing, remove the supernatant, and then add sterilized normal saline for washing , centrifuged again, and after repeating the bacterium 3 times, add appropriate sterile saline, and determine the lactic acid bacteria seed liquid that is finally inserted into the fruit juice by adjusting the absorbance value of the final liquid. Taking physiological saline as a reference, the wavelen...

Embodiment 1

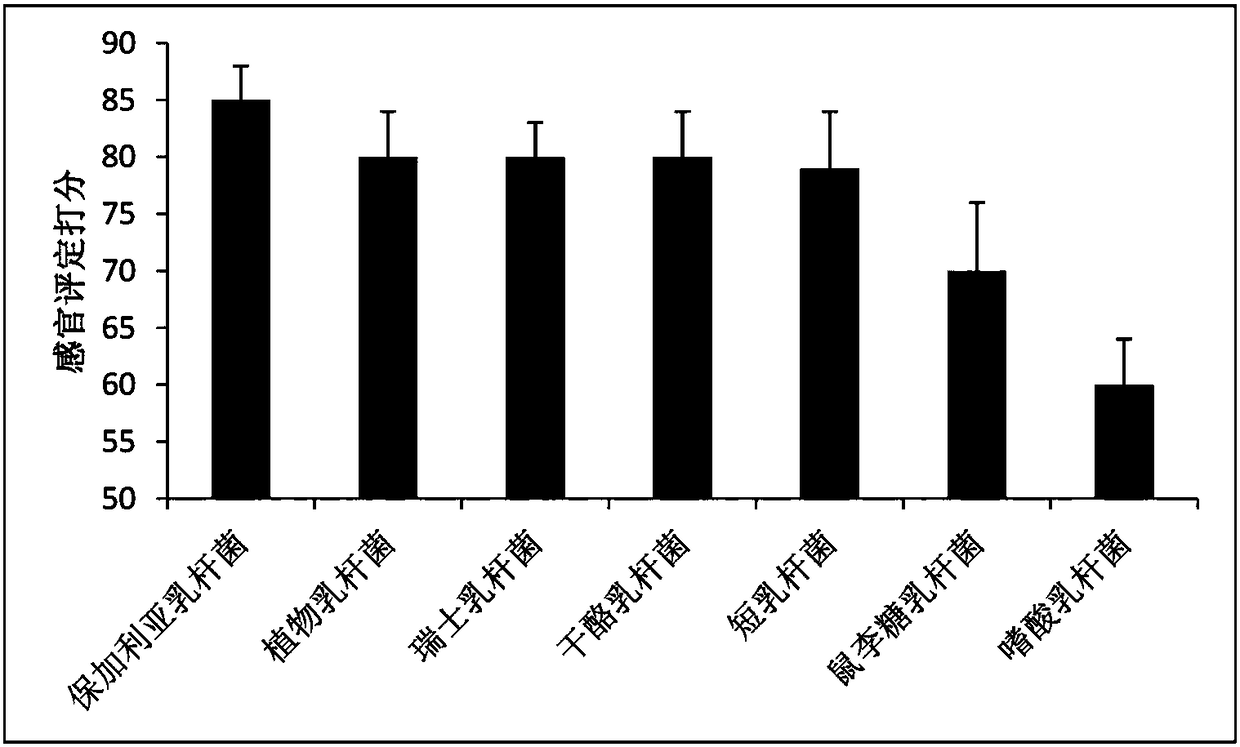

[0125] The determination of embodiment 1 fermentation strain

[0126] Get fresh apples (commercially available), peel and remove the core, cut the pulp into cubes of about 1 to 2 cm in size, add 0.1% vitamin C, 0.01% cysteine and 1.3 times the volume of apple water in the apple pieces, Squeeze the juice with a juicer, filter the squeezed juice through an 80-mesh sieve, and discard the filter residue to obtain apple juice.

[0127] Take fresh wheat germ (purchased at Guo Guoxiang Food Specialty Store in Jingdong Mall), put the crushed wheat germ into water with a solid-liquid ratio of 1:10 and extract it at 80°C for 2 hours, crush it with a mixer at high speed, and filter it with gauze. Discard the filter residue to obtain orange-yellow wheat germ juice. Unless otherwise stated, the apple juice and wheat germ juice thus obtained were used in the following examples.

[0128] Under sterile conditions, the activated strains (Lactobacillus bulgaricus, Lactobacillus casei, Lacto...

Embodiment 2

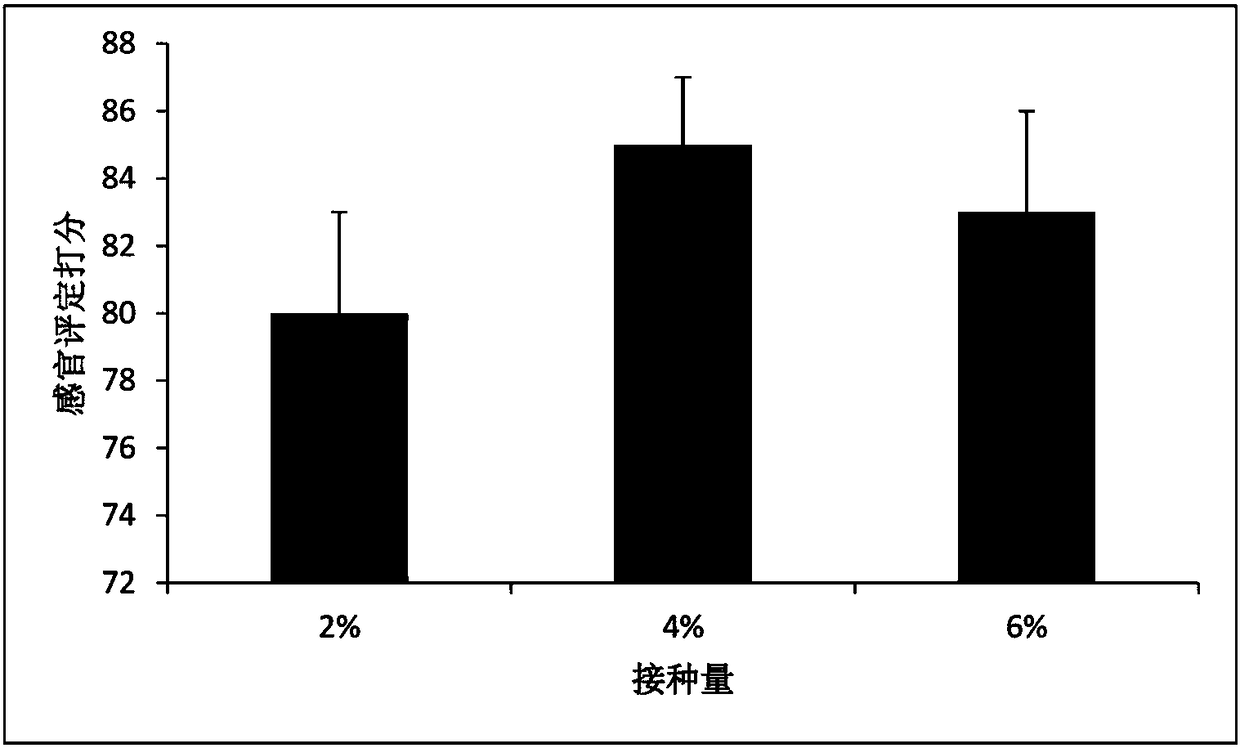

[0131] Different total inoculum size of embodiment 2

[0132] In the same manner as in Example 1, except that the lactic acid bacteria strains (the lactic acid bacteria strains used in this embodiment are Lactobacillus bulgaricus, Lactobacillus casei, Lactobacillus helveticus, plant milk mixed in a ratio of 1:1:1:1) Bacillus) after activation, inoculation and fermentation were carried out according to 2%, 4%, and 6% respectively, and the product status obtained by inoculation and fermentation with different proportions of bacteria was as follows: figure 2 As shown, the 2% inoculation amount has bright floating blocks, which are uneven, while the 4% and 6% inoculum amounts are relatively clear and transparent. Carry out sensory evaluation experiment to three products, its result is as follows image 3 Shown, the inoculum amount is 4% mouthfeel is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com