Weight-losing capsule based on biodegradable stent material

A technology of scaffold materials and degradable materials, which is applied in the field of weight-loss capsules based on degradable scaffold materials, can solve the problems of complex use, continuous burden on the stomach, and long residence time, and achieve low difficulty, reduce food intake, and good degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

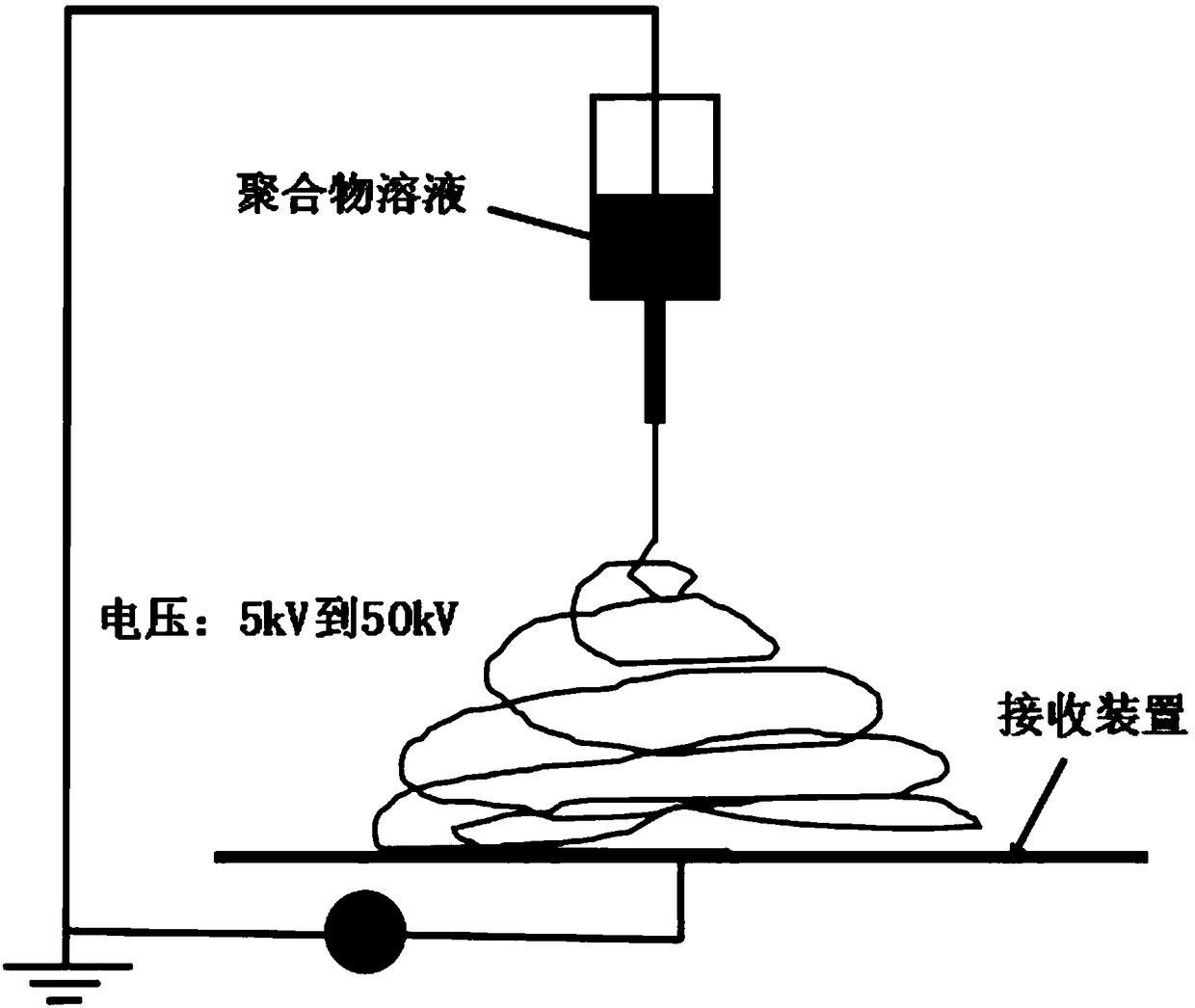

[0036] (1) Dissolve PCL in a mixed solvent of dichloromethane / N,N-dimethylformamide (ratio 40:60) at a concentration of 6 wt%, and electrospin to form a PCL film. The electrostatic high voltage is 10-15kV, the diameter of the receiving roller is 25cm, the length is 30cm, the receiving distance is 25cm, the flow rate is 3.0mL / h, and the rotational speed of the receiving roller is 100rpm.

[0037] (2) The PCL film obtained in the step (1) was soaked in liquid nitrogen to be brittle, ground 10 times, filtered, and the above steps were repeated 10 times to obtain PCL nanowires. Among them, the brittle fracture temperature of liquid nitrogen was -196°C, the soaking time was 10s, the grinding method was manual grinding in a mortar, and the frequency was 10-20 times, and the filtration was gauze filtration, and the filtering frequency was 2-5 times.

[0038] (3) Disperse the PCL nanowires prepared in step (2) in ethanol / water / gelatin mixed solution, wherein the concentration of gelat...

Embodiment 2

[0041] (1) PCL was dissolved in a mixed solvent of dichloromethane / N,N-dimethylformamide (ratio 50:50) at a concentration of 8 wt%, and electrospun into a PCL film. The electrostatic high voltage is 10-15kV, the diameter of the receiving roller is 25cm, the length is 30cm, the receiving distance is 25cm, the flow rate is 3.0mL / h, and the rotational speed of the receiving roller is 100rpm.

[0042] (2) The PCL film obtained in the step (1) was soaked in liquid nitrogen to be brittle, ground 10 times, filtered, and the above steps were repeated 10 times to obtain PCL nanowires. Among them, the brittle fracture temperature of liquid nitrogen was -196°C, the soaking time was 10s, the grinding method was manual grinding in a mortar, and the frequency was 10-20 times, and the filtration was gauze filtration, and the filtering frequency was 2-5 times.

[0043](3) Disperse the PCL nanowires prepared in step (2) in ethanol / water / gelatin mixed solution, wherein the concentration of gela...

Embodiment 3

[0046] (1) Dissolve PCL in a mixed solvent of dichloromethane / N,N-dimethylformamide (ratio 60:40) at a concentration of 9 wt%, and electrospin to form a PCL film. The electrostatic high voltage is 10-15kV, the diameter of the receiving roller is 25cm, the length is 30cm, the receiving distance is 25cm, the flow rate is 3.0mL / h, and the rotational speed of the receiving roller is 100rpm.

[0047] (2) The PCL film obtained in the step (1) was soaked in liquid nitrogen to be brittle, ground 10 times, filtered, and the above steps were repeated 10 times to obtain PCL nanowires. Among them, the brittle fracture temperature of liquid nitrogen was -196°C, the soaking time was 10s, the grinding method was manual grinding in a mortar, and the frequency was 10-20 times, and the filtration was gauze filtration, and the filtering frequency was 2-5 times.

[0048] (3) Disperse the PCL nanowires prepared in step (2) in ethanol / water / gelatin mixed solution, wherein the gelatin aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com