Preparation method of formaldehyde-free non-mildew non-combustible bamboo fiber board

A bamboo fiber and fiber technology, which is applied in the field of preparation of formaldehyde-free, mildew-free and non-combustible bamboo fiber board, can solve the problems of bamboo fiber board containing formaldehyde, easy to mildew, easy to burn, etc., and achieves a simple preparation method, good flame retardant performance, and easy raw materials. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

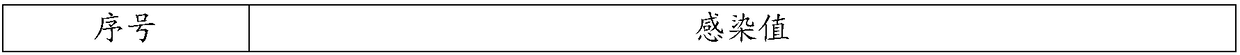

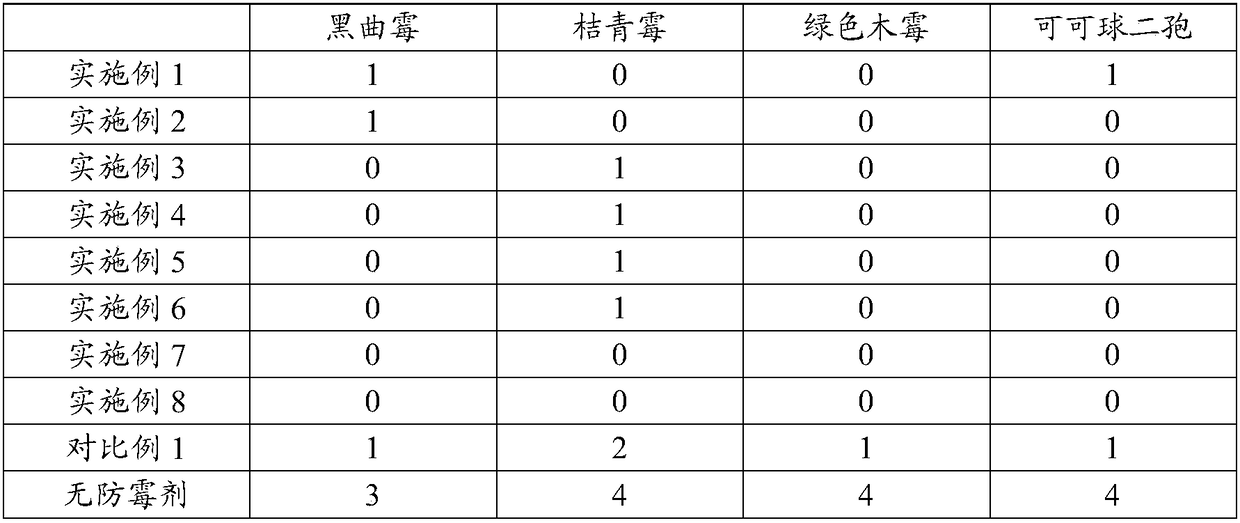

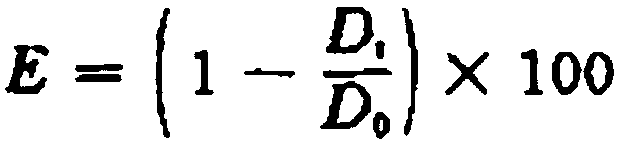

Examples

Embodiment 1

[0057] A preparation method of a Chinese herbal medicine antifungal agent is as follows: soak the Chinese herbal medicine in 70% ethanol solution, the mass ratio of the Chinese herbal medicine to ethanol is 1:5, heat up to 50°C, filter and remove the filter residue after heating for 120min, and obtain the Chinese herbal medicine concentration of 98.2mg / ml Chinese herbal antifungal agent;

[0058] The above-mentioned Chinese herbal medicine is composed of the following components in parts by weight: 20 parts of thyme, 50 parts of male clove, 15 parts of cinnamaldehyde and 10 parts of tangerine peel.

Embodiment 2

[0060] A preparation method of a Chinese herbal medicine antifungal agent is as follows: soak the Chinese herbal medicine in 40% ethanol solution, the mass ratio of the Chinese herbal medicine to ethanol is 1:20, heat up to 80° C., filter and remove the filter residue after heating for 30 minutes, and obtain the Chinese herbal medicine concentration of 52.7mg / ml Chinese herbal antifungal agent;

[0061] The above-mentioned Chinese herbal medicine is composed of the following components in parts by weight: 30 parts of thyme, 60 parts of male clove, 10 parts of cinnamaldehyde and 5 parts of tangerine peel.

Embodiment 3

[0063] A preparation method of a nano-silver-zinc composite antifungal agent is as follows: Weigh 75 parts of zinc acetate, 15 parts of anhydrous sodium carbonate, 5 parts of silver nitrate and 10 parts of sodium dodecylbenzenesulfonate, and grind them in a mortar Mix evenly, then wash with deionized water and absolute ethanol respectively, filter and dry, and then put it into a high-temperature roasting furnace for sintering at a temperature of 250-500°C to obtain a nano-silver-zinc composite antifungal agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com