Ceramic thermal barrier coating layer and method for quickly preparing coating layer through in-situ reaction

A thermal barrier coating and in-situ reaction technology, which is applied in the field of ceramic thermal barrier coating and in-situ reaction rapid preparation coating, can solve the problems of thermal physical properties and mechanical properties of the coating, and achieve excellent thermal insulation performance and Thermal shock resistance, simple preparation process, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

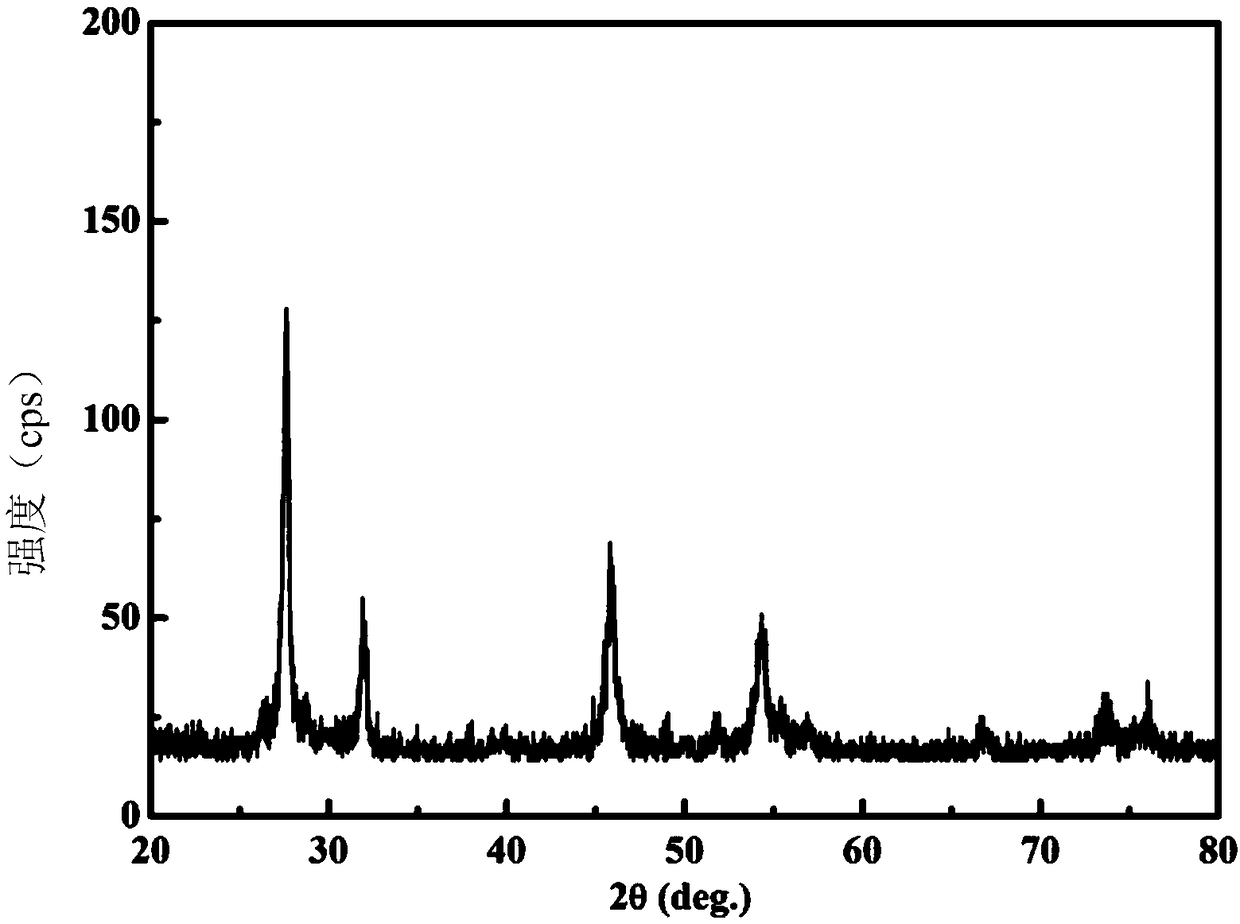

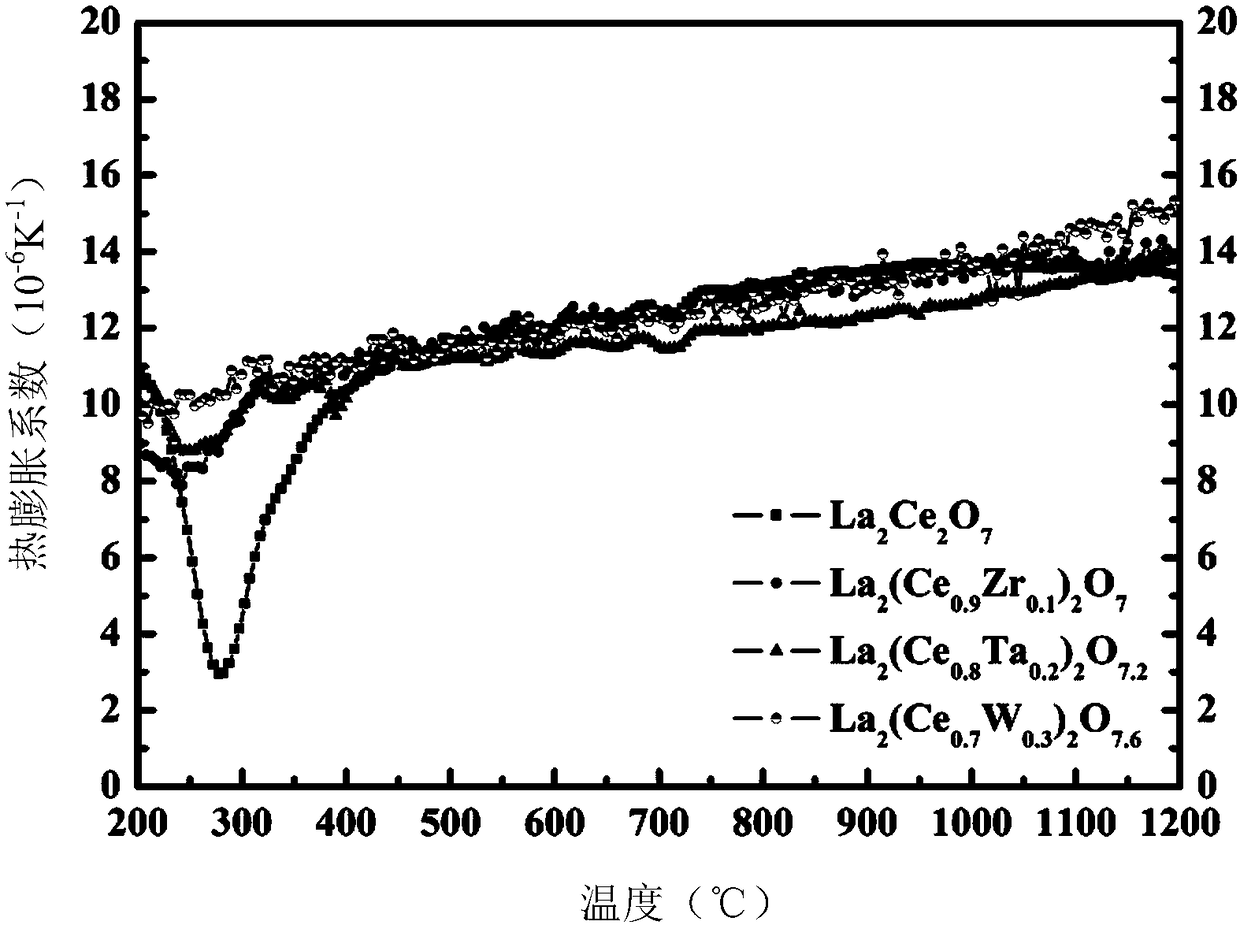

[0035] Embodiment 1: prepare La 2 (Ce 0.9 Zr 0.1 ) 2 o 7 coating

[0036] La(NO with a purity of 99.99% 3 ) 3 ·6H 2 O, Ce(CH 3 COO) 3 , ZrOCl 2 Dissolve in deionized water according to the stoichiometric ratio of La ion: Ce ion: Zr ion=1:0.9:0.1 to prepare a precursor solution, and the molar concentration of La ion in the solution is 1.0mol / L. And add 99.99% pure urea (CO(NH 2 ) 2 ), the addition amount is 10mol.% of the La ion content.

[0037] The precursor solution was stirred for 5 hours with a magnetic stirrer, and then the pH value of the precursor solution was adjusted to 5 with 0.3 mol / L ammonia water, and the ammonia water titration rate was controlled at 0.5 ml / min, and stirred for 5 hours with a magnetic stirrer.

[0038] The prepared precursor solution is sent into the two-fluid atomizing nozzle with a pressure feeding device, and the precursor liquid droplets atomized by the atomizing nozzle are sent into the plasma flame stream. The atomized droplet...

Embodiment 2

[0040] Embodiment 2: prepare La 2 (Ce 0.8 Ti 0.2 ) 2 o 7 coating

[0041] La(CH with a purity of 99.99% 3 COO) 3 , Ce(NO 3 ) 3 ·6H 2 O, Ti(CH 3 COO) 4 Dissolve in deionized water according to the stoichiometric ratio of La ion: Ce ion: Ti ion=1:0.8:0.2 to prepare a precursor solution, and the molar concentration of La ion in the solution is 0.8mol / L. And add ammonium acetate with a purity of 99.99% (CH 3 COONH 4 ), the addition is 40mol.% of the La ion content.

[0042] The precursor solution was stirred for 3 hours with a magnetic stirrer, and then the pH value of the precursor solution was adjusted to 5 with 0.3 mol / L ammonia water, and the titration rate of ammonia water was controlled at 0.5 ml / min, and stirred for 6 hours with a magnetic stirrer.

[0043] The prepared precursor solution is sent into the two-fluid atomizing nozzle with a pressure feeding device, and the precursor liquid droplets atomized by the atomizing nozzle are sent into the plasma flame ...

Embodiment 3

[0045] Embodiment 3: prepare La 2 (Ce 0.7 f 0.3 ) 2 o 7 coating

[0046] La(NO with a purity of 99.99% 3 ) 3 ·6H 2 O, Ce(CH 3 COO) 3 , HfOCl 2 Dissolve in deionized water according to the stoichiometric ratio of La ion: Ce ion: Hf ion=1:0.7:0.3 to prepare a precursor solution, and the molar concentration of La ion in the solution is 1.5mol / L. And add 99.99% pure urea (CO(NH 2 ) 2 ), the addition amount is 30mol.% of the La ion content.

[0047] Stir the precursor solution for 2 hours with a magnetic stirrer, then adjust the pH of the precursor solution to 5 with 0.3 mol / L ammonia water, control the titration rate of ammonia water to 0.5 ml / min, and stir with a magnetic stirrer for 6 hours.

[0048] The prepared precursor solution is sent into the two-fluid atomizing nozzle with a pressure feeding device, and the precursor liquid droplets atomized by the atomizing nozzle are sent into the plasma flame stream. The atomized droplets of the precursor are deposited on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com